Lis . 25, 2024 01:29 Back to list

Alternative Oil Seal Specifications with 35% 2047 and 7 Measurements

Understanding the 35% 2047 7 Oil Seal A Comprehensive Guide

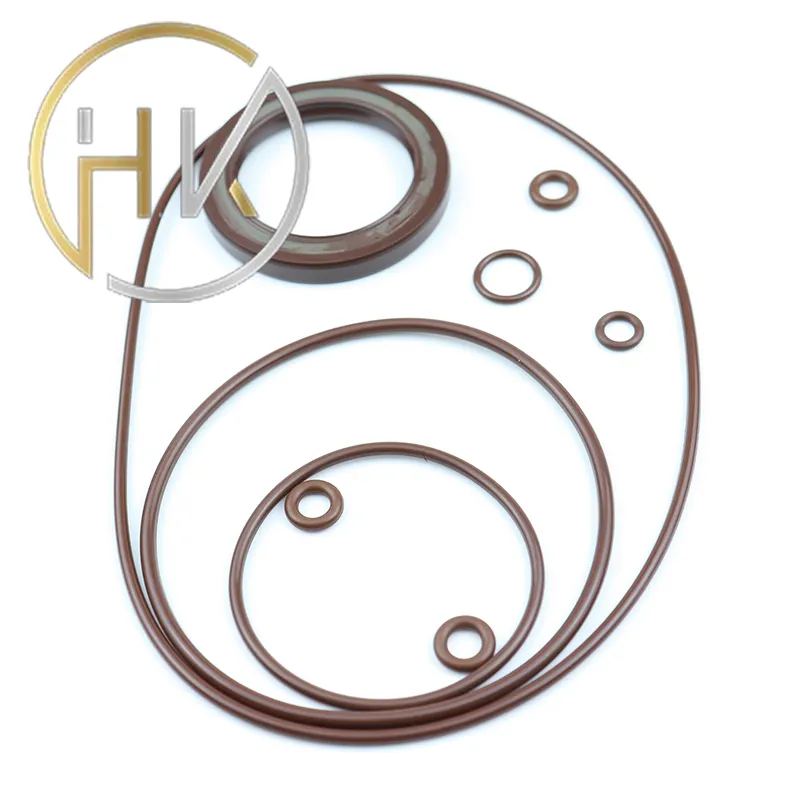

Oil seals, also known as oil seals or simply seals, play a pivotal role in machine functionality and performance. Among the myriad types of oil seals available in the market, the 35% 2047 7 oil seal stands out due to its unique specifications and applications. In this article, we will delve into the significance, construction, materials, and applications of the 35% 2047 7 oil seal, providing a thorough understanding for engineers, mechanics, and industry professionals.

What is an Oil Seal?

An oil seal is a crucial component used in machinery to prevent lubricant leakage while also protecting the internal components from external contaminants like dust, dirt, and moisture. The primary purpose of an oil seal is to provide a sturdy barrier that enhances the longevity and efficiency of machinery. Seals are widely used in various industries, including automotive, manufacturing, and aerospace, among others.

Specifications of the 35% 2047 7 Oil Seal

The nomenclature 35% 2047 7 refers to specific dimensional and material properties associated with this oil seal. Typically, 35% indicates the sealing performance level or the degree of resistance the seal can provide against specific fluids. The 2047 may denote the specific design or profile of the seal, which might vary depending on the precision requirements of the application. 7 could refer to the thickness or cross-sectional design of the seal, which greatly influences its performance under various operational conditions.

Material Composition

Oil seals can be made from various materials, including rubber, silicone, polyurethane, and more. The materials used in the construction of the 35% 2047 7 oil seal are crucial in determining its chemical resistance, temperature tolerance, and overall durability. Generally, these seals are made from elastomeric materials that provide excellent flexibility and sealing capabilities. Common materials include

1. Nitrile Rubber (NBR) Offers good resistance to petroleum-based oils and is suitable for a wide range of applications. 2. Fluoroelastomer (FKM) Provides superior resistance to heat, chemicals, and ozone, making it ideal for high-performance environments.

3. Polyurethane (PU) Known for its abrasion resistance and flexibility, PU seals are commonly used in demanding environments.

35 47 7 oil seal

The choice of material is critical and must align with the specific application needs, including exposure to certain chemicals, temperature ranges, and mechanical loads.

Applications of the 35% 2047 7 Oil Seal

The 35% 2047 7 oil seal finds applications in diverse settings, highlighting its versatility. Some notable applications include

1. Automotive Industry These seals are commonly employed in engines, gearboxes, and differentials, where they prevent oil leaks and protect the mechanisms from contaminants.

2. Heavy Machinery In construction and agricultural equipment, oil seals play a significant role in maintaining hydraulic systems and other vital components, ensuring smooth operation under rigorous conditions.

3. Industrial Equipment Pumps, compressors, and rotating machinery use oil seals to maintain necessary lubrication levels and prevent failures caused by contamination or leakage.

4. Aerospace In critical applications such as aerospace engines and hydraulic systems, the integrity of the oil seal is paramount for safety and performance.

Conclusion

The 35% 2047 7 oil seal is an essential component that ensures the efficiency and longevity of various machinery and equipment. Understanding its construction, specifications, and applications allows industry professionals to select the right seal for their needs. Proper installation and regular maintenance of oil seals can greatly enhance the operational reliability of machinery, reducing downtime and maintenance costs. As technology advances, the design and materials of oil seals will continue to evolve, further refining their effectiveness across multiple applications. Whether in automotive, industrial, or aerospace settings, the significance of oil seals like the 35% 2047 7 cannot be overstated, making them a key player in the field of engineering and maintenance.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories