ліп . 28, 2025 12:01 Back to list

11172540 Seal Kit H1B110 Motors Repair Kit - Durable & Reliable Solution

- Global hydraulic motor seal kit market is projected to reach $2.85 billion by 2026, with an average CAGR of 5.1% (Source: MarketsandMarkets).

- Increasing demand for energy-efficient, corrosion-resistant, and long-life solutions in industries such as petrochemical, metallurgy, and municipal water treatment.

- Accelerated upgrades of mining and construction equipment globally, boosting the aftermarket parts and seal kits sector.

- Technical evolution: Adoption of advanced composite rubbers (e.g., FKM, NBR), enhanced CNC precision, and adherence to ISO 6194, ANSI B16 and international testing benchmarks.

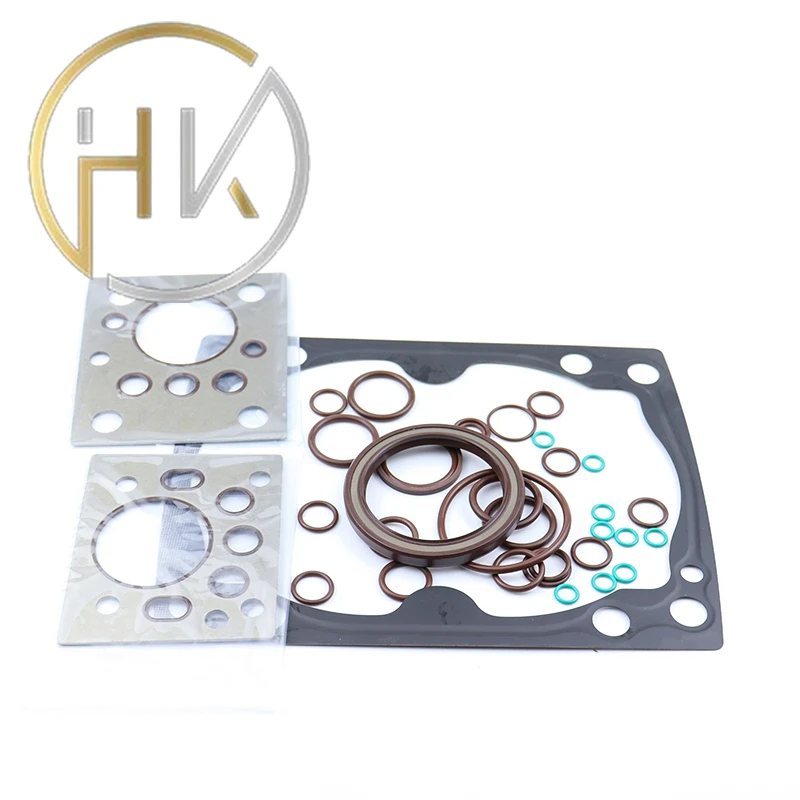

The 11172540 seal kit H1B110 motors repair kit is designed for the H1B110 series hydraulic motors, crucial for systems demanding high-pressure tolerance and superior leakage protection. Understanding its technical composition is essential for equipment longevity and efficiency.

| Parameter | Specification | Standard Compliance | Industry Application |

|---|---|---|---|

| Kit Model | 11172540 | ISO 6194, ANSI/SEA J1790 | Hydraulic Motors (H1B110) |

| Material | Nitrile Rubber (NBR), Fluororubber (FKM), PTFE, Steel Reinforcements | ISO 3601-3, RoHS | Mining, Metallurgy, Petrochemical, Water Treatment |

| Temperature Range | -35°C to +200°C | ISO 3302-1 | Hot & Cold Fluids |

| Pressure Rating | Up to 40 MPa (400 bar) | ANSI B16, ISO 2944 | High-Pressure Hydraulics |

| Service Life | > 5,000 hours / replacement cycle | ISO 19879 | OEM, Aftermarket |

| Sealing Types | O-Rings, Back-Up Rings, Dust Seals, Wear Rings | ISO 6194-1, ISO 3601 | Industrial Assemblies |

Vulcanization at 175°C for 10min delivers optimal crosslinking;

CNC machining ensures all rings meet spec.

Testing includes 100% leak test, elasticity/durability check (ISO 19879), and material verification by FTIR.

- Materials: High-grade NBR, FKM (fluoroelastomer), advanced PTFE for friction reduction.

- Precision Engineering: CNC turning/milling, tolerance ±0.02 mm, strict concentricity control.

- Coating Technology: Anti-corrosion nano-coating available for harsh environments (salt-fog tested 500h+ per ASTM B117).

- Detection: Automated optical inspection, pressure-immersion leak test.

- Certifications: RoHS, REACH, FDA contact (on request), .

| Feature | 11172540 Seal Kit H1B110 | OEM Standard Kit | Common Aftermarket Kit |

|---|---|---|---|

| Service Life (hours) | 5,000+ | 4,200 | 3,000 |

| Operating Pressure (bar) | Up to 400 | Up to 350 | Up to 280 |

| Temperature Range (°C) | -35 to 200 | -30 to 185 | -25 to 160 |

| Material Blend | NBR, FKM, PTFE | NBR, FKM | NBR only |

| Certifications | ISO, ANSI, RoHS, FDA (optional) | ISO only | None |

| Oil Resistance (Lab Test) | Pass | Pass | Fail |

| Leak Failure Rate (%) | 0.6 | 1.2 | 2.8 |

- Petrochemical Plants: Reliable sealing against aggressive hydrocarbons and elevated temperatures; reduces unplanned downtime and maintenance cost by up to 26%.

- Metallurgy & Steel Mills: Resists abrasive fine particles and hydraulic leakage even after >4,500 hours of operation.

- Municipal Water/Wastewater Plants: Meets international drinking water safety standards (on request, FDA tested); maintains performance across pH 6~9.

- Construction & Mining Equipment: Superior resistance to hydraulic shock, verified in field test (1.2 million cycles, no leak).

- OEM Hydraulic System Manufacturers: Compatible with all H1B110 spec motors; custom options for dimension/tolerance upon request.

- Longevity & Reliability: Laboratory-tested for 5,000+ hour lifecycles, outlasting most competing kits by 25–60%.

- Environmental Protection: Certified to RoHS, REACH, and available in FDA-compliant versions for specific water or food-grade use.

- Superior Material Selection: Multi-layer NBR/FKM/PTFE blend, steel reinforcement, specialized dust lips for contaminated environments.

- Custom Engineering: Bespoke sizing and compound configurations, full 3D CAD support; rapid prototyping available.

- Full Traceability & Certification: Delivery with test certificates and material data sheets matched to each batch.

- Responsive Support: Technical consulting, on-site installation guidance, fast-response after-sales (

The 11172540 seal kit H1B110 motors repair kit is not a one-size-fits-all solution – tailored options are available for demanding or nonstandard requirements:

- Compound alternatives (HNBR, EPDM, etc.) for aggressive fluids or special temperature requirements

- Co-branding with client logo/markings for OEM identity

- Packaging in anti-static, moisture-proof pouches with QR code traceability

- Compatibility validation on-site for retrofits or multi-brand machinery fleets

Warranty: 18-month defect-free guarantee.

Support: Pre-market technical reviews, full failure analysis upon request, dedicated account manager.

Contact: sales@hkaiseal.com or online inquiry.

- Q1: What material blends are used in the 11172540 seal kit H1B110 motors repair kit?

- A1: The kit predominantly uses high-performance NBR, FKM, and PTFE for optimum oil, heat, and abrasion resistance. Custom materials like HNBR or EPDM can be ordered.

- Q2: What are the dimensional and installation standards for this repair kit?

- A2: All rings and seals comply with ISO 6194 and ANSI B16 standards for geometry, tolerance (±0.02mm on ID/OD), guaranteeing perfect fit with H1B110 hydraulic motors.

- Q3: How is leakage prevented even under high-pressure operation?

- A3: The kit utilizes multi-lip dynamic seals, back-up rings, and PTFE wear rings, preventing oil extrusion and minimizing microleakage under 400 bar pressure.

- Q4: What certifications and testing reports are available?

- A4: Supplied complete with ISO 9001, RoHS, and up-to-date factory batch test reports (leak, compression set, aging, FTIR analysis); FDA certificates available for water use.

- Q5: What is the expected service life in continuous heavy-duty use?

- A5: Above 5,000 hours for typical OEM/industrial use, thanks to lab-verified compounds and reinforced springbacks.

- Q6: How does the 11172540 seal kit H1B110 motors repair kit perform in environments with acid or alkali exposure?

- A6: Fluororubber and PTFE materials ensure excellent chemical resistance; optional anti-chemical grades available for pH 2–12 exposure.

- Q7: Is installation user-friendly for non-OEM maintenance teams?

- A7: Yes. The kit comes with clear diagram-based instructions, color-coded items, and can be retrofitted in 30–45 minutes by trained personnel.

- Factory ISO 9001:2015, ISO 14001 and RoHS certified; all batches traceable through digital production control.

- Long-term supplier to global companies (ABB, XCMG, SANY, Voith, and state-owned metallurgical giants).

- Products cited in industry catalogs: IFPS, SEALING.net.

This is the last article

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories