снеж . 11, 2024 08:15 Back to list

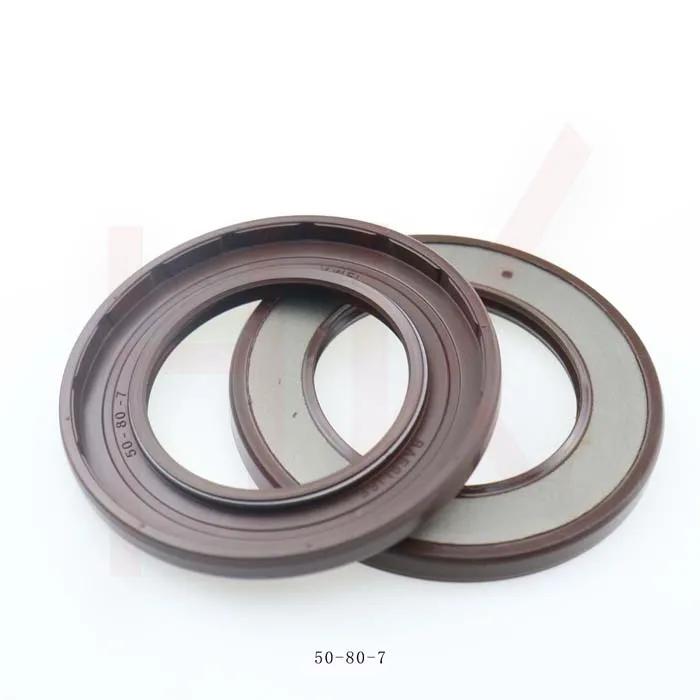

high speed rotary shaft seals

High-Speed Rotary Shaft Seals An Overview

High-speed rotary shaft seals are critical components used in various machinery and equipment to prevent the leakage of lubricants and contaminants. These seals play a vital role in ensuring the efficiency and longevity of rotating machinery, which is commonly found in industrial applications, automotive systems, and aerospace technology. As the demand for high-performance machinery grows, understanding the functionality and importance of high-speed rotary shaft seals becomes increasingly significant.

Functionality of Rotary Shaft Seals

At their core, rotary shaft seals are designed to create a barrier between the rotating shaft and the stationary housing. This barrier serves to prevent fluids, dust, dirt, and other contaminants from entering the internal components while also retaining lubricants within the system. High-speed applications present unique challenges, as the high velocities exert extreme forces on the seals, demanding materials that can withstand wear, heat, and pressure.

Typically manufactured from elastomers, PTFE (polytetrafluoroethylene), or a combination of materials, high-speed rotary seals must provide an effective sealing solution with minimal frictional resistance. This balance is crucial; excessive friction can lead to overheating and premature failure of not only the seal but the entire machine.

Importance of Material Selection

The performance of high-speed rotary shaft seals hinges greatly on the choice of materials. Different applications require various properties, such as chemical resistance, temperature tolerance, and mechanical strength. For instance, in hydraulic systems, seals might be exposed to aggressive fluids that necessitate chemical resistance, while high-temperature applications in automotive engines require seals that can withstand extreme heat without degrading.

Elastomers like nitrile rubber (NBR) and fluorocarbon rubber (FKM) are commonly used due to their excellent elasticity and resistance to wear. On the other hand, PTFE offers superior chemical resistance and can perform at high speeds without significant degradation. The selection of the seal material should also consider the operating temperature range and the presence of any abrasive particles, as these factors influence seal life and performance.

high speed rotary shaft seals

Challenges in High-Speed Applications

One of the primary challenges faced by high-speed rotary shaft seals is the balance between sealing performance and energy efficiency. As the speed increases, so does the heat generated by friction. If a seal generates too much heat, it can fail rapidly, leading to system malfunctions or costly downtime. Therefore, manufacturers strive to develop seals that not only provide excellent sealing characteristics but also minimize friction.

Another significant concern in high-speed operations is the phenomenon of 'spin-out,' where the centrifugal forces at high speeds tend to push the seal away from the shaft, compromising its ability to function effectively. Engineers design seals with specific lip configurations and materials that can counteract these forces, maintaining an effective seal even under extreme rotational speeds.

Innovations and Future Trends

Innovation in sealing technology continues as manufacturers seek to adapt to the demands of modern machinery. The development of hybrid seals, which combine the best features of elastomers and PTFE, is one area seeing considerable investment. These hybrid designs promise enhanced performance across a range of conditions, contributing to longer service life and reduced maintenance needs.

Moreover, advances in manufacturing techniques, such as 3D printing and precision engineering, are enabling the production of seals with tailored geometries that improve their fit and sealing capabilities. As industries push toward automation and smart technology, the integration of sensors in seals to monitor wear and performance is also becoming a reality, allowing for predictive maintenance and enhanced reliability.

Conclusion

In summary, high-speed rotary shaft seals are indispensable in numerous applications, playing a crucial role in maintaining system integrity and performance. The proper selection of materials, innovative designs, and continuous advancements in sealing technology will dictate the future of these components. As industries continue to evolve towards higher speeds and more stringent performance requirements, the importance of high-quality rotary shaft seals will remain a key focus for engineers and manufacturers alike, ensuring the reliability and efficiency of modern machinery.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories