ጥቅም . 16, 2024 21:51 Back to list

Shaft Seals and Wipers for Enhanced Performance and Durability in Machinery

Understanding Shaft Wipers Essential Components in Mechanical Systems

Shaft wipers play a critical role in various mechanical systems by preventing contaminants from entering sensitive areas, particularly around rotating shafts. These components are often overlooked but are essential for maintaining the integrity and longevity of machinery. In this article, we’ll delve into what shaft wipers are, their functions, types, materials, and the advantages they offer to different industries.

What Are Shaft Wipers?

Shaft wipers, also known as shaft seals or dust wipers, are devices designed to clean the surfaces of rotating shafts and prevent dirt, dust, and other contaminants from entering the machinery. They typically consist of a flexible lip that contacts the shaft, creating a seal that helps to keep the shaft clean. This sealing action is crucial, especially in equipment that operates in harsh environments.

Functions of Shaft Wipers

1. Contaminant Exclusion The primary function of shaft wipers is to prevent dust, dirt, and other foreign materials from entering the shaft assembly, which could lead to premature wear and failure of the components inside machinery.

2. Maintenance of Lubrication By keeping contaminants at bay, shaft wipers help maintain the necessary lubrication levels within the machine. This lubrication is crucial for smooth operation and reduced friction between moving parts.

3. Reduction of Wear and Tear By blocking out harmful particles, shaft wipers help to significantly reduce the wear and tear on the shaft and associated components. This leads to improved reliability and a longer lifespan for the machinery.

4. Minimization of Downtime With proper sealing and cleaning functions, the need for maintenance is reduced, leading to minimized downtime and operational costs for businesses.

Types of Shaft Wipers

Shaft wipers come in various types, each designed for different applications

1. Standard Wipers These are simple designs that typically feature a single wiping lip. They are used in general applications where the operating conditions are not extremely harsh.

2. Heavy-Duty Wipers Designed for more challenging environments, these wipers often incorporate additional features such as dual lips or reinforced frames to withstand high pressures and temperatures.

3. Custom Wipers For specific applications, manufacturers often provide customized wiper solutions tailored to the unique requirements of particular equipment or environments.

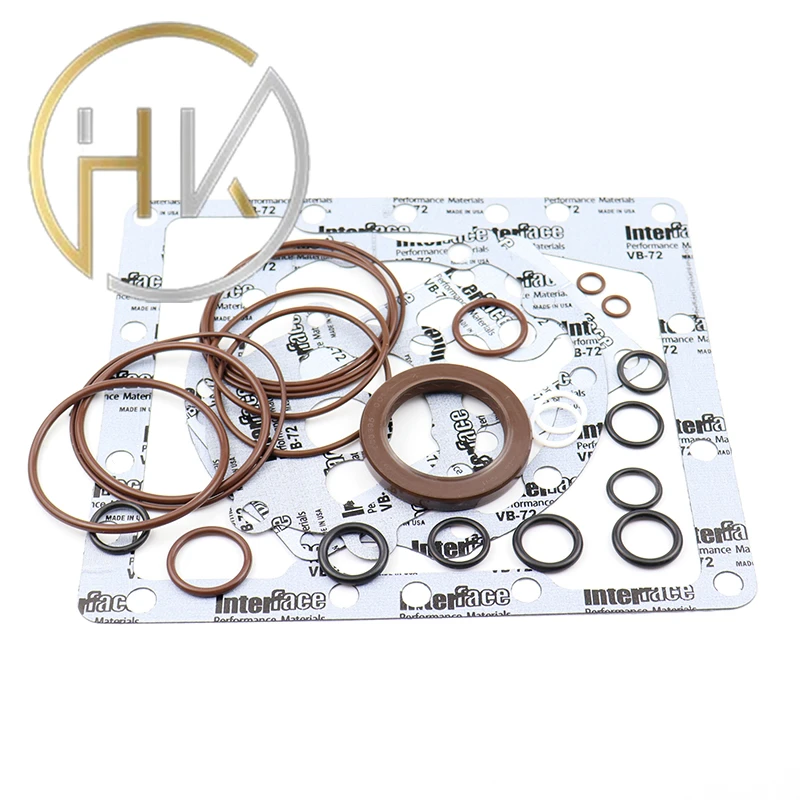

shaft wipers

Materials Used in Shaft Wipers

The material used for shaft wipers significantly impacts their performance and durability. Common materials include

1. Rubber Often used for its elasticity and ability to conform to the shaft surface, rubber is a popular choice for standard shaft wipers. However, its performance can degrade in extreme temperatures.

2. Polyurethane Offering greater resistance to wear and tear compared to rubber, polyurethane wipers are ideal for applications involving abrasive particles.

3. Metal Reinforced Materials In heavy-duty applications, metals may be integrated into the wiper design to enhance strength and durability.

Advantages of Using Shaft Wipers

The use of shaft wipers in machinery offers several key benefits

1. Enhanced Equipment Performance By preventing contaminants from reaching critical components, shaft wipers help maintain the overall performance of the machine.

2. Cost-Effectiveness Reducing the frequency of maintenance and downtime translates to lower operational costs, making shaft wipers a worthwhile investment.

3. Improved Safety Maintaining clean shafts reduces the risk of catastrophic failures, thereby improving the safety of the overall operation.

4. Versatility Shaft wipers are used in various industries, including automotive, industrial machinery, aerospace, and agriculture, showcasing their versatility.

Conclusion

In conclusion, while they may often be underestimated, shaft wipers are fundamental components that contribute to the reliability and efficiency of mechanical systems. Understanding their function, types, materials, and advantages can help businesses make informed decisions regarding maintenance practices and equipment choices. By investing in quality shaft wipers, companies can ensure their machinery operates smoothly and efficiently for years to come.

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

-

Unleash the Power of Your Hydraulic Systems with Our Premium Seal Kits

NewsAug.06,2025

-

Specialized Hydraulic Seal Kits for Breakers, Pistons, and Presses

NewsAug.06,2025

-

Revitalize Hydraulic Systems with Premium Repair and Seal Kits

NewsAug.06,2025

-

Fortify Your Cylinders with Premium Sealing Solutions

NewsAug.06,2025

-

Elevate Hydraulic System Reliability with Specialized Seal Kits

NewsAug.06,2025

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

Products categories