নভে. . 27, 2024 19:30 Back to list

PU Wiper Seal Benefits and Applications in Various Industries

Understanding PU Wiper Seals Design, Functionality, and Applications

In the realm of industrial engineering and manufacturing, seals play a crucial role in ensuring the integrity and longevity of machinery and equipment. Among various types of seals, Polyurethane (PU) wiper seals have gained popularity due to their superior performance and versatility. This article delves into the fundamental aspects of PU wiper seals, highlighting their design, functionality, and applications across different industries.

What are PU Wiper Seals?

PU wiper seals are specialized sealing components made from polyurethane, a polymer known for its excellent resilience, flexibility, and wear resistance. These seals are primarily designed to prevent contaminants, such as dirt, dust, and moisture, from entering critical machine components. They serve as the first line of defense in hydraulic and pneumatic applications, safeguarding internal mechanisms from external wear and tear.

Design Features

The design of PU wiper seals is essential to their effectiveness. These seals typically feature a lip design that allows them to “wipe” surfaces clean as the piston or rod moves, ensuring that no debris can infiltrate the machinery. The material’s inherent elasticity allows the wiper seals to maintain a tight contact with the surfaces they protect while also adapting to any minor imperfections in those surfaces.

Additionally, PU wiper seals can be customized in various shapes, sizes, and hardness levels to meet specific operational requirements. Whether it’s a miniaturized seal for small hydraulic cylinders or a large wiper seal for heavy machinery, the flexibility in design ensures that PU wiper seals can accommodate a wide range of industrial applications.

Functionality

The primary function of PU wiper seals is to prevent contamination. This is vital for modern machinery, where even a small amount of dirt can lead to significant operational issues and costly downtimes. The wiper action effectively removes particles from surfaces, ensuring that the seals in hydraulic or pneumatic systems do not wear out prematurely.

Furthermore, PU wiper seals exhibit excellent resistance to a variety of chemicals, oils, and temperature fluctuations, making them suitable for diverse environments. Unlike rubber seals, polyurethane provides a better performance in high-pressure situations and can endure harsher conditions without degrading.

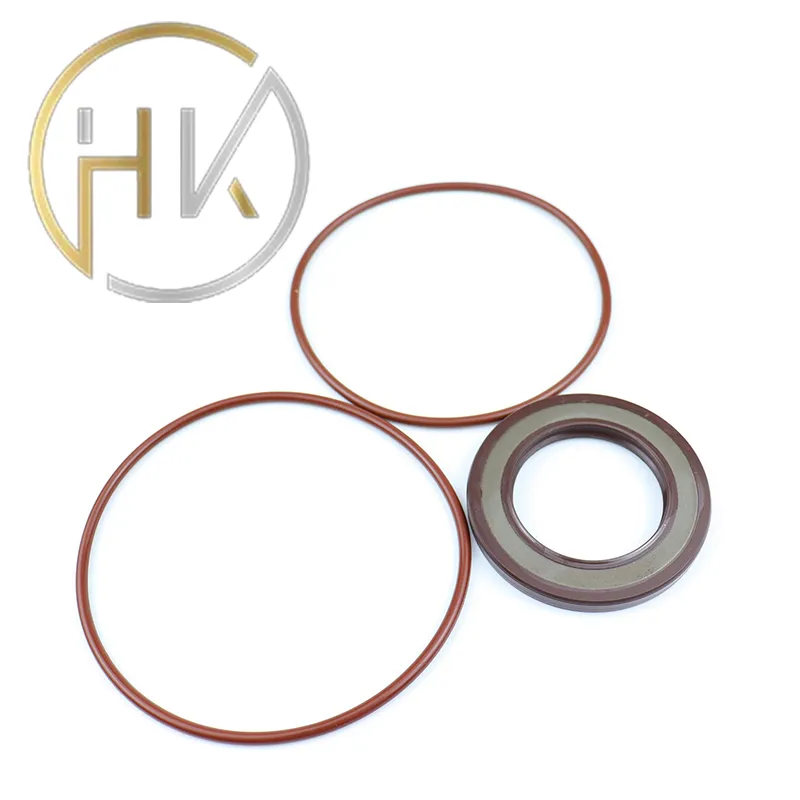

pu wiper seal

Applications

PU wiper seals are widely used across numerous industries, including

1. Hydraulics In hydraulic cylinders, these seals prevent the entry of external contaminants while allowing the hydraulic fluid to flow smoothly, enhancing system efficiency and lifespan.

2. Mining and Construction Equipment in these industries faces tough working conditions. PU wiper seals are essential for protecting machinery from dust and debris that can contribute to premature wear.

3. Automotive In vehicles, wiper seals are used in various components like shock absorbers and steering systems, where they provide essential protection against environmental elements.

4. Agricultural Machinery Given the outdoor working conditions, equipment used in agriculture heavily relies on PU wiper seals to ensure operational reliability and minimize maintenance needs.

5. Aerospace With stringent safety standards, the aerospace industry utilizes PU wiper seals to protect sensitive components from contamination while maintaining performance under high pressures and temperatures.

Conclusion

In summary, PU wiper seals are indispensable components in various industrial applications, offering excellent protection against contaminants, wear, and harsh environments. Their unique design and material properties ensure that they perform effectively in challenging conditions, making them a preferred choice for engineers and manufacturers. As industries continue to evolve and demand more durable and reliable solutions, PU wiper seals will undoubtedly play a crucial role in enhancing machine efficiency and longevity.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories