Lis . 16, 2024 15:33 Back to list

Understanding the Function and Importance of Rotary Oil Seals in Machinery

Understanding Rotary Oil Seals Essential Components for Machinery

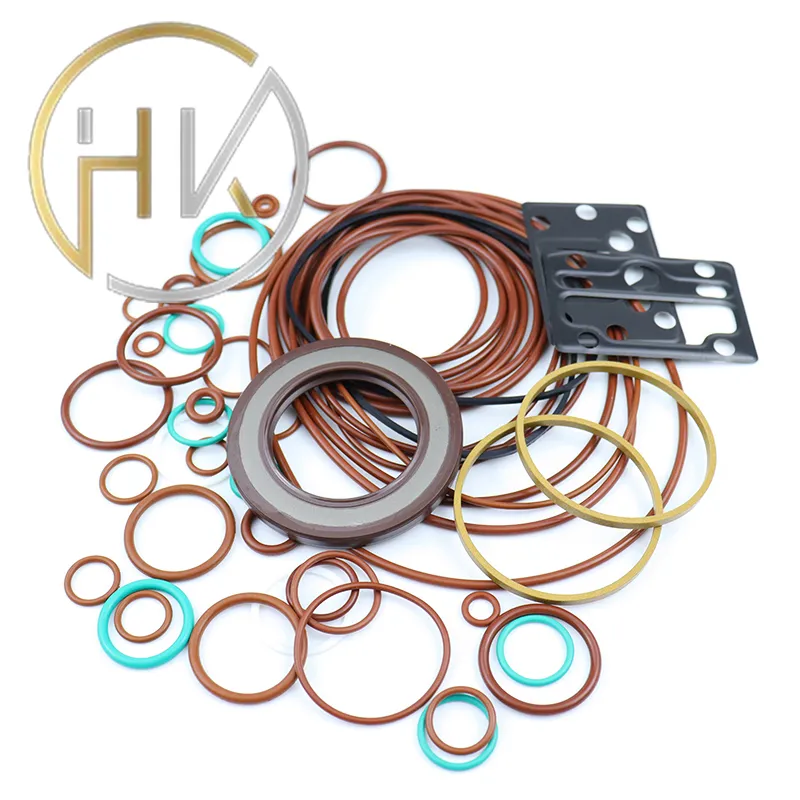

Rotary oil seals, also commonly referred to as rotary shaft seals or lip seals, play a crucial role in a wide range of machinery and equipment by preventing the leakage of lubricants and contaminants. These seals are especially vital in rotating applications where shafts or axles are involved, providing a barrier between the rotating part and the surrounding environment.

Structure and Design

The basic structure of a rotary oil seal consists of three primary components the sealing lip, the outer casing, and a reinforcement ring. The sealing lip is often made from elastomeric materials, such as nitrile rubber or fluorocarbon, which allows it to deform slightly, ensuring a tight fit against the rotating shaft. The outer casing, typically metal, is designed to secure the seal inside the housing, while the reinforcement ring enhances the seal's strength and flexibility.

The design of rotary oil seals is tailored to withstand various operating conditions, including temperature fluctuations, pressure variations, and exposure to different chemicals. Manufacturers produce these seals in various sizes and designs to cater to the specific needs of different machinery, whether for automotive engines, hydraulic pumps, or industrial equipment.

Functionality

The primary function of rotary oil seals is to retain lubricant within the machinery while keeping dirt, dust, and moisture outside the system. By doing so, they help to maintain optimal lubrication, which is essential for reducing friction and wear on moving parts. This function not only prolongs the lifespan of the equipment but also ensures efficient operation, ultimately leading to lower maintenance costs and reduced downtime.

Moreover, rotary oil seals are designed to operate under high speeds and pressures, making them suitable for dynamic applications

. The sealing lip's ability to compensate for wear and thermal expansion further contributes to their efficiency and reliability.rotary oil seals

Types of Rotary Oil Seals

Rotary oil seals can be classified into several types based on their design and material composition. Common types include

1. Standard Lip Seals These are the most widely used seals, featuring a single lip designed for general-purpose applications. 2. Double-Lip Seals Equipped with two sealing lips, these seals offer enhanced protection against contamination and fluid leakage.

3. Spring-Loaded Seals These seals include a spring mechanism that applies additional pressure on the sealing lip, improving the seal's performance under high-speed conditions.

4. Customized Seals For specific applications, manufacturers can create tailored seals based on unique requirements, such as size, material, and environmental factors.

Maintenance and Replacement

While rotary oil seals are designed to be durable, they do require periodic inspection and replacement to ensure optimal performance. Signs of wear, such as oil leakage or increased friction, indicate that a seal may need to be replaced. Proper installation and alignment are also crucial, as incorrect installation can lead to premature seal failure.

In conclusion, rotary oil seals are indispensable components in various mechanical systems, ensuring efficient operation and preventing leaks. Understanding their design, function, and types can help in selecting the appropriate seal for specific applications, thereby enhancing machinery performance and longevity. Regular maintenance and timely replacement are essential practices to keep these crucial seals functioning effectively, ultimately ensuring the reliability of the equipment they protect.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories