Feb . 17, 2025 11:23 Back to list

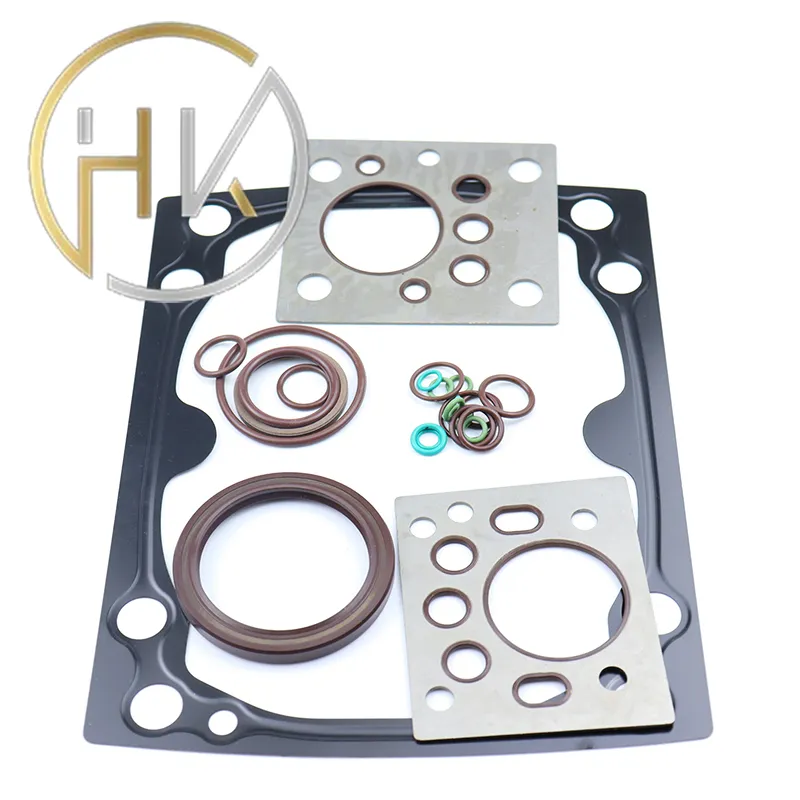

dkb seal

An authoritative grasp of seal kit installation also holds the key to prolonged equipment life. Incorrect installation can compromise the entire hydraulic system, resulting in leaks and mechanical failure. Therefore, consulting with manufacturers' guidelines and possibly even seeking professional installation services can be crucial steps that contribute to the longevity of hydraulic components. Trustworthiness is another cornerstone when discussing cross cylinder seal kits. With numerous manufacturers in the market, distinguishing between sub-par and superior products is essential. Businesses should lean on products with proven track records, supported by customer testimonials and adherence to industry standards. A reputable seal kit supplier typically offers warranties and quality assurances, which underscores their confidence in the product and commitment to customer satisfaction. Real-world experience consistently highlights the correlation between quality seal kits and overall system performance. Companies that prioritize high-standard seal kits often report improved operational efficiency and reduced maintenance costs. This reliable performance allows businesses to focus on growth and productivity, rather than being bogged down by repair and maintenance schedules. To conclude, for those immersed in industries where hydraulic systems are pivotal, expertise in cross cylinder seal kits translates directly into operational success. Quality kits not only guarantee efficient system operations but also affirm the longevity of machinery investments. By trusting in respected manufacturers and employing the right expertise, businesses can ensure that their hydraulic systems remain robust, reliable, and ready to meet the challenges of demanding operational environments.

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

-

Unleash the Power of Your Hydraulic Systems with Our Premium Seal Kits

NewsAug.06,2025

-

Specialized Hydraulic Seal Kits for Breakers, Pistons, and Presses

NewsAug.06,2025

-

Revitalize Hydraulic Systems with Premium Repair and Seal Kits

NewsAug.06,2025

-

Fortify Your Cylinders with Premium Sealing Solutions

NewsAug.06,2025

-

Elevate Hydraulic System Reliability with Specialized Seal Kits

NewsAug.06,2025

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

Products categories