Rhag . 01, 2024 03:01 Back to list

Hydraulic Seal Restoration Techniques for Improved Equipment Performance and Longevity

Understanding Hydraulic Seal Repair Importance, Methods, and Best Practices

Hydraulic seals play a crucial role in ensuring the efficient operation of hydraulic systems. They are designed to prevent fluid leakage, maintain pressure, and accommodate movement within hydraulic cylinders and other components. Over time, however, these seals can wear out due to various factors, including environmental conditions, operational stresses, and improper maintenance. When a hydraulic seal fails, it can lead to significant operational issues, including loss of efficiency, increased operational costs, and potential damage to other hydraulic components. Therefore, understanding hydraulic seal repair is vital for maintaining the integrity of hydraulic systems.

Importance of Hydraulic Seal Repair

One of the primary functions of hydraulic seals is to prevent fluid loss. When a seal fails, hydraulic fluid can leak, resulting in decreased pressure and efficiency. This inefficiency can lead to longer operation times, increased energy consumption, and decreased overall productivity. Moreover, leaks can cause environmental hazards and safety concerns, particularly in industries such as manufacturing and construction.

Repairing hydraulic seals promptly can mitigate these issues, prolong the lifespan of the hydraulic system, and reduce operational costs. Moreover, a well-maintained hydraulic system operates more reliably, reducing the likelihood of unexpected breakdowns and repairs.

Common Signs of Seal Failure

Recognizing the signs of hydraulic seal failure is essential for timely repairs. Common indicators include

1. Fluid Leaks Visible fluid around the hydraulic cylinder or components indicates a failed seal.

2. Decreased Performance If the hydraulic system struggles to perform tasks it usually handles, it may signal seal wear.

3. Noise Unusual sounds during operation, such as grinding or whining, can indicate issues with seals or other parts.

4. Pressure Drops A decrease in system pressure can often be traced back to compromised seals.

Methods of Hydraulic Seal Repair

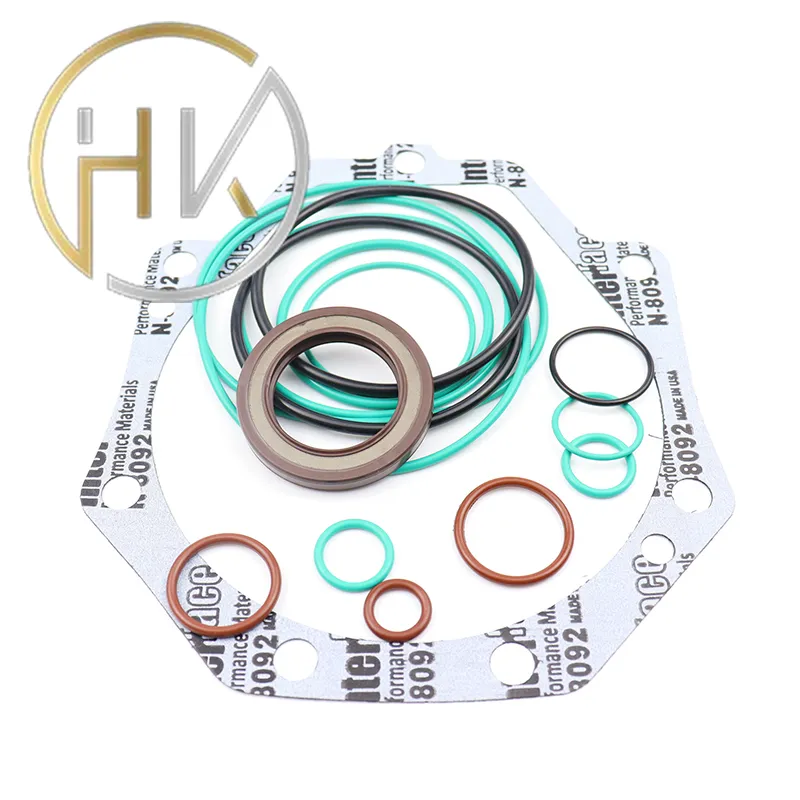

hydraulic seal repair

There are several methods for repairing hydraulic seals, and the approach typically depends on the extent of the damage and the specific application. Below are common repair methods

1. Seal Replacement This is often the most straightforward approach. Removing the damaged seal and replacing it with a new one ensures that the system returns to optimal performance.

2. Reconditioning Components In some cases, instead of replacing seals, components can be reconditioned. This process involves cleaning, polishing, and resurfacing to create a better fit for new seals.

3. Using Sealant Products For minor leaks, specific sealants can be applied to the affected area to prevent further leakage. However, this is often a temporary solution rather than a permanent fix.

4. System Flushing Dirt or debris can get trapped and cause seals to wear out faster. Flushing the hydraulic system helps eliminate contaminants and can extend the lifespan of seals.

Best Practices for Hydraulic Seal Maintenance

To prolong the life of hydraulic seals and reduce the need for repairs, consider the following best practices

1. Regular Inspections Conducting routine checks on hydraulic systems can help identify potential issues early.

2. Maintain Cleanliness Keeping the hydraulic environment clean reduces the risk of contaminants damaging seals.

3. Proper Operation Avoid overloading or misusing hydraulic systems, as this can lead to premature seal failure.

4. Use Quality Parts Always use high-quality seals and components that meet the specifications of your hydraulic system.

In conclusion, understanding hydraulic seal repair is essential for anyone involved in the management and operation of hydraulic systems. By recognizing the signs of seal failure, employing effective repair methods, and following best maintenance practices, operators can ensure the reliability and efficiency of their hydraulic systems, minimizing downtime and maximizing productivity.

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

-

Unleash the Power of Your Hydraulic Systems with Our Premium Seal Kits

NewsAug.06,2025

-

Specialized Hydraulic Seal Kits for Breakers, Pistons, and Presses

NewsAug.06,2025

-

Revitalize Hydraulic Systems with Premium Repair and Seal Kits

NewsAug.06,2025

-

Fortify Your Cylinders with Premium Sealing Solutions

NewsAug.06,2025

-

Elevate Hydraulic System Reliability with Specialized Seal Kits

NewsAug.06,2025

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

Products categories