Tach . 24, 2024 22:09 Back to list

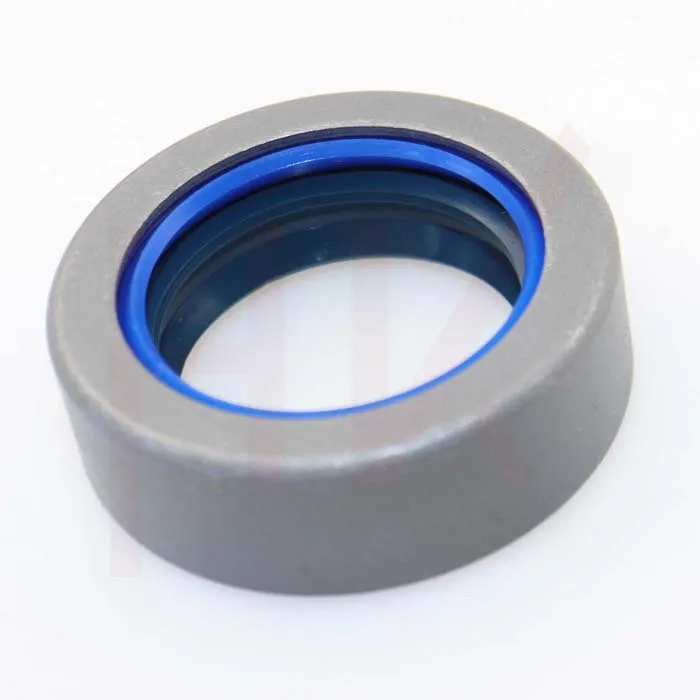

35 72 10 oil seal

Exploring the Importance of the 35% 2072 2010 Oil Seal A Critical Component in Machinery

In the world of machinery and automotive engineering, components play a crucial role in ensuring efficiency and functionality. Among these components, oil seals are integral to maintaining the performance and durability of machines. One particular oil seal that stands out is the 35% 2072 2010 oil seal. This article delves into the significance of this specific oil seal, its functions, and its applications in various industries.

What is an Oil Seal?

An oil seal, also known as a grease seal, is a device used to seal the lubricants in machinery, preventing them from leaking out and keeping contaminants from entering. Typically made from rubber or other elastomeric materials, oil seals form a barrier between moving parts, particularly in rotating shafts. They play a vital role in prolonging the life of machinery by ensuring that lubricants remain where they are needed, thereby reducing friction and wear.

The Specifications 35% 2072 2010 Oil Seal

The designation 35% 2072 2010 likely represents a specific type of oil seal with distinctive dimensions and properties, which are essential for specific applications. The numbers might indicate the diameter of the seal, its thickness, and other critical parameters that define its fit and performance in particular machinery or automotive systems. Understanding these specifications is crucial for engineers and technicians when replacing or selecting an oil seal to ensure compatibility and optimal function.

Applications of the 35% 2072 2010 Oil Seal

The versatility of the 35% 2072 2010 oil seal allows it to be utilized across various industries. Here are some common applications

1. Automotive Industry In automobiles, oil seals are used in engines, transmissions, and differentials to prevent oil leakage and lubricate components. The 35% 2072 2010 oil seal is particularly suited for engines that demand high performance, as it can withstand significant pressure and high temperatures, ensuring reliability over time.

35 72 10 oil seal

2. Industrial Machinery In manufacturing and industrial settings, machines such as pumps, compressors, and generators rely on oil seals to maintain operational integrity. The 35% 2072 2010 oil seal helps prevent contamination by dust and dirt, which can lead to equipment failure and costly repairs.

3. Aerospace Applications The aerospace industry also employs oil seals, including the 35% 2072 2010 variant, to protect critical components in aircraft systems. Given the rigorous standards of safety and performance in this sector, the reliability of oil seals is paramount.

4. Construction Equipment Heavy machinery used in construction, such as excavators and bulldozers, depends on robust oil seals to ensure hydraulic systems operate smoothly. The 35% 2072 2010 oil seal serves as a protective barrier, helping to enhance the lifespan of the machinery.

Why Choose the 35% 2072 2010 Oil Seal?

Selecting the right oil seal is critical for optimal machinery performance. The 35% 2072 2010 oil seal offers several advantages

- Durability Made from high-quality materials, this oil seal is designed to withstand extreme conditions, including temperature variations and chemical exposure, which are common in industrial applications. - Performance With its precise dimensions, the 35% 2072 2010 oil seal ensures a tight fit, reducing the risk of leaks and improving the operational efficiency of the machinery in which it is installed.

- Cost-Effectiveness By preventing leaks and contamination, this oil seal helps reduce maintenance costs and downtime, making it a worthwhile investment for businesses operating in competitive environments.

Conclusion

In conclusion, the 35% 2072 2010 oil seal is an essential component that plays a vital role across various industries, particularly in automotive, industrial, aerospace, and construction applications. Its durability, performance, and cost-effectiveness make it a preferred choice for engineers and technicians looking to maintain the integrity and efficiency of machinery. As industries continue to evolve, the demand for reliable oil seals like the 35% 2072 2010 will only grow, underscoring the importance of this critical component in the modern world.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories