Oct . 11, 2024 01:52 Back to list

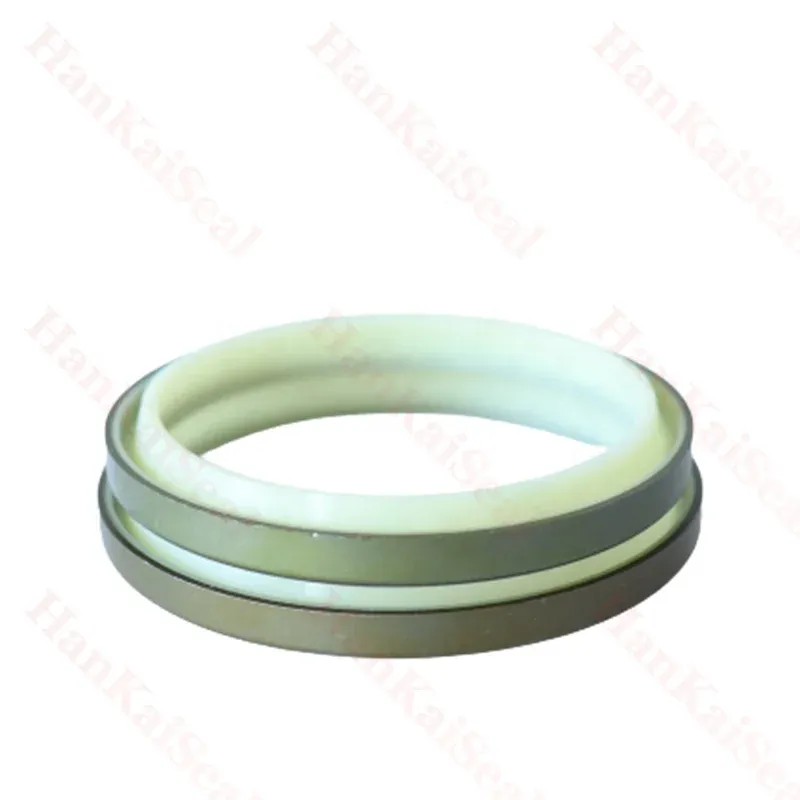

cylinder wiper

The Significance of Cylinder Wipers in Industrial Applications

In the realm of industrial automation and machinery, cylinder wipers play a pivotal role in ensuring the efficient and reliable operation of hydraulic and pneumatic cylinders. These components are integral to countless applications, ranging from manufacturing equipment to construction machinery. Understanding their design, functionality, and maintenance is crucial for engineers and technicians in various industries.

What are Cylinder Wipers?

Cylinder wipers, often referred to as rod wipers, are sealing components fitted at the cylinder's outer end. Their primary function is to prevent contaminants such as dirt, dust, and moisture from entering the cylinder while simultaneously allowing for the smooth operation of the cylinder rod. A well-designed wiper enhances the longevity and performance of hydraulic and pneumatic systems, minimizing the risk of damage to internal seals and components.

Types of Cylinder Wipers

Cylinder wipers come in various designs and materials, tailored to suit specific applications. Common types include

1. Rubber Wipers These are often made from various grades of rubber and are ideal for environments where flexibility and elasticity are required. They are effective in creating a tight seal against contaminants.

2. Polyurethane Wipers Known for their durability and resistance to abrasion, polyurethane wipers excel in severe working conditions, such as high pressure and extreme temperatures. Their longer lifespan makes them a preferred choice in numerous industrial applications.

3. Metal Wipers In environments where resistance to high pressure and wear is critical, metal wipers may be employed. They provide robust protection but may lack the flexibility of rubber or polyurethane wipers.

4. Specialty Wipers Some applications require customized wipers designed for specific environments, such as those involving chemicals or extreme temperatures. These wipers are engineered to withstand harsh conditions while ensuring optimal performance.

Importance of Cylinder Wipers

The importance of cylinder wipers cannot be overstated

. They serve as the first line of defense against contaminants that could jeopardize the functionality of hydraulic and pneumatic systems. Here are several reasons highlighting their significancecylinder wiper

1. Preventing Contaminant Entry Contaminants can cause premature wear and tear on seals and components within the cylinder. Effective wipers minimize the risk of harmful particles entering the system, thereby extending the life of the cylinder.

2. Improving Reliability With a proper sealing mechanism in place, the overall reliability of the machinery improves. This reduces downtime associated with maintenance and repairs, leading to increased productivity.

3. Enhancing Performance Well-functioning cylinder wipers contribute to smoother operation by maintaining the integrity of the cylinder. This results in consistent performance, which is vital in high-stakes manufacturing environments.

4. Cost-Effectiveness By reducing wear on internal components and minimizing the need for repairs, cylinder wipers contribute to cost savings in the long run. Investing in quality wipers can yield significant returns through enhanced machine longevity and performance.

Maintenance of Cylinder Wipers

To ensure the optimal functionality of cylinder wipers, regular maintenance is essential. This includes

- Routine Inspections Regularly checking the wipers for signs of wear or damage can prevent larger issues down the line. Inspect for cracks, tears, or deformities that may compromise performance.

- Cleaning Keeping the cylinder area clean is crucial. This helps minimize dirt accumulation that could penetrate the cylinder when the rod is in motion.

- Replacement Depending on the application and material used, wipers may need to be replaced periodically. Understanding the expected lifespan of a specific wiper type is essential for maintaining operational efficiency.

Conclusion

Cylinder wipers are simple yet vital components in the machinery and automation landscape. By preventing contaminants from entering hydraulic and pneumatic systems, they play a crucial role in maintaining machinery efficiency and longevity. For engineers, technicians, and industrial operators, understanding the significance, types, and maintenance of cylinder wipers can lead to better decision-making and improved machinery performance. In an age where operational efficiency is paramount, investing in reliable cylinder wipers is not just an option—it's a necessity.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories