жнів . 06, 2024 13:21 Back to list

Top Lip Seal Suppliers Offering High-Quality Solutions for Diverse Industrial Applications and Needs

Understanding Lip Seal Suppliers A Key Player in Fluid Sealing Technology

In modern engineering and manufacturing, fluid sealing is a critical component that ensures the efficiency and longevity of machinery. Among the various types of sealing solutions, lip seals, also known as radial lip seals or rotary seals, are widely used. They are essential for preventing leaks in rotating shafts and protecting internal components from dust, dirt, and moisture. This article explores the role of lip seal suppliers and the factors to consider when selecting a supplier for these vital components.

The Importance of Lip Seals

Lip seals are designed to create a static or dynamic seal between two surfaces, typically where a shaft passes through a housing. Their primary function is to retain lubricants while keeping contaminants out. They consist of a flexible lip that exerts pressure against the shaft, forming a reliable barrier. As industries across the globe continue to advance, the demand for high-performance lip seals has surged, making the role of suppliers paramount in ensuring the availability of high-quality products.

The Role of Lip Seal Suppliers

Lip seal suppliers play a crucial role in the supply chain of mechanical components. They are responsible for sourcing, manufacturing, and distributing lip seals to various industries, including automotive, aerospace, manufacturing, and consumer goods. A reputable supplier not only provides a range of lip seal options but also offers technical support and expertise in selecting the right seals for specific applications.

Factors to Consider When Choosing a Lip Seal Supplier

1. Quality and Compliance When it comes to sealing solutions, quality is non-negotiable. Suppliers should adhere to industry standards and certifications, such as ISO 9001, to ensure consistent quality in their products. This is crucial for applications that operate under extreme conditions, where a reliable seal can prevent costly failures.

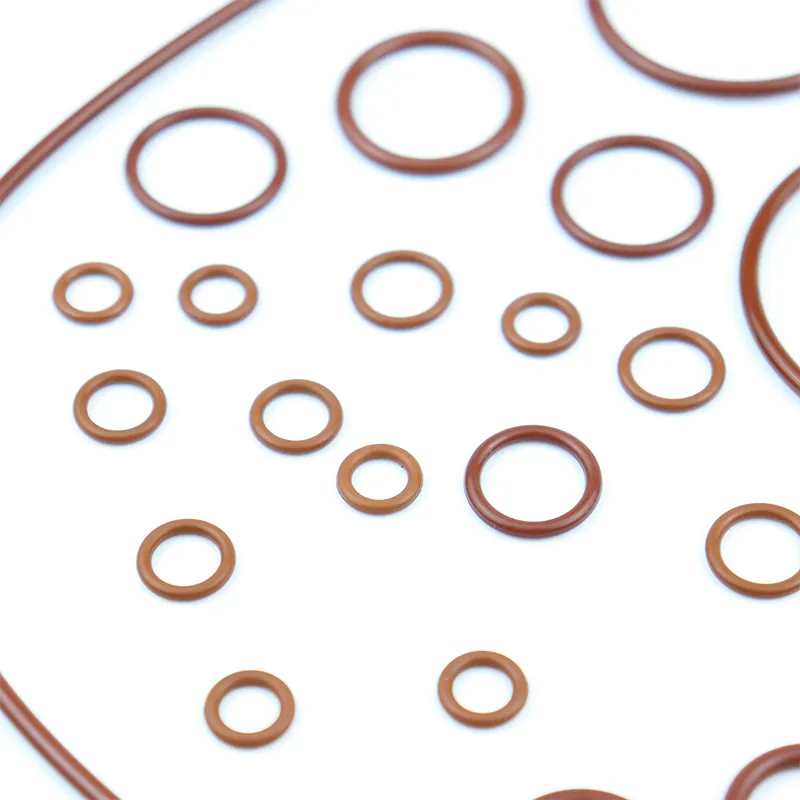

lip seal suppliers

2. Material Options Lip seals can be manufactured from various materials, including nitrile rubber, fluorocarbon, silicone, and polyurethane. Each material has distinct properties that make it suitable for specific applications. A good supplier should offer a range of material options and consult with customers to identify the best choice based on their operational requirements.

3. Customization and Flexibility Different applications may require unique dimensions and design specifications. A flexible supplier that provides customization options can cater to diverse customer needs, which is particularly beneficial for specialized machinery or applications.

4. Technical Expertise A knowledgeable supplier can provide valuable insights into sealing solutions. Technical support that assists with installation, troubleshooting, and maintenance can enhance performance and extend the lifespan of lip seals.

5. Lead Time and Availability In manufacturing, time is critical. Suppliers should be able to provide accurate lead times and maintain adequate inventory levels to meet demand. Suppliers that can deliver products promptly can help ensure that production timelines are met and minimize downtime.

6. Cost Competitiveness While quality should always be the priority, cost-effectiveness is also an important factor. Suppliers should offer competitive pricing without compromising on the quality of their seals.

Conclusion

Lip seals are indispensable components in many mechanical systems, and the choice of supplier can significantly impact the performance and reliability of these seals. By considering factors such as quality, material options, customization, technical support, lead times, and cost, businesses can make informed decisions that enhance their operations. As industries continue to evolve, the partnership with a reliable lip seal supplier becomes a vital element in maintaining efficiency and safeguarding machinery against potential failures. Ultimately, choosing the right supplier is not just about procurement; it’s about ensuring the longevity and success of a business's operations within the competitive landscape of modern engineering.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories