Dek . 11, 2024 09:51 Back to list

25x47x7 Oil Seal Specifications and Applications for Machinery Maintenance

Understanding the Importance of 25x47x7 Oil Seals in Mechanical Systems

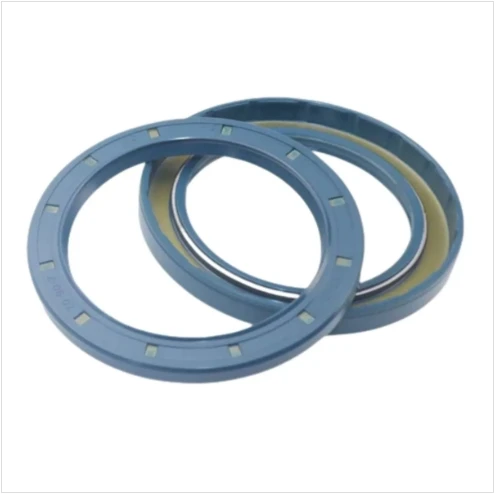

Oil seals, also known as grease seals, play a crucial role in various mechanical systems. The dimensions 25x47x7 refer to a specific oil seal size, where the first number represents the inner diameter (25 mm), the second number denotes the outer diameter (47 mm), and the last number indicates the thickness (7 mm) of the seal. Understanding the significance of oil seals, especially the 25x47x7 variant, is essential for anyone involved in machinery maintenance or assembly.

Function of Oil Seals

Oil seals are designed to prevent the leakage of lubricants from a mechanical system while simultaneously keeping contaminants such as dirt and dust from entering. This function is vital for the longevity and reliability of machinery. When lubricants leak out, it can result in insufficient lubrication, leading to increased wear and tear on components, potential overheating, and ultimately, mechanical failure. Conversely, if contaminants enter, they can cause abrasive wear, resulting in further operational issues.

The 25x47x7 oil seal is commonly used in various applications, including automotive, industrial machinery, and agricultural equipment. In vehicles, for instance, this size of oil seal is often found in differentials, gearboxes, and wheel hubs, where it helps maintain a proper lubricating environment and enhances the overall efficiency of the system.

Composition and Design

Most oil seals are made from synthetic rubber compounds such as nitrile, fluorocarbon, or silicone, which provide excellent resistance to oil, heat, and aging. The choice of material often depends on the specific operational conditions it will face. For example, nitrile rubber is commonly used in environments where petroleum-based oils are present, while fluorocarbon seals are preferred for high-temperature or chemically aggressive applications.

25x47x7 oil seal

The design of the oil seal is also critical. It typically includes a lip that makes contact with the rotating shaft. This lip creates a barrier that effectively contains the lubricant while preventing external contaminants from penetrating the system. The design may also incorporate features like spring-loaded lips to enhance sealing performance under varying operating conditions.

Installation and Maintenance

Proper installation of an oil seal is crucial to ensure its effectiveness. The surface onto which the oil seal is installed must be clean and free of damage to avoid compromising the seal’s function. If there are any nicks or debris on the shaft or seal seat, it can lead to premature failure. It is also important to ensure that the seal is not pressed too far into its housing, as this can lead to distortion and improper sealing.

Maintenance involves periodic inspections to detect signs of wear or leakage. If an oil seal begins to leak, it is essential to replace it promptly to avoid more significant problems. Regular checks on the surrounding components, as well as the lubricant condition, can extend the oil seal's lifespan and overall system performance.

Conclusion

The 25x47x7 oil seal is a vital component in various machines, safeguarding against oil leakage and contamination ingress. Understanding its importance, composition, and maintenance is crucial for ensuring the optimal functioning of mechanical systems. Whether in automotive or industrial applications, selecting the right oil seal and ensuring proper installation and care can prevent costly downtimes and repairs, making it an indispensable aspect of machinery maintenance.

In summary, oil seals may seem like small components, but their impact on machine performance is significant. The 25x47x7 oil seal exemplifies the essential role of sealing solutions in maintaining the integrity and longevity of mechanical systems. By investing in quality oil seals and adhering to best practices for installation and maintenance, operators can ensure consistent and reliable operation in various applications.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories