Feb . 16, 2025 10:53 Back to list

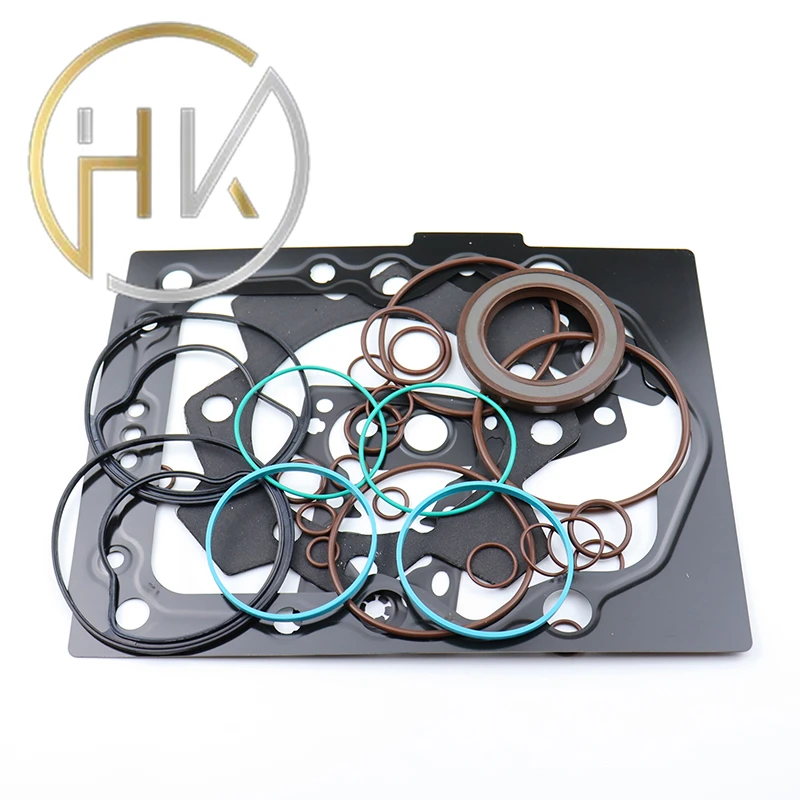

Standard Hydraulic DKB Type Dustproof Wiper Oil Seal

When it comes to maintaining the efficiency and longevity of hydraulic systems, the role of hydraulic cylinder seal kits cannot be overstated. Whether used in manufacturing industries, construction, or heavy machinery, these kits are vital in preventing fluid leakage and ensuring proper system functions. Choosing the right supplier for these seal kits is a critical decision that influences system performance and operational reliability.

5. Warranty and After-Sales Service Trustworthy suppliers stand behind their products with solid warranties. This reflects their confidence in the durability and performance of their seal kits. Additionally, responsive after-sales service ensures that any problems encountered are promptly addressed. Real-World User Experience Experienced industry professionals often report a noticeable difference after switching to a high-caliber hydraulic cylinder seal kit supplier. A heavy machinery operator noted reduced leakage and increased pressure stability after using kits from a supplier renowned for their meticulous engineering and robust testing processes. This not only extended their equipment’s lifecycle but also improved overall productivity, proving that the right supplier can have substantial operational impacts. Authoritative Insights in Selection Selecting a supplier hinges on comprehensive research and user reviews. Authoritative industry publications and professional forums often highlight suppliers who consistently garner positive feedback. Such endorsements are crucial indicators of reliability and quality. Establishing Trustworthiness A trustworthy supplier maintains transparency in pricing, materials used, and order turnaround times. Companies that engage openly on platforms like LinkedIn, responding to customer queries and participating in discussions about industry advancements, further establish their credibility and commitment to client satisfaction. Ultimately, choosing the right hydraulic cylinder seal kits supplier involves a balance of quality, service, and reliability. By assessing potential suppliers against these rigorous criteria, businesses can ensure the optimal functionality of their hydraulic systems, leading to sustained operation success and safety.

5. Warranty and After-Sales Service Trustworthy suppliers stand behind their products with solid warranties. This reflects their confidence in the durability and performance of their seal kits. Additionally, responsive after-sales service ensures that any problems encountered are promptly addressed. Real-World User Experience Experienced industry professionals often report a noticeable difference after switching to a high-caliber hydraulic cylinder seal kit supplier. A heavy machinery operator noted reduced leakage and increased pressure stability after using kits from a supplier renowned for their meticulous engineering and robust testing processes. This not only extended their equipment’s lifecycle but also improved overall productivity, proving that the right supplier can have substantial operational impacts. Authoritative Insights in Selection Selecting a supplier hinges on comprehensive research and user reviews. Authoritative industry publications and professional forums often highlight suppliers who consistently garner positive feedback. Such endorsements are crucial indicators of reliability and quality. Establishing Trustworthiness A trustworthy supplier maintains transparency in pricing, materials used, and order turnaround times. Companies that engage openly on platforms like LinkedIn, responding to customer queries and participating in discussions about industry advancements, further establish their credibility and commitment to client satisfaction. Ultimately, choosing the right hydraulic cylinder seal kits supplier involves a balance of quality, service, and reliability. By assessing potential suppliers against these rigorous criteria, businesses can ensure the optimal functionality of their hydraulic systems, leading to sustained operation success and safety.

Latest news

-

Wiper Oil Seal: Our Commitment to Clean Hydraulics

NewsAug.13,2025

-

Hydraulic Oil Seal for Self Discharging Cars

NewsAug.13,2025

-

Hub Oil Seal for Agricultural Tractor Hubs

NewsAug.13,2025

-

Skeleton Oil Seal with NBR Material

NewsAug.13,2025

-

Rotary Lip Seal for High Pressure Applications

NewsAug.13,2025

-

Cylinder Seal Kits Our Legacy of Hydraulic Trust

NewsAug.13,2025

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

Products categories