Rhag . 26, 2024 06:54 Back to list

Essential Guide to Wheel Hub Grease Seals for Optimal Performance and Longevity

Understanding Wheel Hub Grease Seals Importance, Function, and Maintenance

Wheel hub grease seals play a crucial role in the performance and longevity of vehicles. Often overlooked, these components are fundamental in ensuring that the wheel hub assembly works efficiently while protecting internal components from contaminants. This article delves into what wheel hub grease seals are, their functions, the materials they are made from, and maintenance tips to ensure they last as long as needed.

What Are Wheel Hub Grease Seals?

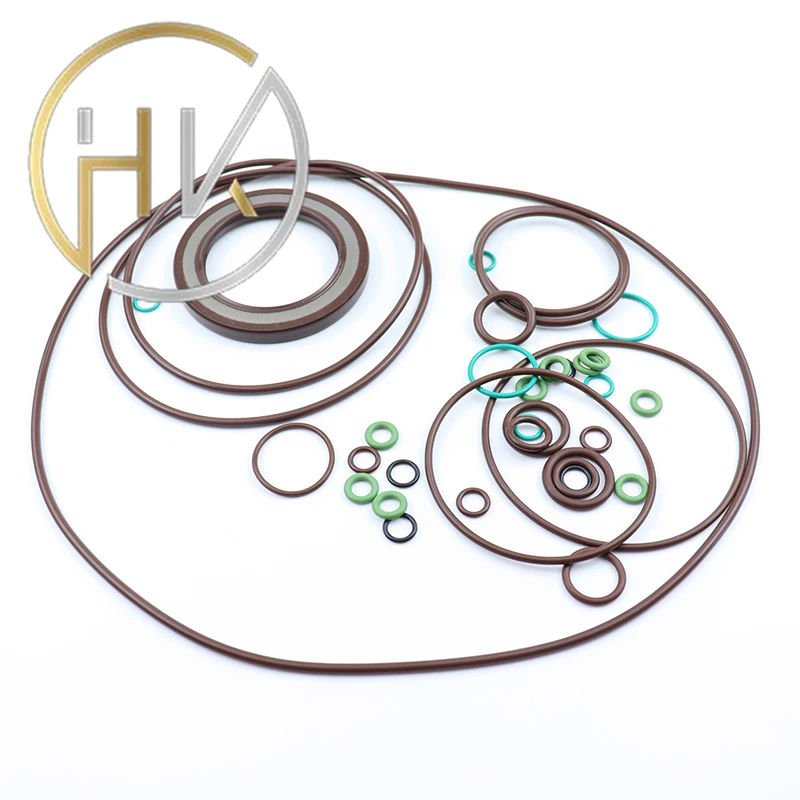

Wheel hub grease seals are circular, rubber or synthetic components designed to fit snugly around the wheel hub. Their primary role is to prevent grease, which lubricates the wheel bearings, from leaking out and to block dirt, water, and other contaminants from entering the hub assembly. This containment of grease is vital as it helps maintain optimal lubrication, which reduces friction and wear on the bearings.

The Function of Wheel Hub Grease Seals

1. Lubrication Retention The primary function of a grease seal is to hold the lubricating grease within the hub. Proper lubrication reduces the incidence of wear and heat generation which can lead to premature failure of the wheel bearings.

2. Contamination Prevention By keeping dirt, moisture, and other foreign particles out, grease seals protect the internal workings of the wheel hub. Contaminants can drastically affect the performance of bearings, leading to wear, corrosion, and eventually the failure of the assembly.

3. Pressure Regulation During vehicle operation, the temperature within the wheel hub can rise, and pockets of grease may expand. Grease seals help manage this pressure, allowing for a safe level of accumulation while ensuring that the grease does not escape.

4. Noise Reduction A well-sealed wheel hub can also contribute to a quieter ride by minimizing vibrations and sounds that could come from the wheel bearings if they are not adequately lubricated or contaminated.

Material Composition

Wheel hub grease seals are typically made of rubber or synthetic polymers. Some common materials include nitrile rubber, silicone, and fluorosilicone, which provide excellent wear resistance and temperature tolerance. The choice of material often depends on the application and operating conditions, such as exposure to extreme temperatures, oils, and other chemicals.

wheel hub grease seal

Signs of Wear and Replacement

Over time, wheel hub grease seals can deteriorate due to constant exposure to harsh conditions, heat, and mechanical stress. Some common signs that a grease seal may need replacement include

- Grease Leakage One of the most obvious signs is the presence of grease on the wheel hub or surrounding components. - Noise Grinding or whining sounds from the wheel hub area may indicate that the bearings are not adequately lubricated. - Heat Excessive heat coming from the wheel hub area can signify a lack of lubrication, potentially due to seal failure.

Maintenance Tips

1. Regular Inspections Check the condition of your grease seals during routine maintenance. Look for cracks or signs of wear that may indicate they need replacing.

2. Proper Installation When replacing grease seals, ensure they are installed correctly. Misalignment can lead to leaks and contamination.

3. Use High-Quality Lubricants Using high-quality grease in the hub assembly can extend the life of both the grease and the seal, reducing the risk of failure.

4. Monitor Driving Conditions Driving in harsh environments—such as off-road or in wet conditions—can accelerate wear. Be vigilant about checking your seals if you're frequently exposed to challenging conditions.

Conclusion

Wheel hub grease seals may seem like minor components, but they are critical for ensuring the smooth operation of your vehicle’s wheel hub assembly. Regular maintenance and timely replacement can save you from costly repairs and enhance your vehicle's performance and safety. By understanding their importance and properly caring for them, you can ensure a longer lifespan for both the seals themselves and the wheel bearings they protect.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories