Ліст . 21, 2024 00:19 Back to list

30x52x7 seal

The Importance of 30x52x7% Seals in Engineering Applications

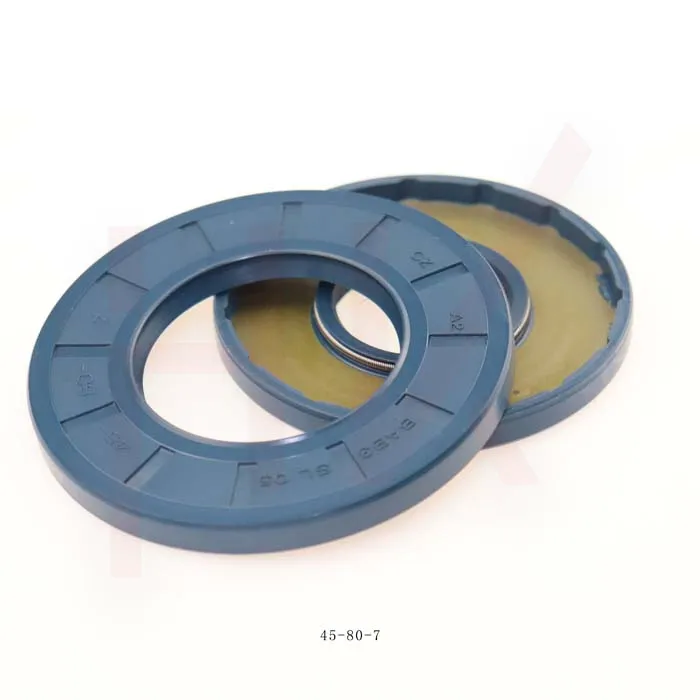

In the realm of engineering, precision and reliability are paramount. One crucial component that ensures functionality and longevity in various mechanical systems is the seal. Among the plethora of seal designs, the 30x52x7% seal stands out due to its unique specifications and versatile applications.

The Importance of 30x52x7% Seals in Engineering Applications

Seals play an essential role in preventing the leakage of fluids and contaminants between rotating and stationary components. The 30x52x7% seal is often employed in applications found in automotive, aerospace, and industrial machinery. In automotive applications, for instance, these seals help maintain lubrication within engines, preventing oil leaks and safeguarding against dirt ingress, thereby extending the lifespan of the vehicle’s components.

30x52x7 seal

The design of the 30x52x7% seal often features advanced materials that enhance its durability and resistance to wear. Such materials can withstand high pressures and temperatures, ensuring stability even in demanding environments. This is particularly important in applications where friction and heat generation are prevalent, as the integrity of the seal directly affects operational efficiency.

Additionally, the easy installation and maintenance of seals like the 30x52x7% contribute to their popularity. Engineers appreciate components that minimize downtime and simplify repair processes. When a seal does wear out, replacements can be swiftly executed, allowing machinery to resume operation with minimal delay.

Furthermore, the flexibility of these seals extends to various industries. From hydraulic systems to manufacturing equipment, the 30x52x7% seals are integral in preserving operational efficacy and reliability. As technology evolves, innovations in seal design are expected, further enhancing performance and applicability.

In conclusion, the 30x52x7% seal is more than just a component; it is a vital element in ensuring the functionality and longevity of mechanical systems. With its specific dimensions, robust materials, and versatile applications, it exemplifies the significance of quality seals in modern engineering practices.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories