nov . 22, 2024 18:15 Back to list

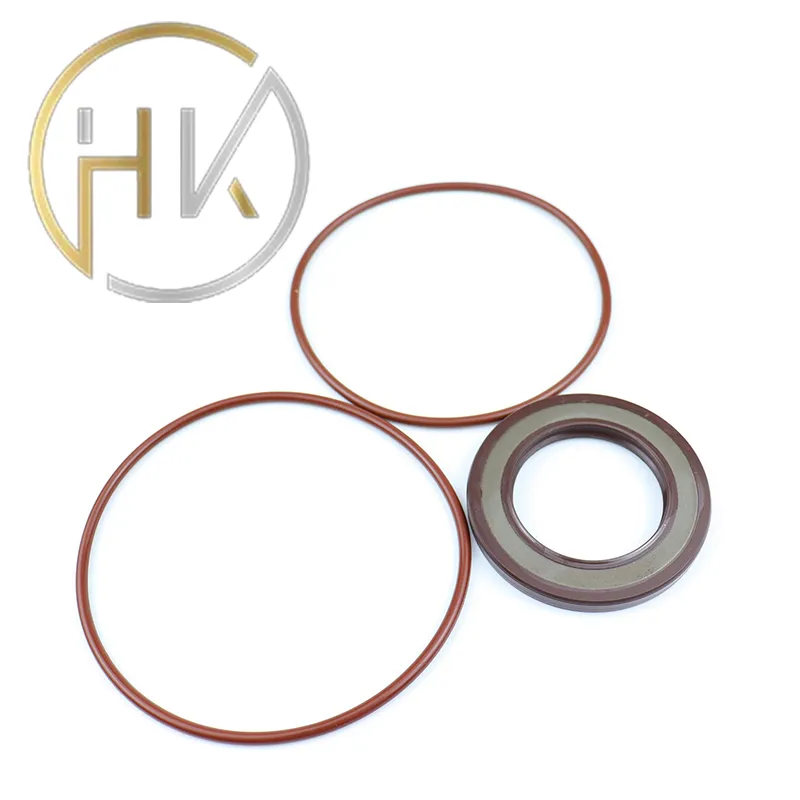

cfw oil seal

Understanding CFW Oil Seals Importance and Applications

In machinery and automotive engineering, the components that maintain the efficiency and longevity of systems are critical. One such essential component is the oil seal, specifically the CFW (Composite Fabricated Wheel) oil seal. This versatile sealing solution plays a vital role in preventing lubricant leaks and protecting against contamination, ensuring smooth operation in various applications.

What is a CFW Oil Seal?

CFW oil seals are designed to seal the space between moving and stationary parts, primarily to retain oil and lubricants within a system. Typically made from materials such as rubber, polyurethane, or composite materials, CFW oil seals are engineered to withstand extreme environmental conditions, including temperature fluctuations, pressure changes, and exposure to chemicals. Their distinctive design often incorporates a lip that rubs against a shaft to create a barrier, preventing the escape of lubricants while keeping contaminants at bay.

Importance of CFW Oil Seals

The effectiveness of CFW oil seals is paramount for several reasons. First, they significantly enhance the operational efficiency of machinery. By retaining the oil within systems, they minimize friction between moving parts, which can lead to wear and tear if left unsealed. This, in turn, translates into longer equipment life, reduced maintenance costs, and less downtime in industrial settings.

Moreover, CFW oil seals help maintain the integrity of mechanical systems. By preventing contaminants such as dirt, dust, and water from entering the oil reservoir, they ensure that the lubricants remain clean and effective. This is especially crucial in environments where machinery is exposed to harsh conditions, such as construction sites or factories, where debris can cause significant damage.

Applications of CFW Oil Seals

cfw oil seal

CFW oil seals find applications in a variety of industries, including automotive, aerospace, marine, and manufacturing. In the automotive sector, they are used in engines, transmissions, and differentials. These seals are vital for maintaining optimal oil levels, thereby ensuring that engines operate at peak performance.

In aerospace applications, CFW oil seals are employed in landing gear and hydraulic systems, where reliability is crucial. Failure of these seals can lead to catastrophic outcomes, making their proper selection and installation essential.

Manufacturing equipment, ranging from pumps to conveyor systems, also relies on CFW oil seals. In these applications, the seals prevent lubricant leakage, maintaining the efficiency of machinery critical to production processes.

Choosing the Right CFW Oil Seal

When selecting a CFW oil seal, it is essential to consider several factors, including the operating environment, temperature, pressure, and the type of lubricant used. Different materials possess distinct properties that can either enhance or limit their effectiveness in specific situations. Thus, consulting with manufacturers or technical experts can lead to better decision-making and optimal performance of the equipment.

Conclusion

CFW oil seals are a cornerstone of reliable machinery operation across multiple industries. Their ability to prevent lubricant leaks and protect against contaminants makes them indispensable components that contribute to the longevity and efficiency of mechanical systems. As industries continue to prioritize reliability and performance, the importance of high-quality CFW oil seals will only grow, reinforcing their status as essential tools in modern engineering.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories