Pro . 10, 2024 13:14 Back to list

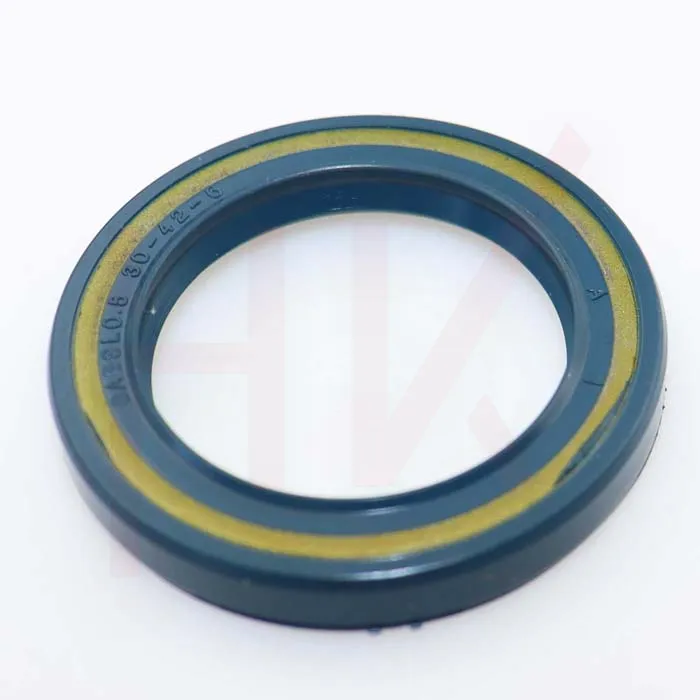

high pressure pump seal kit

Understanding High Pressure Pump Seal Kits

High pressure pump seal kits play a critical role in ensuring the efficient operation and longevity of pumps used in various industrial applications. These kits are specifically designed to manage and contain the pressures generated within these pumps, preventing leaks and maintaining optimal performance. In this article, we will explore what high pressure pump seal kits are, their components, the importance of maintenance, and how to select the right kit for your needs.

What is a High Pressure Pump Seal Kit?

A high pressure pump seal kit contains essential components used to repair or replace the seals within high-pressure pumps. These seals are essential in preventing fluid leakage between pump components, such as the rotor and the casing, thereby maintaining operational efficiency and safety. High pressure applications, typical in industries like oil and gas, chemical processing, and water treatment, require robust sealing solutions that can withstand extreme conditions.

Components of a Seal Kit

Typically, a seal kit will include various components designed to handle the specific requirements of high pressure pumps

1. Mechanical Seals These are the primary components designed to prevent leakage. Mechanical seals use a combination of rotating and stationary elements to create a fluid-tight barrier, often made from durable materials such as carbide, ceramic, or elastomers.

2. O-Rings These circular seals fit into grooves and are essential for sealing between components. They can be made from various materials, including rubber or silicone, to withstand different chemical and temperature environments.

3. Gaskets Used for sealing between flanged connections, gaskets prevent leakage of fluids under pressure. Choosing the right gasket material is crucial, as it must be compatible with the fluids being pumped.

4. Backup Rings These support O-rings in high-pressure applications, preventing them from extruding under pressure and enhancing the seal's longevity.

5. Lubricants and Sealants Some kits may also include specialty lubricants or sealants to aid in installation and improve sealing performance.

Importance of Maintenance

Regular maintenance of high pressure pump seal kits is vital for several reasons

high pressure pump seal kit

- Preventing Leaks Over time, seals can wear out or become damaged, leading to leaks that can compromise safety and efficiency. Regular inspections and timely replacements can prevent significant downtime and costly repairs.

- Extending Pump Life Properly maintained seals reduce the strain on pump components, leading to longer operational life for the pump itself.

- Enhancing Efficiency Leaks can cause loss of pressure and reduce the overall efficiency of the pump. Keeping seals in good condition helps maintain optimal operational parameters.

- Safety and Compliance Many industries have stringent regulations regarding leak prevention. Maintaining high pressure pump seals ensures compliance and promotes operational safety.

How to Select the Right Seal Kit

Choosing the right high pressure pump seal kit involves several considerations

1. Pump Model and Type Ensure that the kit is compatible with your specific pump model. Manufacturers often provide detailed specifications for seal kits.

2. Operating Conditions Consider the operating temperature, pressure range, and the type of fluid being pumped. Different materials have varying capabilities and compatibilities with fluids.

3. Quality and Certifications Look for kits from reputable manufacturers that meet industry standards and certifications. Quality kits will often yield better performance and longer service life.

4. Installation Requirements Some seals may require specific tools or methods for installation. Familiarize yourself with how the kit is to be installed and the maintenance procedures required.

Conclusion

High pressure pump seal kits are indispensable for the reliability and efficiency of pumps in demanding applications. Understanding their components, importance of maintenance, and selection criteria will help operators make informed decisions that enhance pump performance and lifespan. By investing in quality seal kits and adhering to maintenance protocols, industries can safeguard their operations against leaks and ensure their equipment runs smoothly under high pressure conditions.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories