ডিসে. . 02, 2024 04:31 Back to list

Similar Specifications for 20% 2035 7 Oil Seal Replacement Options Available

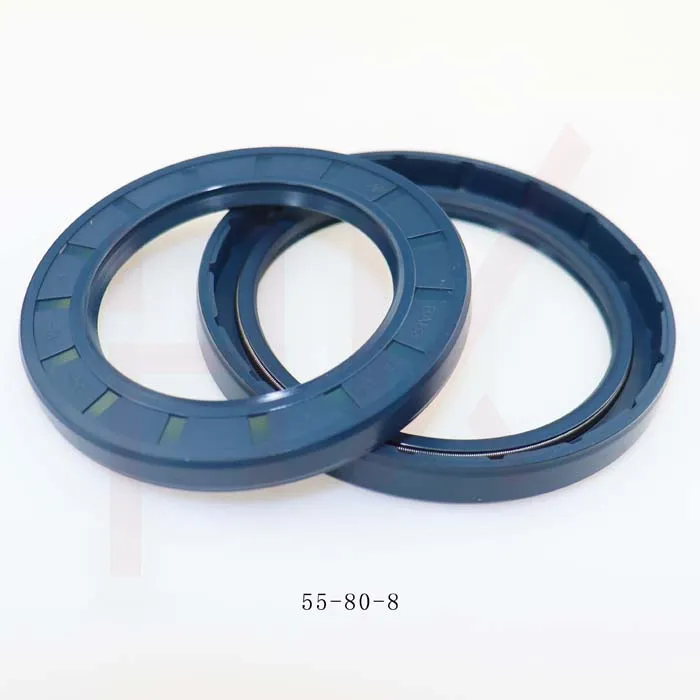

Understanding the 20% 35% 7% Oil Seal A Comprehensive Guide

In the world of machinery and engineering, oil seals play a critical role in ensuring efficient operation and longevity of various components. The 20% 35% 7% oil seal is a specific type of seal that has garnered attention due to its unique specifications and applications in various industrial settings. In this article, we will explore the significance, design, and applications of such oil seals, providing a thorough understanding of their importance in modern engineering.

What is an Oil Seal?

An oil seal, also known as a rotary shaft seal, is designed to retain lubricants (oil or grease) and prevent leakage while keeping contaminants from entering the machinery. Typically made of rubber, PTFE (Polytetrafluoroethylene), or a combination of polymer materials, oil seals are essential components in machinery that has rotating parts. They come in various shapes and sizes, and their design often features a lip that creates a tight seal against the rotating shaft.

The 20% 35% 7% Specification

The 20% 35% 7% designation relates to the composition of materials and the design characteristics that define this particular oil seal. Understanding these percentages aids in determining its capabilities

1. 20% - Material Composition This percentage often refers to the amount of a specific filler or additive in the rubber. This could involve reinforcements for added strength or chemical resistance capabilities, essential for applications involving exposure to harsh environments.

2. 35% - Hardness Level The 35% can refer to the hardness of the material, which is crucial for determining flexibility and wear resistance. Oil seals that are too soft may deform under pressure, while those that are too hard may crack or fail to conform to the shaft properly. A 35% hardness level suggests a balanced design, focusing on durability while maintaining enough flexibility to adapt to slight variations in shaft movement.

3. 7% - Elasticity and Compression Set This percentage typically indicates the elasticity of the material. A seal needs to compress effectively to create a proper seal but should also retain its shape after being subjected to mechanical forces. Here, the 7% suggests a design optimized for maintaining sealing capabilities under various operational conditions.

Key Features and Benefits

20 35 7 oil seal

The 20% 35% 7% oil seal comes with several advantages that contribute to its growing popularity in various industries

- Enhanced Sealing Performance The careful balance of materials, along with design specifications, contributes to a seal that performs excellently in preventing leaks and contamination. This aspect is especially crucial in hydraulic systems, automotive applications, and manufacturing equipment where fluid integrity is paramount.

- Durability The right composition can yield an oil seal that withstands extreme temperatures, aggressive chemicals, and abrasion. This durability translates to reduced maintenance costs and longer service intervals, maximizing efficiency in operations.

- Versatility Oil seals of this specification can find applications across various sectors, including automotive, aerospace, marine, and industrial machinery. Whether in engines, gearboxes, or hydraulic systems, a well-designed oil seal adapts to the unique demands of each environment.

Applications

industries often rely on the 20% 35% 7% oil seal for critical applications. In automotive manufacturing, for example, these seals maintain smooth operations of engines and drivetrains, preventing the loss of lubricants which could lead to severe machinery damage. In hydraulic systems, they ensure that fluids remain contained, promoting efficient power transfer and system performance.

Moreover, with the rise of electric vehicles and advanced machinery, the demand for reliable oil seals is expected to grow, highlighting the importance of innovative designs like the 20% 35% 7% oil seal.

Conclusion

In summary, the 20% 35% 7% oil seal exemplifies an intersection of material science and engineering design that caters to the rigorous demands of modern applications. Understanding its composition and functionality provides insights not only into sealing technology but also into broader engineering principles critical for maintaining machinery efficiency. As industries continue to evolve, the importance of optimizing components like oil seals becomes ever more significant, underlining their role in driving operational success.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories