Peb . 18, 2025 05:29 Back to list

replacing wiper seal on hydraulic cylinder

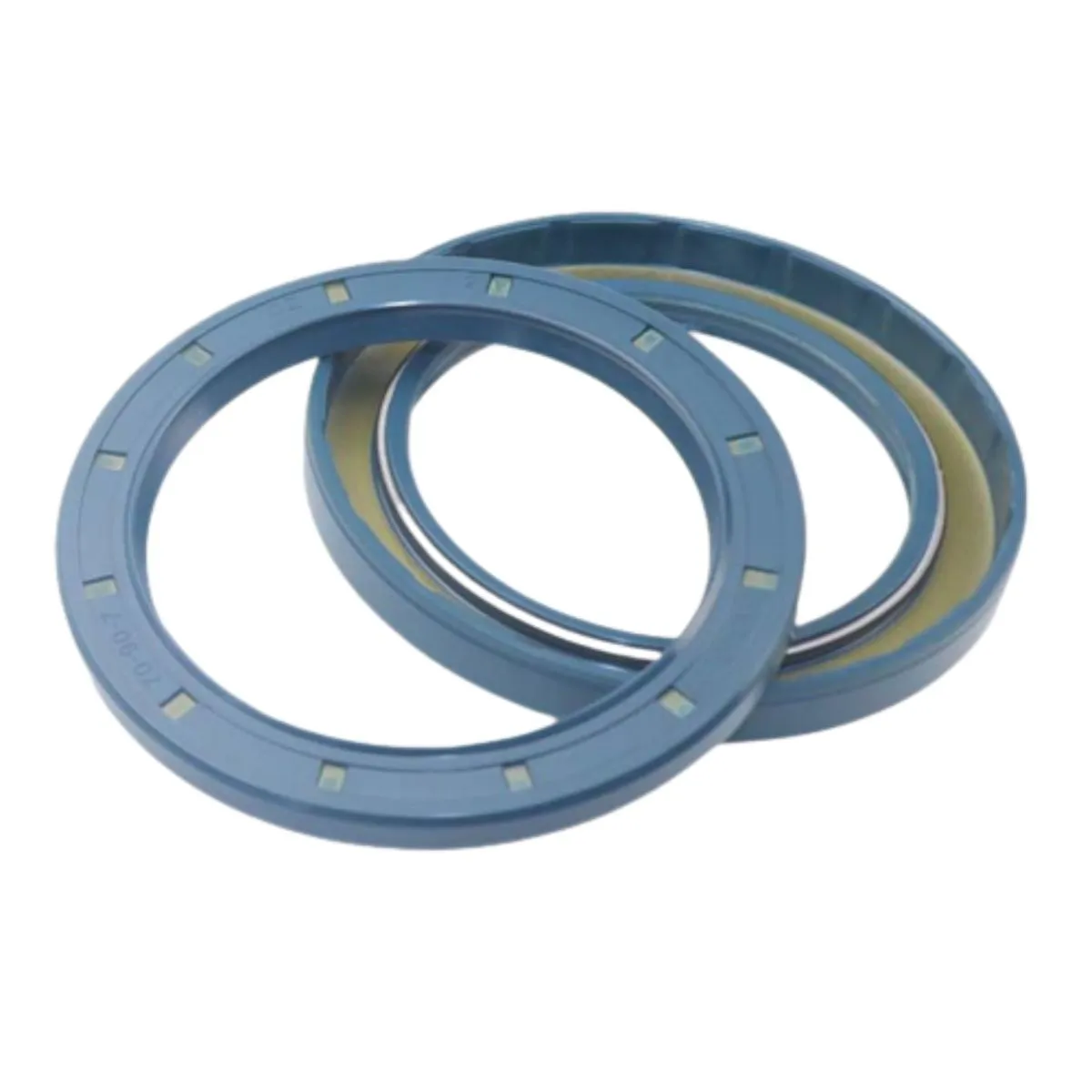

2. Access the Wiper Seal This usually involves removing protective covers and disconnecting any adjacent components obstructing access to the seal. Keep all removed parts in sequence for easier reassembly. 3. Seal Removal Carefully extract the worn seal using the appropriate tools to avoid damaging the surrounding area. Some seals require specific extraction tools provided by the manufacturer. 4. Inspection and Cleaning Inspect the seal groove and adjacent parts for damage or excessive wear. Clean the area with a lint-free cloth and appropriate cleaning solution to remove any residual contaminants. 5. Install the New Seal Lubricate the new seal lightly to facilitate insertion. Follow the manufacturer’s instructions to position the seal correctly, ensuring it sits snugly within the groove. 6. Reassemble the Components Carefully reattach all previously removed parts, ensuring each is secured and aligned properly to prevent operational issues. 7. Testing Gradually re-pressurize the system and perform initial operations to ensure the new wiper seal is functioning correctly without leaks or unusual noises. Trust and Reliability Performing regular maintenance such as wiper seal replacement not only ensures the reliability of hydraulic machinery but also builds trust in operational consistency. As professionals in the field, acknowledging the nuances of this process showcases expertise and reinforces authority on best maintenance practices. Users can rely on well-maintained equipment to deliver predictable performance, thereby reducing downtime and associated costs. For organizations and technicians, investing in the right tools, following precision guidelines, and using quality replacement components are crucial for maximizing machinery lifespan and efficiency. These deliberate efforts reflect a commitment to excellence and reliability in an ever-demanding industrial landscape.

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

-

Unleash the Power of Your Hydraulic Systems with Our Premium Seal Kits

NewsAug.06,2025

-

Specialized Hydraulic Seal Kits for Breakers, Pistons, and Presses

NewsAug.06,2025

-

Revitalize Hydraulic Systems with Premium Repair and Seal Kits

NewsAug.06,2025

-

Fortify Your Cylinders with Premium Sealing Solutions

NewsAug.06,2025

-

Elevate Hydraulic System Reliability with Specialized Seal Kits

NewsAug.06,2025

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

Products categories