Noy . 19, 2024 18:57 Back to list

hydraulic cylinder seal kits

Understanding Hydraulic Cylinder Seal Kits

Hydraulic cylinders are essential components in various machinery and equipment used across multiple industries, including construction, manufacturing, and automotive. These cylinders rely on seal kits to maintain their functionality and efficiency. In this article, we will explore the significance of hydraulic cylinder seal kits, their components, and their importance in hydraulic systems.

What are Hydraulic Cylinder Seal Kits?

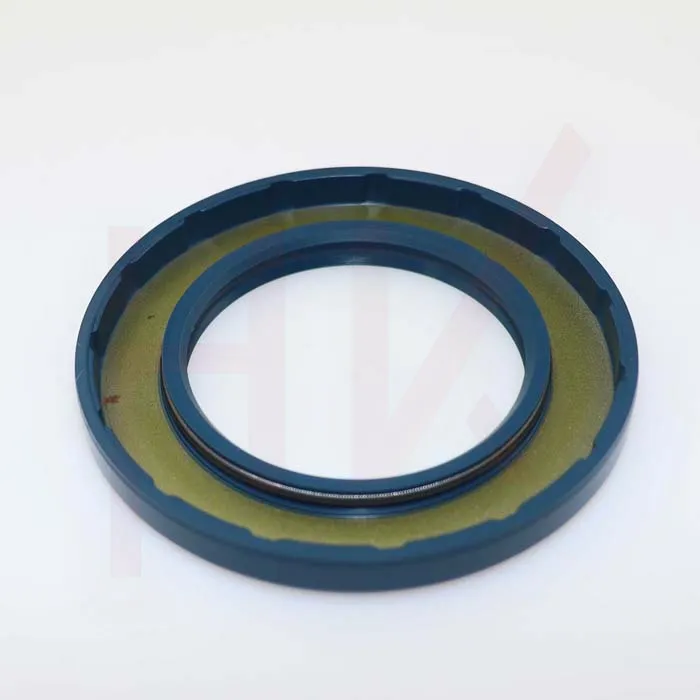

Hydraulic cylinder seal kits are collections of various sealing elements designed to prevent fluid leakage while allowing the cylinder to operate smoothly. These kits typically contain seals, O-rings, backup rings, and dust wipers, each playing a crucial role in the hydraulic system's operation. The integrity of these seals is vital, as even the slightest degradation can lead to performance issues, increased wear and tear, and, in some cases, catastrophic failure.

Components of a Seal Kit

1. Seals These are the primary components that provide a tight barrier to contain hydraulic fluid within the cylinder. Common types include rod seals, piston seals, and end-cap seals. Each type is designed to withstand specific pressures and conditions.

2. O-rings Versatile and widely used, O-rings provide additional sealing capabilities in various parts of the hydraulic system. They can be found in both static and dynamic applications, ensuring a secure fit.

4. Dust Wipers Positioned at the outer end of the cylinder, dust wipers prevent dirt and debris from entering the hydraulic system, which can cause damage and lead to seal failure.

hydraulic cylinder seal kits

Importance of Seal Kits

The proper functioning of hydraulic systems hinges on the effectiveness of seal kits. Here are some reasons why they are critical

1. Leak Prevention One of the most significant benefits of hydraulic seal kits is their ability to prevent fluid leaks. Fluid loss not only reduces system efficiency but can also pose safety hazards and environmental concerns.

2. System Longevity High-quality seal kits contribute to the overall longevity of hydraulic cylinders. By maintaining the integrity of the fluid chamber, they reduce wear on components, thereby extending the life of both the cylinder and the equipment it powers.

3. Operational Efficiency Well-maintained seals ensure that hydraulic cylinders operate at optimal performance. This reliability translates to smoother operations, reduced downtime, and lower maintenance costs.

4. Cost-Effectiveness Investing in durable hydraulic cylinder seal kits can lead to significant cost savings over time. By preventing leaks and equipment failures, businesses can avoid costly repairs and production delays.

Conclusion

In summary, hydraulic cylinder seal kits are vital components of hydraulic systems, playing a crucial role in maintaining efficiency and preventing leaks. Understanding the components and importance of these seal kits can help operators and engineers make informed decisions regarding maintenance and replacements, ultimately ensuring the smooth operation of hydraulic machinery. Investing in high-quality seal kits is not just about immediate performance; it’s about ensuring the long-term efficiency and reliability of your hydraulic systems.

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

-

Unleash the Power of Your Hydraulic Systems with Our Premium Seal Kits

NewsAug.06,2025

-

Specialized Hydraulic Seal Kits for Breakers, Pistons, and Presses

NewsAug.06,2025

-

Revitalize Hydraulic Systems with Premium Repair and Seal Kits

NewsAug.06,2025

-

Fortify Your Cylinders with Premium Sealing Solutions

NewsAug.06,2025

-

Elevate Hydraulic System Reliability with Specialized Seal Kits

NewsAug.06,2025

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

Products categories