Pro . 16, 2024 18:41 Back to list

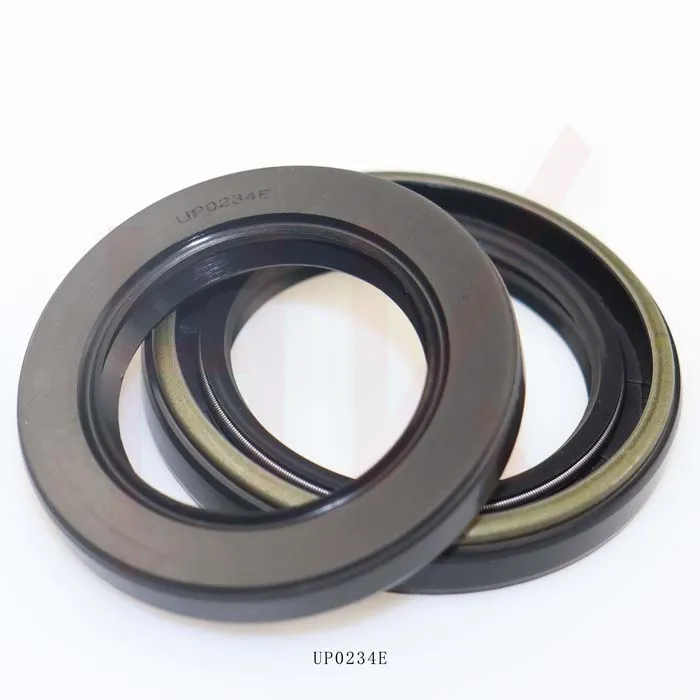

cylinder rod wiper

Understanding Cylinder Rod Wipers Importance and Selection

Cylinder rod wipers are crucial components in hydraulic and pneumatic systems, ensuring efficient operation and extending the service life of equipment. These wipers are designed to prevent contaminants from entering the cylinder, thus maintaining clean and smooth operation of the rod and associated mechanisms. The significance of wipers cannot be overstated, especially considering the environments in which hydraulic cylinders often operate, where dust, dirt, moisture, and other foreign particles can lead to wear and failure.

The Role of Cylinder Rod Wipers

The primary function of a cylinder rod wiper is to keep the rod clean as it extends and retracts. When a hydraulic or pneumatic cylinder operates, the rod moves in and out of the cylinder body. As it does so, it can pick up debris and contaminants from the surrounding environment. If these particles enter the cylinder, they can damage seals, cause premature wear, and potentially lead to system failures.

Additionally, wipers also help manage fluid leakage and maintain pressure within the cylinder systems. By providing a sealing effect at the rod’s exit point, wipers can help minimize fluid loss, ensuring that the system operates efficiently and effectively.

Materials and Design

Cylinder rod wipers are made from various materials, each offering distinct advantages based on the application's specific needs. Common materials include polyurethane, rubber, and nylon.

1. Polyurethane Known for its excellent wear resistance and flexibility, polyurethane wipers are often utilized in harsh environments due to their durability. They are also resistant to oils and chemicals, making them suitable for a range of industries, including automotive and industrial machinery.

2. Rubber Rubber wipers are typically more economical and provide good sealing properties. However, their resistance to wear and chemicals may not be as robust as polyurethane, which can limit their application in more demanding environments.

3. Nylon Though less common for wipers, nylon is sometimes used for its low friction properties and ability to withstand a range of temperatures. It is typically chosen for specific applications where high wear resistance is not as critical.

cylinder rod wiper

The design of the wiper itself can also vary. Some are designed with lips to effectively scrape and remove debris from the rod while others may have specific shapes and contours to enhance sealing capabilities. The choice of design will depend on the operational environment and the level of contamination the cylinder might experience.

Selecting the Right Wiper

In selecting the appropriate cylinder rod wiper, several factors need to be considered

- Operating Environment Assess the environment where the cylinder will be used. High dust and dirt exposure may necessitate a more robust material, while cleaner environments might allow for cost-effective options.

- Temperature and Chemical Exposure Evaluate the temperature range and any chemicals the wiper might contact. Ensure that the material selected can withstand these conditions without degrading.

- Rod Diameter and Design Ensure that the wiper fits properly onto the rod diameter and matches any design specifications of the cylinder. Proper fit is crucial for effective sealing and debris scraping.

- Operational Speed The speed at which the cylinder operates can impact the selection of the wiper. Faster-moving rods may require wipers designed for higher performance under dynamic conditions.

Maintenance and Replacement

Regular maintenance and timely replacement of cylinder rod wipers are essential for prolonging the lifespan of hydraulic and pneumatic systems. Wear and tear on wipers can lead to compromised sealing, increasing the risk of contamination and fluid loss. Signs that wipers need attention include visible wear, cracking, or if there are leaking fluids around the cylinder.

In conclusion, cylinder rod wipers play a pivotal role in maintaining the efficiency and reliability of hydraulic and pneumatic systems. By understanding their importance, selecting the right materials, and performing regular maintenance, you can ensure optimal performance and extend the lifespan of your equipment. Through careful selection and attentive maintenance, businesses can enjoy the benefits of increased productivity and reduced downtime, driving long-term success in their operations.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories