Lis . 28, 2024 07:59 Back to list

Cylinder Oil Seal Types and Applications in Machinery Maintenance and Repair

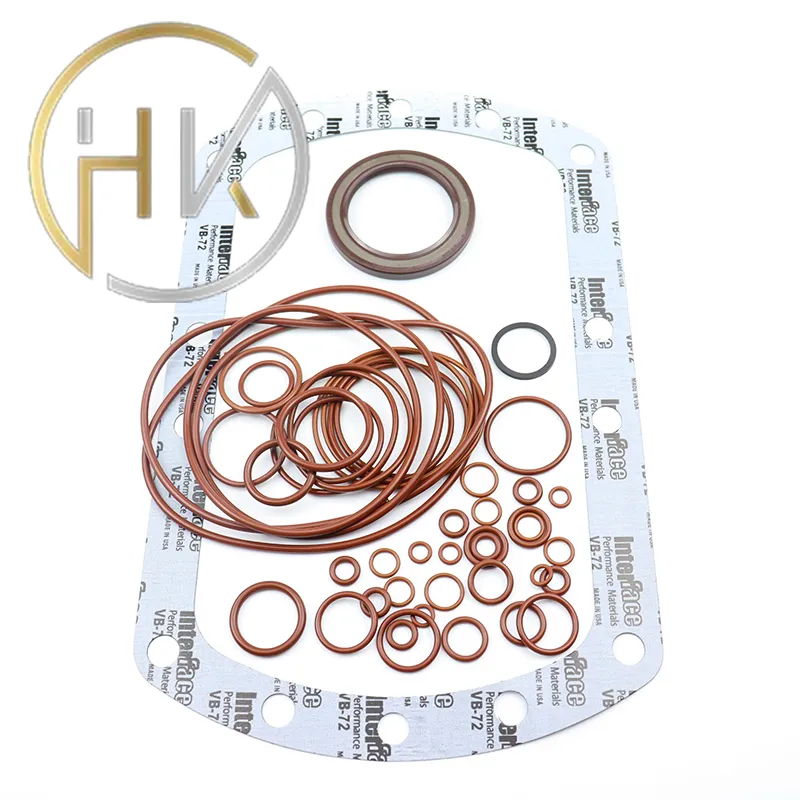

Understanding Cylinder Oil Seals An Essential Component for Engine Efficiency

Cylinder oil seals, commonly referred to as simply oil seals, play a critical role in ensuring the efficiency and longevity of an engine. These small yet vital components are designed to prevent oil leakage and protect engine parts from contamination. Understanding their construction, function, and maintenance can help vehicle owners and mechanics alike appreciate their importance in engine performance.

What is a Cylinder Oil Seal?

A cylinder oil seal is a mechanical device that consists of a flexible rubber material (or another elastomer) and a metal casing. It fits into a groove on the engine cylinder and forms a barrier between the internal moving parts and the external environment. The primary function of the oil seal is to retain oil within the cylinder while simultaneously preventing dirt, dust, and other contaminants from entering.

The Importance of Cylinder Oil Seals

1. Oil Retention One of the most critical functions of the cylinder oil seal is to prevent oil from leaking from the engine. Oil is essential for lubricating the moving parts, ensuring smooth operation, and minimizing wear and tear. A leak can lead to inadequate lubrication, causing increased friction, overheating, and ultimately, engine failure.

2. Contamination Prevention Oil seals also serve as barriers to contaminants. Without these seals, dust and debris can enter the engine. Such contamination can reduce the efficacy of the oil and promote wear on components, leading to potentially severe damage over time.

3. Improved Efficiency By maintaining the integrity of the oil system and preventing leaks, cylinder oil seals help enhance fuel efficiency. When the engine can operate smoothly without the loss of lubricants or the intrusion of contaminants, it performs more efficiently, providing better fuel economies and smoother operation.

Types of Cylinder Oil Seals

There are various types of cylinder oil seals, each designed for specific applications and operating conditions. The most common types include

cylinder oil seal

1. Single Lip Oil Seals These seals have a single sealing lip that compresses against the shaft. They are commonly used in applications with lower rotational speeds and moderate pressures.

2. Double Lip Oil Seals Featuring two sealing lips, these seals provide better protection against contaminants and are ideal for more demanding environments. The additional lip helps in preventing oil loss more effectively.

3. Spring-Loaded Seals Some oil seals come with a metal spring that applies additional pressure on the sealing lip, enhancing the seal's ability to retain oil even under high-pressure conditions.

Installation and Maintenance

To ensure optimal performance, proper installation and maintenance of cylinder oil seals are vital. Here are some tips

- Correct Sizing Always ensure that the oil seal is the correct size for the application. An improperly sized seal may lead to leaks or excessive wear.

- Installation Technique When installing an oil seal, it is crucial to avoid damaging the lip. Use appropriate tools and techniques, ensuring the seal is seated correctly without forcing it into place.

- Regular Inspection Periodically inspect the cylinder oil seals for signs of wear, such as cracking, fraying, or hardening. Early detection of seal issues can prevent more extensive engine damage and costly repairs.

Conclusion

In summary, cylinder oil seals are integral components that ensure the efficient functioning of engines. From retaining crucial oil supplies to preventing contaminants from entering the engine's interior, their importance cannot be overstated. Understanding the types, functions, and maintenance practices for these seals can help engine owners achieve optimal performance and longevity for their vehicles. Regular checks and timely replacements of worn oil seals can save drivers from expensive repairs and keep engines running smoothly for years to come. Whether you are a vehicle owner or a mechanic, recognizing the value of cylinder oil seals is essential for maintaining engine health and performance.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories