Pro . 21, 2024 01:27 Back to list

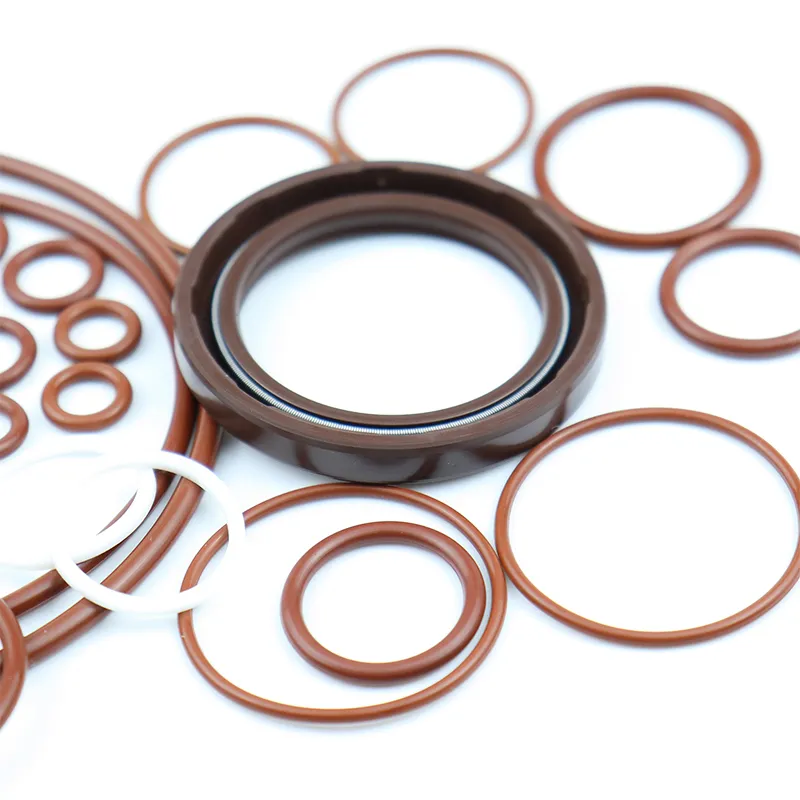

bottle jack seal kit

The Importance of a Bottle Jack Seal Kit for Maintenance and Longevity

A bottle jack is an essential tool for anyone who requires lifting heavy loads with ease, whether it be in an automotive garage, construction site, or a home workshop. However, like any mechanical device, bottle jacks can be prone to wear and tear, particularly in the sealing components. This brings us to the critical topic of a bottle jack seal kit and its importance in maintaining your equipment.

Understanding Bottle Jacks

Bottle jacks, known for their compact design and high lifting capacity, operate on hydraulic principles. They rely on hydraulic fluid to generate the necessary force to lift heavy objects. Essential to their operation are the seals within the system, which prevent fluid leaks and ensure smooth functioning. A well-maintained bottle jack can perform efficiently for years, but neglecting the seals can lead to significant issues, including reduced lifting power, leaks, and even complete failure.

What is a Bottle Jack Seal Kit?

A bottle jack seal kit comprises various components designed to replace worn or damaged seals in a bottle jack. The kit typically includes a range of seals, O-rings, and backup rings that fit specific models of bottle jacks. Using a seal kit allows users to restore the hydraulic system to optimal functionality without having to invest in a completely new jack, thus saving time and money.

Why Choose a Seal Kit?

1. Cost-Effective Solution Purchasing a seal kit is significantly cheaper than buying a new bottle jack. During regular use, seals can become worn due to friction and exposure to contaminants. Instead of discarding the entire unit, a seal kit allows users to replace the defective parts, maintaining functionality without a hefty price tag.

2. Enhanced Safety A bottle jack that has leaking hydraulic fluid poses a safety hazard. The loss of pressure can lead to instability when lifting heavy loads, risking injury or accidents. By regularly replacing seals using a seal kit, you ensure that your jack operates safely and effectively, providing peace of mind during use.

3. Improved Performance Regular maintenance, including the replacement of seals, ensures that the bottle jack operates at peak performance. A well-sealed hydraulic system can achieve the desired lifting capacity with minimal effort, making your work more efficient and reducing fatigue.

bottle jack seal kit

How to Install a Bottle Jack Seal Kit

Installing a seal kit is a relatively straightforward process, but it does require some mechanical aptitude. Here’s a basic overview of the steps involved

1. Preparation Ensure that you have the right seal kit for your specific model of bottle jack. Gather necessary tools, such as wrenches, screwdrivers, and a clean work surface.

2. Disassemble the Jack Carefully disassemble the bottle jack, starting from the base while taking note of the order of components. This will be essential when reassembling the jack.

3. Remove Old Seals Once disassembled, extract the old seals and inspect the internal components for any additional wear. Clean all parts to remove any debris or old hydraulic fluid.

4. Install New Seals Begin installing the new seals from the kit, ensuring they are seated properly to prevent leaks. Refer to the instructions included in the kit, as proper orientation and placement are crucial.

5. Reassembly Carefully reassemble the jack in the reverse order of disassembly. Be sure all components are tight and secure.

6. Testing Once reassembled, add hydraulic fluid and test the jack to ensure it operates smoothly without leaks.

Conclusion

In summary, a bottle jack seal kit is an invaluable investment for anyone who relies on lifting equipment regularly. By ensuring proper maintenance through the replacement of worn seals, you can extend the life of your bottle jack, enhance safety, and improve overall performance. Regularly checking and replacing seals will not only save you money but will also ensure that your lifting tasks are completed efficiently and safely. Don't overlook the importance of this simple yet vital component in your hydraulic lifting arsenal.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories