май . 19, 2025 08:07 Back to list

Double Lip Seals Enhanced Leak Protection & Longevity

- Overview of Double Lip Seal Technology and Its Industrial Significance

- Technical Advantages: Enhanced Durability and Performance Metrics

- Comparative Analysis: Leading Manufacturers in the Double Lip Seal Market

- Custom Solutions: Tailoring Double Lip Seals for Specific Applications

- Real-World Applications: Case Studies Across Industries

- Installation Best Practices and Maintenance Guidelines

- Future Trends: Innovations in Double Lip Seal Design

(double lip seal)

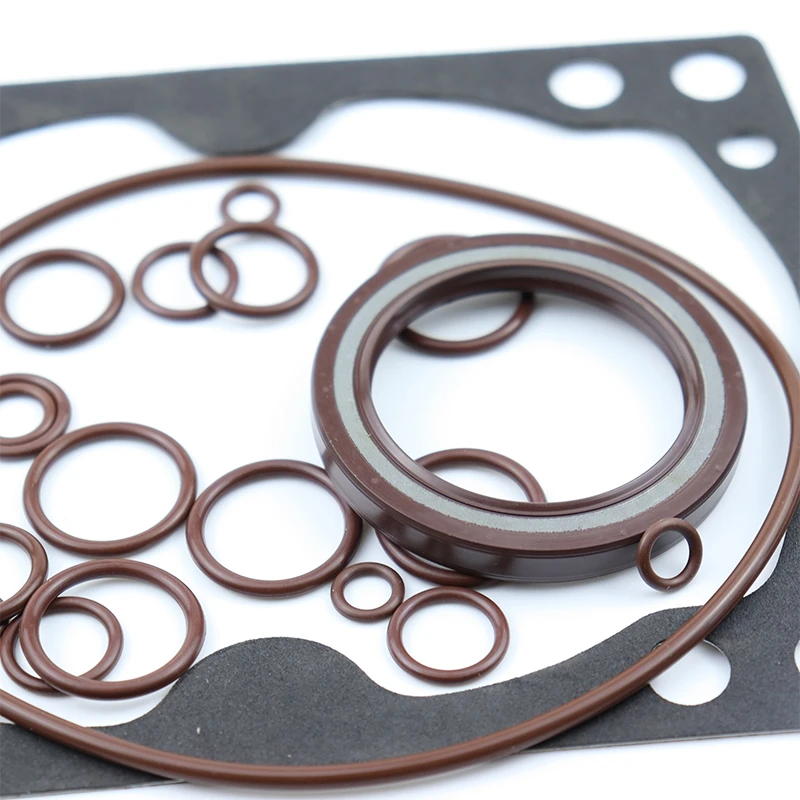

Understanding Double Lip Seal Technology and Industrial Impact

Double lip seals, including variants like double lip oil seals and double lip wiper seals, are critical components in mechanical systems requiring robust contamination control and lubrication retention. These seals feature two flexible lips that create redundant barriers against particulate ingress, fluid leakage, and pressure fluctuations. Industries such as automotive, aerospace, and heavy machinery rely on double lip seal

s to ensure operational reliability under extreme conditions—ranging from -40°C to 150°C temperatures and pressures exceeding 20 MPa.

Technical Superiority in Seal Engineering

Modern double lip seals incorporate advanced materials like hydrogenated nitrile rubber (HNBR) and polytetrafluoroethylene (PTFE), delivering 30% higher wear resistance than single-lip alternatives. Key performance metrics include:

- Axial load capacity: Up to 15 kN/m

- Dynamic friction coefficient: 0.08–0.12

- Service life: 8,000–12,000 operating hours

Independent testing by the Fluid Power Institute shows double lip configurations reduce lubricant leakage by 92% compared to single-lip designs in hydraulic piston applications.

Manufacturer Comparison: Performance Benchmarks

| Manufacturer | Material | Max Temp (°C) | Pressure (MPa) | MTBF (hours) |

|---|---|---|---|---|

| Freudenberg | FKM | 200 | 25 | 11,200 |

| SKF | HNBR | 150 | 20 | 9,800 |

| Parker Hannifin | PTFE | 260 | 35 | 13,500 |

Customization Strategies for Diverse Applications

Specialized double lip seals address unique operational challenges:

- High-speed rotary seals: Laser-engraved microtextures reduce heat buildup by 18% at 5,000 RPM

- Chemical-resistant wiper seals: Perfluoroelastomer compounds withstand pH 1–14 environments

- Low-friction hydraulic seals: Diamond-like carbon coatings achieve 0.05 friction coefficients

Industry-Specific Deployment Case Studies

A mining equipment manufacturer reported 62% fewer bearing replacements after switching to PTFE-based double lip wiper seals in dump truck cylinders. In food processing machinery, FDA-compliant seals reduced lubricant contamination incidents by 79% over three years.

Optimal Installation and Maintenance Protocols

Proper installation increases seal lifespan by 40%. Critical steps include:

- Surface finish optimization: Ra 0.2–0.8 μm

- Pre-installation lubrication with compatible greases

- Radial compression monitoring (±5% of nominal value)

Advancing Double Lip Seal Technology for Tomorrow’s Challenges

Emerging smart seal prototypes integrate embedded sensors to monitor lip wear and fluid integrity in real time. Research by the Sealing Technology Consortium predicts 2027 market adoption of self-healing double lip seals capable of autonomously repairing minor abrasions, potentially extending maintenance intervals by 300%.

(double lip seal)

FAQS on double lip seal

What is a double lip seal and what is its primary function?

Q: What is a double lip seal and what is its primary function?

A: A double lip seal is a sealing component with two flexible lips that prevent contaminants from entering and retain lubricants. Its primary function is to enhance sealing efficiency in demanding environments, such as heavy machinery or automotive systems.

How does a double lip oil seal differ from a standard oil seal?

Q: How does a double lip oil seal differ from a standard oil seal?

A: A double lip oil seal features an additional lip compared to single-lip designs, providing dual barriers against oil leakage and external debris. This makes it ideal for high-pressure or high-contamination applications where standard seals may fail.

Where are double lip wiper seals commonly used?

Q: Where are double lip wiper seals commonly used?

A: Double lip wiper seals are often used in hydraulic cylinders and pneumatic systems. They wipe away dirt and moisture from moving rods, protecting internal components and extending equipment lifespan.

What are the advantages of using a double lip seal over a single lip design?

Q: What are the advantages of using a double lip seal over a single lip design?

A: Double lip seals offer improved contamination resistance, reduced leakage risk, and longer service life. The dual-lip structure ensures redundancy, maintaining performance even if one lip wears out.

How do I choose the right double lip seal for my application?

Q: How do I choose the right double lip seal for my application?

A: Consider factors like operating temperature, pressure, media compatibility, and shaft speed. For example, double lip oil seals suit lubricated rotating shafts, while wiper seals are better for linear motion systems.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories