дек. . 10, 2024 07:03 Back to list

hydraulic cylinder seal kits by size

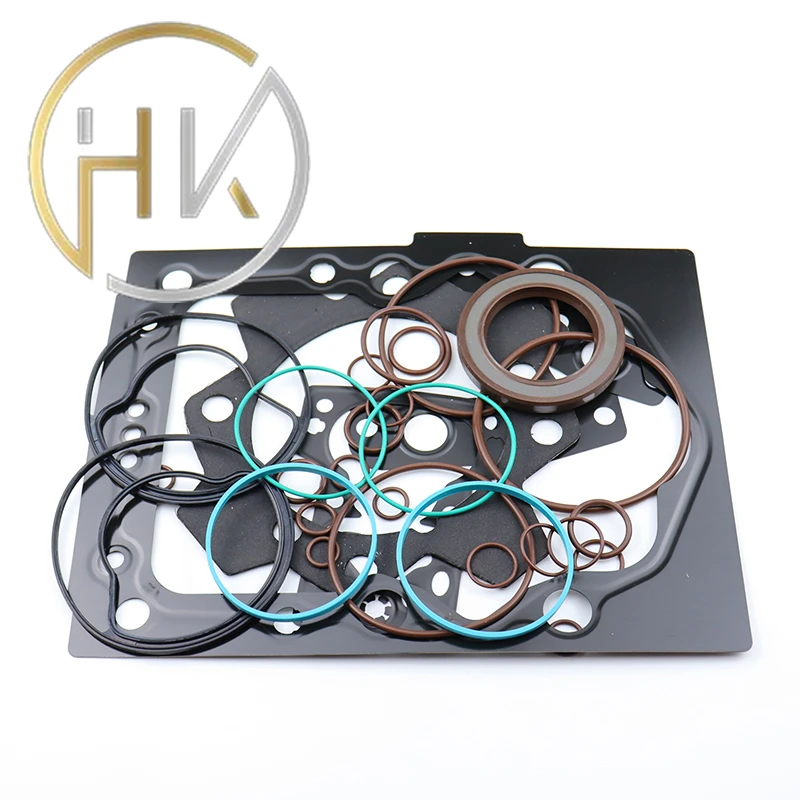

Hydraulic Cylinder Seal Kits by Size A Comprehensive Guide

Hydraulic systems are integral to various industries, powering machinery ranging from construction equipment to manufacturing tools. A crucial component within these systems is the hydraulic cylinder, which relies on seals to maintain efficiency and prevent leaks. Over time, these seals wear out and require replacement, making seal kits invaluable for maintenance and repair. This article delves into hydraulic cylinder seal kits by size, highlighting their importance and guiding users on selecting the right kits for their needs.

Understanding Hydraulic Cylinder Seals

Hydraulic cylinders convert hydraulic energy into mechanical energy, providing force to perform various tasks. They operate under high pressure, which places significant stress on the seals. These seals are designed to prevent hydraulic fluid from leaking out of the cylinder, ensuring that the cylinder can maintain pressure. The effectiveness of a hydraulic system largely depends on the quality and appropriateness of its seals.

Seals are typically made from various materials, including polyurethane, rubber, and PTFE. Each material has its specific properties suited for different applications. However, the size of the seals is equally critical. If seals are too small, they may not be able to withstand the pressure, leading to leaks and system failures. Conversely, seals that are too large can cause friction and wear on the cylinder walls, reducing efficiency.

The Importance of Size in Seal Kits

When it comes to selecting hydraulic cylinder seal kits, size is paramount. Seal kits are generally categorized by the specific dimensions of the cylinders they are designed to fit. The most common measurements include the diameter of the cylinder, the stroke length, and the width of the seals. It’s essential for users to accurately measure these dimensions to ensure compatibility.

1. Diameter The outer and inner diameters of the cylinder dictate the size of the seals required. Incorrect measurements can lead to inadequate sealing, which can result in costly downtime and repairs.

2. Stroke Length The stroke length will determine how much the seal needs to accommodate the movement of the piston within the cylinder. A seal that cannot extend or compress adequately may fail, leading to leaks.

3. Width of the Seals The width of the seals plays a critical role in ensuring that the seals fit snugly within their grooves. This is vital for preventing any hydraulic fluid from escaping.

hydraulic cylinder seal kits by size

Selecting the Right Seal Kit

When choosing a hydraulic cylinder seal kit based on size, follow these steps

1. Measure Accurately Utilize calipers or micrometers to obtain precise measurements of the cylinder. Measure the outer and inner diameters, as well as the depth of the seal grooves.

2. Consult Manufacturer Specifications Always refer to the hydraulic cylinder’s manufacturer specifications. Most manufacturers provide detailed diagrams and dimensions, ensuring that you select the correct kit.

3. Consider Material Types Depending on the operating conditions (temperature, pressure, and fluid type), select the right material for the seals. For example, if the application involves high temperatures, opt for seals made from high-performance materials like PTFE.

4. Check Compatibility Ensure that the seal kit is compatible with your hydraulic system. Some kits may be designed for specific models or brands, so verify before purchasing.

5. Review Quality and Ratings Opt for seal kits from reputable manufacturers, and check customer reviews and ratings. Quality seals will last longer, reducing maintenance frequency and costs over time.

Conclusion

Hydraulic cylinder seal kits are essential for the smooth operation of hydraulic systems, and selecting the right kit based on size is critical. Understanding the dimensions and properties of seals enables users to maintain their equipment effectively, prolonging its lifespan and ensuring optimal performance. By following best practices when selecting seal kits and prioritizing accurate measurements, operators can minimize downtime and enhance the efficiency of their hydraulic systems. In an industry where precision and reliability are paramount, the importance of quality seal kits cannot be overstated.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories