Pro . 04, 2024 09:38 Back to list

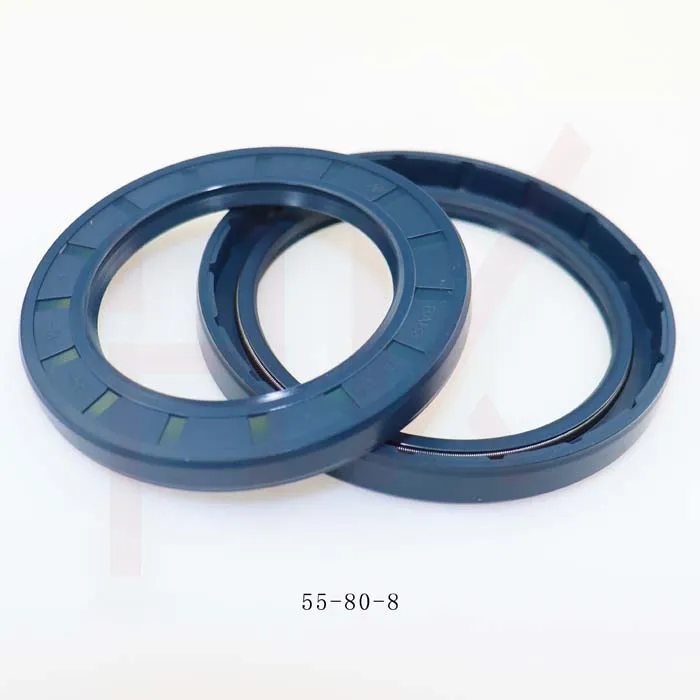

inner hub seal

Inner Hub Seal Importance and Applications in Modern Engineering

In the world of engineering and mechanics, seals play a critical role in ensuring the integrity and efficiency of various systems. Among the many types of seals utilized in different applications, the inner hub seal stands out due to its specific functions and advantages. This article delves into the significance of inner hub seals, their construction, applications, and the benefits they provide in modern engineering.

Understanding Inner Hub Seals

An inner hub seal is a type of sealing device commonly found in rotating machinery, particularly in applications involving wheels and axles, such as vehicles. The primary function of the inner hub seal is to prevent the ingress of contaminants like dirt, water, and debris into the hub assembly while simultaneously keeping lubricants within the hub. This sealing action is crucial for maintaining optimal operational conditions and prolonging the lifespan of mechanical components.

Construction of Inner Hub Seals

Typically made from durable materials such as rubber, polyurethane, or silicone, inner hub seals are designed to withstand various environmental conditions and mechanical stresses. The construction often features a flexible lip that creates a barrier against external elements while conforming to the rotating shaft. This unique design allows for minimal friction and wear during operation, further contributing to the seal's longevity and effectiveness.

In addition to the primary sealing lip, inner hub seals may also include secondary features such as dust shields or additional sealing elements to provide extended protection. The combination of these design elements ensures a robust sealing solution that can handle the rigors of high-speed rotation and varying temperatures.

Applications of Inner Hub Seals

Inner hub seals are predominantly used in the automotive industry, particularly in the manufacture of vehicles. They are commonly found in wheel hubs, where they play a vital role in maintaining the integrity of bearings and ensuring smooth wheel rotation. In this context, they prevent the ingress of moisture and contaminants that could lead to premature wear or failure of critical components.

inner hub seal

Beyond automotive applications, inner hub seals are also utilized in various industrial machinery, including motors, pumps, and gearboxes. Any rotating assembly that requires protection from external contaminants while retaining lubricants can benefit from the use of an inner hub seal. This versatility makes them an essential component in multiple sectors, including manufacturing, aerospace, and robotics.

Benefits of Using Inner Hub Seals

The advantages of implementing inner hub seals in mechanical systems are numerous

1. Enhanced Longevity By preventing contamination and retaining lubricants, inner hub seals significantly extend the lifespan of mechanical components, reducing the need for frequent maintenance and replacements.

2. Improved Efficiency A properly sealed hub assembly operates more efficiently due to reduced friction and resistance, leading to improved overall performance in machinery and vehicles.

3. Cost-Effectiveness Although the initial investment in high-quality inner hub seals may be higher, the long-term savings generated from decreased maintenance and downtime can be substantial.

4. Versatility Inner hub seals can be tailored to fit various applications and can be designed to withstand specific environmental conditions, making them suitable for a wide range of industries.

Conclusion

Inner hub seals are a vital component in ensuring the reliability and efficiency of numerous mechanical systems. Their ability to protect against contamination while retaining essential lubricants makes them indispensable in automotive and industrial applications. As technology continues to evolve, the design and materials used for inner hub seals will likely advance, allowing for even greater performance and durability in the face of challenging conditions. In a world where efficiency and reliability are paramount, inner hub seals play an unobtrusive yet crucial role in the machinery that powers our lives.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories