Úno . 05, 2025 04:46 Back to list

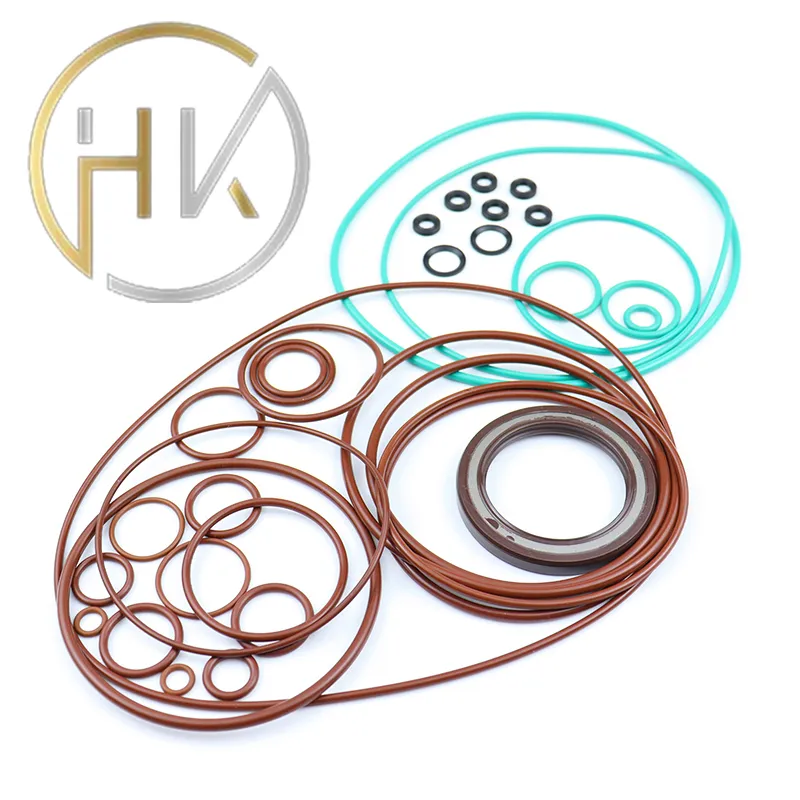

170×190×13 Tcv Oil Seal High Pressure Oil Seal Hydraulic Pump Seal

Demonstrating authoritativeness, professionals stress the significance of precise installation and maintenance. Without proper installation, even the most advanced dust seals can fail prematurely. Misalignment during installation can generate gaps, negating the seal's protective properties. Regular inspection is also paramount; early detection of wear and tear can prompt timely replacements, prolonging the machine's operational lifespan. Trustworthiness in product performance often comes from proven brands, which consistently deliver seals that adhere to industry standards and stringent quality checks. For instance, seals that comply with ISO or other relevant standards provide a level of assurance regarding their capabilities. Endorsements from industry experts or certifications can significantly bolster a product's credibility. In summary, shaft dust seals, though often overlooked, are pivotal to safeguarding machinery from particulate contaminants. Their installation and maintenance demand a blend of technical know-how and practical expertise to cater to specific application requirements. For any machinery reliant on smooth and uninterrupted operations, shaft dust seals are an indispensable investment that preserves integrity, reduces downtime, and enhances overall efficiency.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories