Dis . 16, 2024 11:22 Back to list

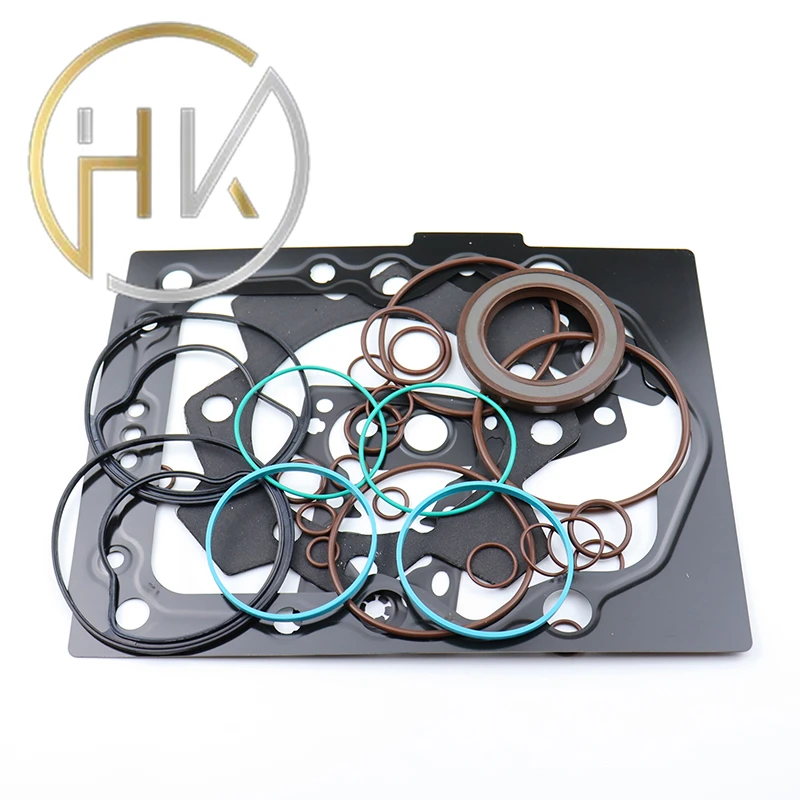

hyd cylinder seals

Understanding Hydraulic Cylinder Seals Essential Components in Fluid Power Systems

Hydraulic systems are integral to numerous industrial applications, providing a reliable and efficient method of power transmission. At the heart of these systems are hydraulic cylinders, which convert fluid power into mechanical energy. A critical component of hydraulic cylinders is the seals, which play a vital role in maintaining system efficiency, preventing fluid leakage, and ensuring the longevity of equipment. This article delves into the functions, types, and maintenance of hydraulic cylinder seals, underscoring their significance in fluid power systems.

The Importance of Seals in Hydraulic Cylinders

Hydraulic cylinder seals are designed to create a barrier that prevents hydraulic fluid from leaking out of the cylinder while also stopping contaminants from entering the system. Proper sealing is essential for maintaining pressure within the cylinder, which enables the efficient functioning of hydraulic actuators. Any failure in the sealing components can result in reduced performance, fluid losses, and potential damage to the cylinder and associated machinery.

Seals also serve an essential function in controlling the movement of the piston within the cylinder. They ensure that the hydraulic pressure exerted on one side of the piston effectively translates into the desired mechanical movement on the other side. Consequently, seals contribute significantly to the overall performance, reliability, and safety of hydraulic systems.

Types of Hydraulic Cylinder Seals

There are several types of seals employed in hydraulic cylinders, each designed for specific purposes and conditions

1. Static Seals These seals are used in applications where there is no relative motion between the two surfaces. Common examples include O-rings and gaskets, which help seal components such as end caps and cylinder housings.

2. Dynamic Seals Unlike static seals, dynamic seals are designed to accommodate relative movement between surfaces. These include piston seals, rod seals, and wiper seals. Piston seals are placed around the piston itself, preventing fluid from leaking and ensuring efficient operation. Rod seals, on the other hand, seal the area where the rod extends from the cylinder, preventing fluid loss and contamination ingress. Wiper seals help remove dirt and debris from the rod before it enters the cylinder, protecting the internal components from wear.

3. Backup Rings Often used in conjunction with O-rings, backup rings provide extra support to prevent the O-ring from extruding into the clearance gaps, especially in high-pressure applications. They help maintain the integrity of the seal under challenging operating conditions.

4. Slip Rings Used in situations where the seal must accommodate rotary motion, slip rings provide a means of sealing while allowing for rotational movement, commonly found in hydraulic motors and similar applications.

Material Considerations

hyd cylinder seals

The choice of material for hydraulic seals is crucial, as it impacts the seal's performance, durability, and suitability for various fluids. Common materials include

- Nitrile Rubber (NBR) Suitable for many applications due to its excellent resistance to petroleum-based fluids. - Fluoroelastomers (FKM) Known for their high-temperature resistance and compatibility with aggressive fluids, making them ideal for demanding environments. - Polyurethane Provides excellent wear resistance and is often used for dynamic seals in hydraulic applications. - PTFE (Polytetrafluoroethylene) Known for its low friction properties, PTFE seals are commonly used in high-performance hydraulic applications.

Maintenance and Care

To ensure the longevity and proper functioning of hydraulic cylinder seals, regular maintenance is essential. Here are some important maintenance tips

1. Routine Inspections Regularly check seals for signs of wear, damage, or degradation. Early detection can prevent major failures and costly repairs.

2. Cleanliness Keep the hydraulic system clean. Debris and contaminants can damage seals and compromise their effectiveness, leading to leakage and system failures.

3. Proper Installation Ensure that seals are installed correctly according to the manufacturer's specifications. Incorrect installation can lead to premature failures.

4. Monitor Fluid Quality The quality of hydraulic fluid directly affects seal performance. Regular fluid analysis can help identify potential issues before they escalate.

5. Avoid Overpressure Always operate hydraulic systems within the recommended pressure limits to prevent undue stress on seals.

Conclusion

Hydraulic cylinder seals are indispensable components that ensure the efficiency, safety, and reliability of hydraulic systems. Understanding the types of seals, materials used, and maintenance practices can help users enhance the performance of their hydraulic cylinders. As industries continue to rely on hydraulic technology for various applications, appreciating the role of seals in these systems becomes increasingly vital. By prioritizing seal maintenance and selection, businesses can ensure optimal performance and longevity of their hydraulic equipment, ultimately leading to increased productivity and reduced operational costs.

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

-

Unleash the Power of Your Hydraulic Systems with Our Premium Seal Kits

NewsAug.06,2025

-

Specialized Hydraulic Seal Kits for Breakers, Pistons, and Presses

NewsAug.06,2025

-

Revitalize Hydraulic Systems with Premium Repair and Seal Kits

NewsAug.06,2025

-

Fortify Your Cylinders with Premium Sealing Solutions

NewsAug.06,2025

-

Elevate Hydraulic System Reliability with Specialized Seal Kits

NewsAug.06,2025

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

Products categories