Tach . 18, 2024 16:40 Back to list

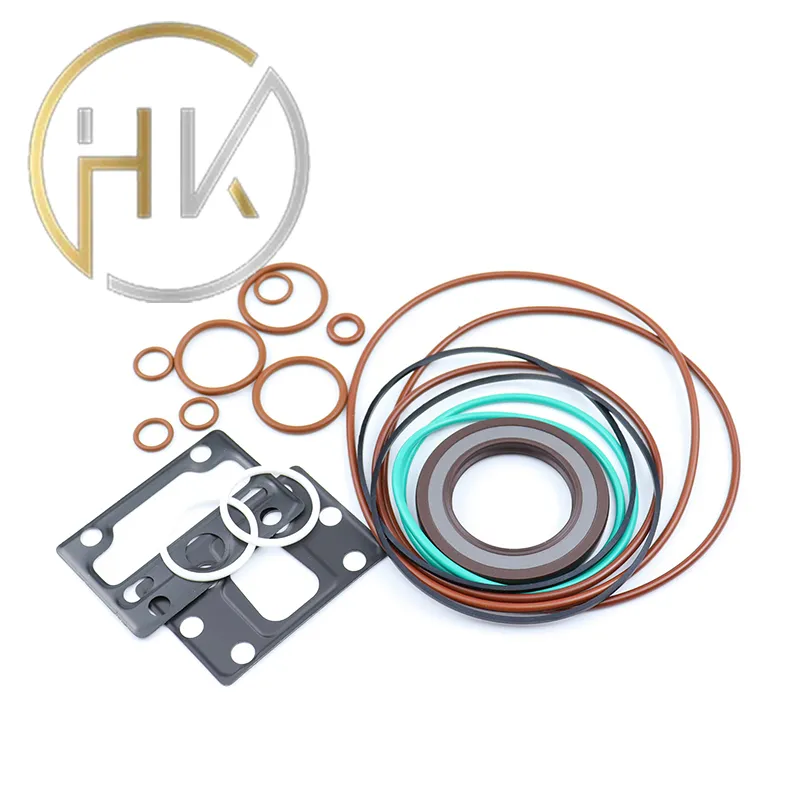

oil seal manufacturer

Understanding Oil Seal Manufacturers The Unsung Heroes of Mechanical Engineering

In the realm of mechanical engineering, the significance of oil seals cannot be understated. These small yet vital components play an integral role in preventing the leakage of lubricants and contaminants, ensuring the longevity and efficiency of machinery. To understand the importance of oil seals, we must delve into the world of oil seal manufacturers—those specialized companies dedicated to the design and production of these indispensable parts.

What is an Oil Seal?

An oil seal, often referred to as a shaft seal, is a mechanical component that seals the interface between a stationary and a moving part. Typically made from elastomers, rubber, or other durable materials, oil seals help prevent the ingress of dust or moisture and the egress of oil and other lubricants. They are used in various applications, including automotive engines, industrial machinery, and other equipment requiring reliable sealing solutions.

The Role of Oil Seal Manufacturers

Oil seal manufacturers specialize in producing these vital components tailored to specific applications. Their expertise revolves around understanding the precise material properties and design specifications required for different operating environments. Factors such as temperature, pressure, exposure to chemicals, and friction play crucial roles in determining the appropriate type of oil seal.

1. Material Selection Oil seal manufacturers utilize a variety of materials, including nitrile rubber (NBR), fluoroelastomer (FKM), and polyacrylate (ACM), depending on the application's requirements. Each material possesses distinct properties, such as temperature resistance and chemical compatibility, which influence the seal's performance.

2. Precision Engineering The manufacturing process involves precise engineering techniques, ensuring that each oil seal meets the demanding specifications set by the industry. High-quality seals are essential for minimizing wear and tear on machinery, ultimately leading to reduced maintenance costs and improved efficiency.

3. Customization Different industries may require custom-designed oil seals to fit unique machinery and operational needs. Manufacturers often work closely with clients to develop bespoke solutions, providing expert consultation to ensure that the selected seals will perform optimally in the intended applications.

4. Quality Control Reputable oil seal manufacturers are committed to maintaining stringent quality control standards. They conduct rigorous testing of materials and finished products to ensure that every oil seal will withstand the rigors of its operation. Certifications and compliance with international standards are critical for manufacturers aiming to serve industries such as automotive, aerospace, and heavy machinery.

oil seal manufacturer

Industries Served by Oil Seal Manufacturers

Oil seals find applications across a multitude of industries, each exhibiting unique requirements

- Automotive In vehicles, oil seals are found in engines, differentials, and transmissions, preventing oil leaks that could lead to significant engine failures.

- Industrial Machinery High-performance machinery, often subjected to harsh operating conditions, relies heavily on oil seals to maintain proper lubrication and prevent contamination.

- Aerospace The aerospace industry demands seals that can function effectively at extreme altitudes and temperatures, making precision manufacturing and quality control essential.

- Agriculture Farming equipment frequently encounters rigorous conditions, necessitating robust oil seals that can withstand dust, moisture, and varying temperatures.

Conclusion

Oil seal manufacturers serve as the backbone of many industries, providing critical components that ensure the seamless operation of machinery and vehicles. Their expertise in material selection, precision engineering, and commitment to quality manifests in the reliability and performance of oil seals. As technology continues to advance and the demands on machinery evolve, the role of these manufacturers will only grow more prominent.

For engineers and procurement specialists alike, choosing the right oil seal manufacturer is imperative. Opting for a reputable manufacturer ensures access to high-quality products that can enhance the efficiency and lifespan of machinery, ultimately leading to significant cost savings and reliable performance. In a world where machinery serves as the lifeblood of industry, oil seals and their manufacturers remain unsung heroes, quietly safeguarding the functionality and integrity of our mechanical systems.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories