okt . 31, 2024 01:19 Back to list

hydraulic cylinder repair kits

Understanding Hydraulic Cylinder Repair Kits A Comprehensive Guide

Hydraulic cylinders are integral components in various industrial applications, providing the force necessary to lift, tilt, and move heavy loads. However, like any mechanical device, they are prone to wear and damage over time. When this occurs, hydraulic cylinder repair kits become essential. In this article, we will explore the importance of these kits, what they typically contain, and how to use them for effective maintenance of hydraulic cylinders.

Importance of Hydraulic Cylinder Repair Kits

Hydraulic systems are often subjected to harsh operating conditions, which can lead to leaks, loss of pressure, and other malfunctions. When a hydraulic cylinder fails, it can result in decreased efficiency, increased downtime, and costly repairs. Utilizing repair kits can significantly extend the life of hydraulic cylinders and reduce the need for complete replacements. These kits are designed to restore the functionality of cylinders quickly, ensuring that operations can continue with minimal disruption.

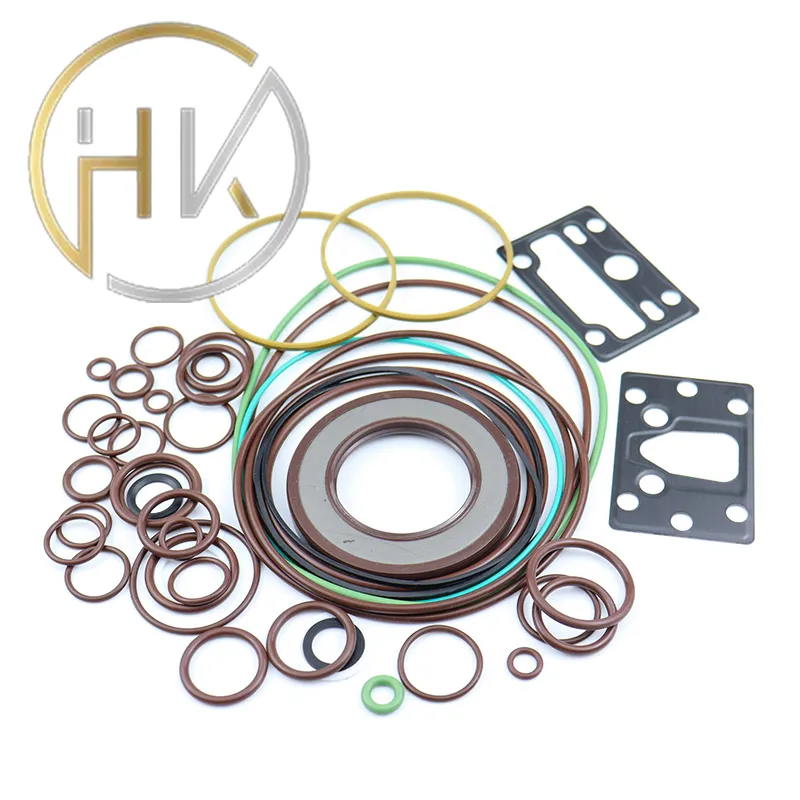

Components of a Hydraulic Cylinder Repair Kit

A typical hydraulic cylinder repair kit includes various seals, O-rings, and other necessary components that are crucial for the cylinder's operation. Here are some common elements you might find in a repair kit

1. Seals These rubber or polyurethane components prevent hydraulic fluid from leaking out of the cylinder. There are usually several types of seals, including piston seals, rod seals, and end cap seals.

2. O-Rings These circular rings are typically made from elastomeric materials and provide a tight seal between the cylinder and its components, helping to maintain pressure and prevent leakage.

3. Backup Rings These are used alongside O-rings to provide additional support, especially in high-pressure situations.

4. Dust Seals These prevent dirt and debris from entering the cylinder, which can cause significant damage over time.

5. Retaining Rings These are necessary for holding certain parts in place within the cylinder assembly.

hydraulic cylinder repair kits

6. Instruction Manual Most kits come with a detailed guide that provides step-by-step instructions on how to replace the damaged parts and reassemble the cylinder.

How to Use a Hydraulic Cylinder Repair Kit

Repairing a hydraulic cylinder using a repair kit can be a straightforward process if done correctly. Here’s a general guide to follow

1. Disassemble the Cylinder Carefully remove the hydraulic cylinder from its application. Then, disassemble it to access the internal components. Take care to remember the order of parts for reassembly.

2. Inspect the Components Check for wear and damage in the cylinder bore, piston, and rod. This step will help identify all parts that need replacement.

3. Replace Damaged Parts Remove old seals and O-rings and replace them with new ones from the repair kit. Ensure that they are seated properly to prevent leaks.

4. Reassemble the Cylinder Carefully reassemble the hydraulic cylinder, ensuring that all components are in their correct place.

5. Test the Cylinder Once assembled, reconnect the cylinder to the hydraulic system and test it under low pressure before bringing it up to full operational pressure. This will allow you to check for any leaks or issues.

Conclusion

Using hydraulic cylinder repair kits is a practical and cost-effective method for maintaining hydraulic systems. With the right tools and components, operators can restore cylinder functionality and avoid the high costs associated with complete replacements. Regular maintenance using these kits not only prolongs the life of hydraulic equipment but also ensures safety and efficiency in industrial operations. Whether you're a seasoned technician or a do-it-yourself enthusiast, understanding and utilizing hydraulic cylinder repair kits can save you time and money while keeping your machinery running smoothly.

-

Understanding Oil Seals and Their Role in Machinery Efficiency

NewsApr.08,2025

-

The Importance of Seals in Agricultural and Hydraulic Systems

NewsApr.08,2025

-

Essential Guide to Seal Kits for Efficient Machinery Maintenance

NewsApr.08,2025

-

Choosing the Right TCV Oil Seal for Your Machinery

NewsApr.08,2025

-

Choosing the Right Hydraulic Oil Seals for Reliable Performance

NewsApr.08,2025

-

A Comprehensive Guide to Oil Seals and Their Applications

NewsApr.08,2025

-

The Importance of High-Quality Oil Seals in Industrial Applications

NewsMar.26,2025

Products categories