jan . 14, 2025 12:30 Back to list

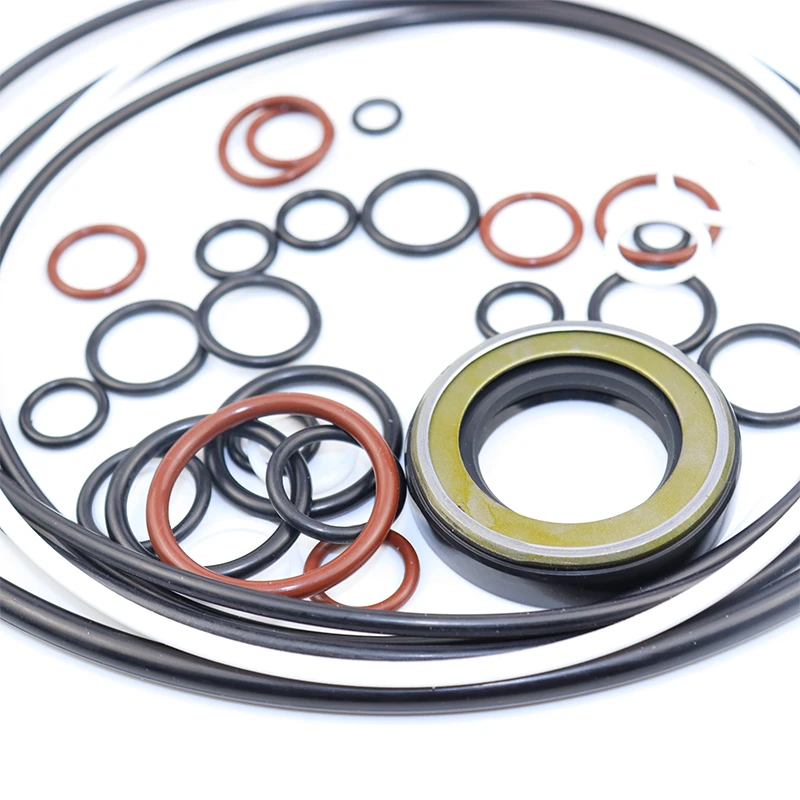

hub seal

In the realm of industrial applications, the role of hub seals extends beyond mere protection against contaminants. They assist in sustaining specific pressure levels within wheel hubs, a critical factor in the efficient operation of equipment like turbines and heavy machinery where pressure stability is directly linked to performance and safety. The authoritative perspective on hub seals also involves continuous innovation and adherence to standards. Manufacturers often invest in research to improve seal design, materials, and technologies that prevent friction and heat build-up, further prolonging seal life and efficiency. Additionally, compliance with industry standards and regulations is an assurance of quality and reliability, factors that customers should prioritize when sourcing seals. Trustworthiness in this context often aligns with selecting reputable manufacturers and suppliers known for stringent quality control processes and robust warranty and service systems. A credible provider should have a history of established partnerships with OEMs and offer thorough aftersales support, including guidance on maintenance and troubleshooting. In summary, hub seals are more than mere protective components—they are foundational to the efficient, safe, and economical operation of vehicles and machinery. Ensuring you are informed about their features, applications, and maintenance can save time, money, and prevent unexpected breakdowns. Whether you're an automotive specialist or industrial operator, a deep understanding of hub seals enhances your ability to maintain peak performance and operational reliability.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories