jan . 24, 2025 05:35 Back to list

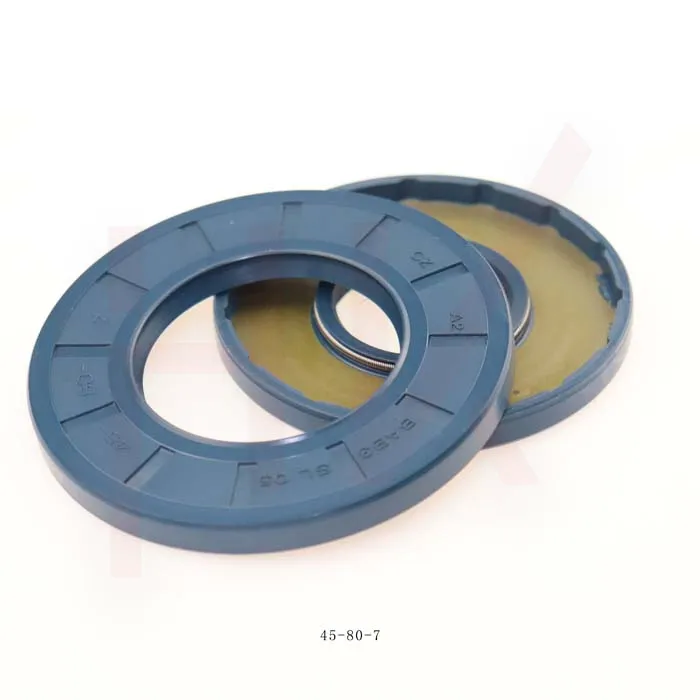

170×190×13 Tcv Oil Seal High Pressure Oil Seal Hydraulic Pump Seal

In considering the authoritativeness of seal kit information, turning to industry experts and peer-reviewed studies offers valuable insights. Publications from authoritative bodies and journals provide deeper understanding, helping individuals make informed decisions about seal kit investments. Moreover, collaborative workshops and conferences often serve as platforms for sharing advanced research findings and technological developments concerning seal and pump optimization. Establishing a robust troubleshooting protocol is another layer in ensuring reliability. Consulting installation and troubleshooting guides, often available from seal kit manufacturers, empowers technical teams to address issues swiftly. Training programs also enhance the comprehension of proper seal installation and maintenance procedures, thereby maximizing the utility and lifespan of purchased kits. Trustworthiness in the context of seal kits is cultivated through transparency. Suppliers who openly share product specifications, testing outcomes, and quality standards build stronger consumer relationships. Furthermore, insightful customer reviews and case studies provide real-world perspectives, demonstrating a product's effectiveness across varying applications. Advancements in manufacturing technology continue to influence seal kit innovation. Automation, AI-driven testing, and sustainable material sourcing are becoming increasingly prevalent, enhancing the precision and environmental consciousness of seal production. As these technologies evolve, the future promises seal kits that offer greater resilience, longevity, and eco-friendliness. Ultimately, businesses prioritizing high-quality seal kits for their pumps not only ensure smoother operational continuity but also experience significant cost savings over time. Expertly crafted seal kits affirm a company's dedication to maintaining efficient, reliable pump systems, underscoring the critical role these components play in industrial applications.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories