ታኅሣ . 05, 2024 21:51 Back to list

Understanding Wiper Seals for Enhanced Hydraulic Cylinder Performance and Reliability

Understanding Wiper Seals in Hydraulic Cylinders

Hydraulic cylinders are fundamental components in various industries, providing the power needed to perform a wide range of tasks, from heavy machinery operations to precision equipment movements. One critical piece of technology within these hydraulic systems is the wiper seal. This article delves into the role of wiper seals in hydraulic cylinders, their construction, types, and importance in maintaining hydraulic systems.

What is a Wiper Seal?

A wiper seal, often referred to as a dust seal or scraper, is a type of seal installed at the outer part of a hydraulic cylinder. Its primary function is to prevent dirt, debris, water, and other contaminants from entering the hydraulic cylinder as the piston extends and retracts. This contamination can lead to severe issues, including increased wear on internal components, fluid leakage, and ultimately, system failure.

Construction of Wiper Seals

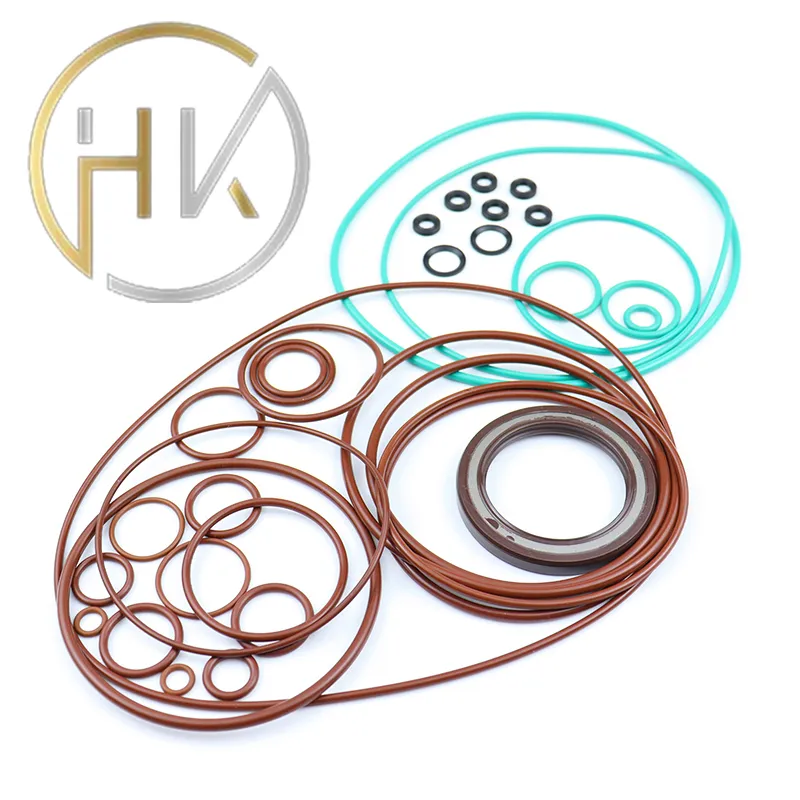

Wiper seals are typically made from elastomeric materials such as rubber or polyurethane, chosen for their flexibility, durability, and resistance to harsh environments. The design of wiper seals is crucial for their functionality. They are usually shaped like a 'wiper' to effectively clear away contaminants from the cylinder rod as it moves in and out of the cylinder body.

The design may feature a series of lips or ribs that help create a barrier against foreign particles. The specific configuration of these lips helps to manage the pressure and enables the seal to function efficiently under various working conditions, particularly in hydraulic systems that are subjected to high pressures and rapid movements.

Types of Wiper Seals

Wiper seals come in various designs and materials, each suited to specific operating conditions

. Some common types include1. U-Cup Wiper Seals These feature a U-shaped profile that can effectively scrape debris off the rod during extension and retraction. 2. T-Seals These are designed like a T and provide excellent sealing performance due to their increased surface area.

wiper seal hydraulic cylinder

3. V-Rings This type utilizes a V-shaped lip to maintain contact with the rod and is highly effective in situations where high levels of contaminants are present.

4. Custom Seals For specialized applications, custom wiper seals can be designed to fit specific machinery, taking into account the particular environmental stresses they must withstand.

Importance of Wiper Seals

The importance of wiper seals in hydraulic cylinders cannot be overstated. First and foremost, they help prolong the life of the hydraulic system. By preventing contamination, wiper seals ensure that the internal components of the cylinder, such as the piston and other seals, are not damaged by debris. This reduces maintenance costs and minimizes downtime, leading to increased productivity.

Moreover, wiper seals contribute to the overall efficiency of hydraulic systems. Contaminants in hydraulic fluid can lead to improper functioning, energy loss, and inefficient operations. By ensuring a clean environment, wiper seals help maintain the system’s efficiency.

Regular Maintenance and Replacement

While wiper seals are designed to last, they cannot last indefinitely. Regular inspection is crucial. Signs of wear, such as cracks, splits, or deformities, indicate that the wiper seal may need to be replaced. It is advisable to follow manufacturer guidelines regarding maintenance schedules and to promptly address any issues to avoid more significant problems down the line.

Additionally, selecting the right wiper seal for a specific application is essential. Factors such as working pressure, temperature ranges, and the type of fluid being used should influence the selection process. Consulting with manufacturers or experts in hydraulic systems can provide valuable insights into the best choices for different scenarios.

Conclusion

In conclusion, wiper seals are a vital component of hydraulic cylinders, protecting internal parts from contaminants and ensuring the longevity and efficiency of hydraulic systems. Understanding their function, types, and maintenance requirements is essential for anyone involved in machinery operation or hydraulic system design. By prioritizing the condition and quality of wiper seals, industries can enhance performance and reduce operational costs, ensuring a smoothly running hydraulic system for years to come.

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

-

Unleash the Power of Your Hydraulic Systems with Our Premium Seal Kits

NewsAug.06,2025

-

Specialized Hydraulic Seal Kits for Breakers, Pistons, and Presses

NewsAug.06,2025

-

Revitalize Hydraulic Systems with Premium Repair and Seal Kits

NewsAug.06,2025

-

Fortify Your Cylinders with Premium Sealing Solutions

NewsAug.06,2025

-

Elevate Hydraulic System Reliability with Specialized Seal Kits

NewsAug.06,2025

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

Products categories