Верас . 25, 2024 15:12 Back to list

Understanding Gearbox Seals and Their Importance in Machinery Performance and Longevity

Understanding Gearbox Seals Essential Components for Machinery Efficiency

Gearboxes play a pivotal role in the machinery sector, serving as the heartbeat that regulates torque and speed in various applications. However, the efficiency and longevity of gearboxes are significantly influenced by one crucial component seals. Gearbox seals ensure that lubricants remain contained within the gearbox while preventing contaminants from entering. This article delves into the importance of gearbox seals, their types, and maintenance practices.

The Importance of Gearbox Seals

Gearbox seals are designed to maintain a seal around the gearbox components, ensuring optimal performance. They prevent the leakage of lubricants, which are vital for minimizing friction and enhancing the gearbox's operational efficiency. Without effective sealing, the lubricant can escape, resulting in increased wear and tear on the gears, overheating, and potentially catastrophic failures. Additionally, contaminants such as dust, dirt, and moisture can enter the gearbox if seals fail, leading to corrosion and further degradation of the internal parts.

Types of Gearbox Seals

There are several types of seals used in gearboxes, each designed to meet specific performance requirements and environmental conditions. Here are some of the most common types

1. Rotary Seals Often used in applications with rotating shafts, rotary seals prevent the leakage of lubricants around moving parts. Their design facilitates the smooth rotation of the shaft while ensuring a tight seal.

2. O-Rings These circular seals are made from elastomers and are commonly used in static and dynamic applications. They create a seal by being compressed between two surfaces, providing excellent resistance to various fluids.

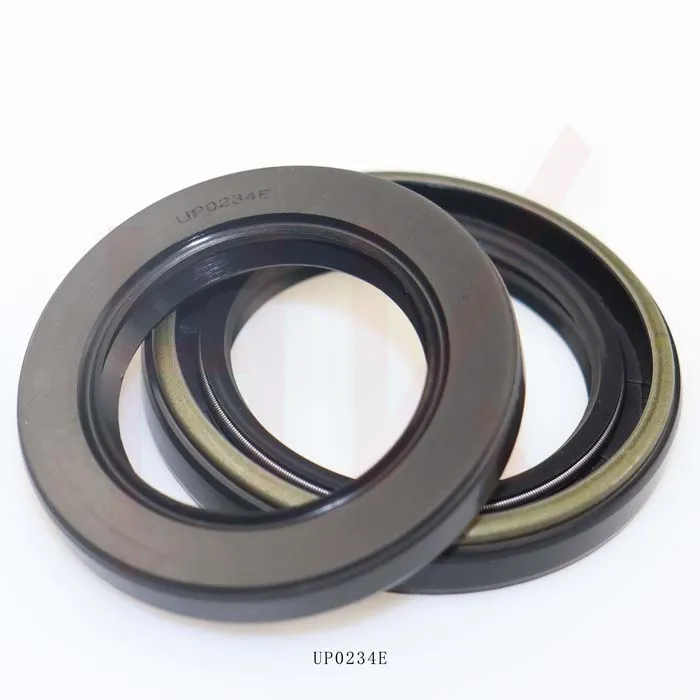

3. Lip Seals Lip seals have a flexible lip that maintains a contact seal with the rotating shaft. They are particularly effective in preventing the ingress of dirt and moisture while retaining lubricant.

gearbox seals

4. Gaskets Although not always classified as a seal per se, gaskets are vital in sealing flanged connections. They provide a barrier between two stationary surfaces, ensuring that leakage does not occur at the joint.

Maintenance Practices for Gearbox Seals

To ensure the longevity of gearbox seals and, consequently, the entire gearbox assembly, regular maintenance is essential. Here are some best practices

- Regular Inspections Schedule periodic inspections to check for signs of wear, such as cracks or deformations in seals. Early detection can prevent significant issues down the line.

- Lubricant Quality Use high-quality lubricants compatible with the seals. Poor-quality lubricants can degrade seals over time, leading to leaks.

- Environmental Considerations Protect gearboxes from harsh environmental conditions. Implementing dust covers and ensuring that the working environment is clean can prolong the life of seals.

- Proper Installation Ensure seals are installed correctly, following manufacturer guidelines. Improper installation can lead to seal failure, resulting in costly repairs.

Conclusion

Gearbox seals are indispensable for the reliable operation of machinery. With their ability to contain lubricants and exclude contaminants, they play a critical role in safeguarding the health of gearbox systems. By understanding their importance, types, and maintenance practices, operators can ensure optimal performance and longevity of their equipment. Investing time and resources in maintaining gearbox seals ultimately leads to reduced downtime, lower repair costs, and enhanced productivity in any machinery operation.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories