ኅዳር . 07, 2024 09:24 Back to list

mechanical seal kit

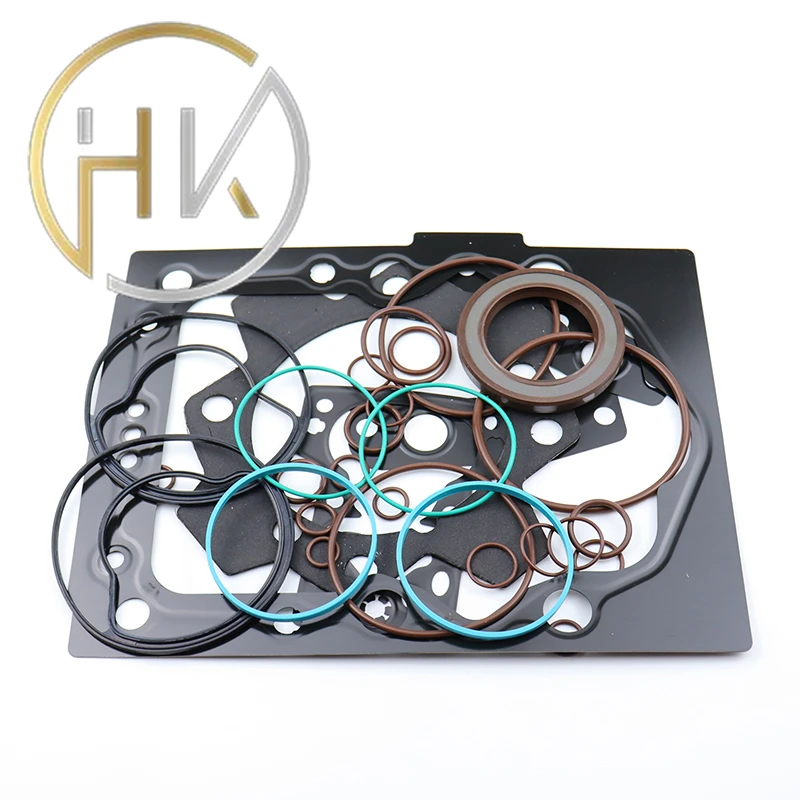

Understanding Mechanical Seal Kits Key Components and Applications

Mechanical seals play a vital role in various industries, providing a reliable solution for preventing fluid leakage in rotating equipment. A mechanical seal kit is an essential component for maintaining and repairing this critical technology. These kits typically contain all the necessary parts to replace or upgrade a mechanical seal, ensuring that equipment operates efficiently and safely.

What is a Mechanical Seal?

A mechanical seal is a device used to seal the interface between stationary and rotating components, such as pump shafts and compressors. Its primary purpose is to prevent the leakage of fluids, gases, or even powder-like substances during operation. By maintaining a leak-proof environment, mechanical seals help minimize product loss, reduce environmental contamination, and enhance the overall safety of the system.

Components of a Mechanical Seal Kit

A standard mechanical seal kit generally contains several key components, including

1. Seal Faces These are the primary elements that provide sealing. Typically made of high-quality materials like ceramic, carbon, or tungsten carbide, they create a barrier to prevent leakage.

2. Spring Mechanism The seals often come with a spring mechanism that helps maintain the contact pressure between the seal faces. Springs can be helical or wave-type, depending on the design and application requirements.

3. O-Rings and Gaskets These elastomeric components aid in sealing the interface and often play a crucial role in ensuring tightness. They are available in various materials, including nitrile, Viton, and EPDM, to accommodate different fluid characteristics.

4. Sleeve or Adapter In some applications, a sleeve or an adapter might be included in the kit to facilitate installation on the pump shaft.

mechanical seal kit

Applications of Mechanical Seal Kits

Mechanical seal kits are used in a wide range of applications across multiple industries, including

- Chemical Processing To handle aggressive chemical fluids, mechanical seals provide safe transportation with minimal leakage.

- Water and Wastewater Treatment They are crucial for pumps used in water supply and sewage systems to prevent ground and surface water contamination.

- Oil and Gas Mechanical seals are utilized in various applications, from extraction to refining, ensuring operational safety and efficiency.

- Food and Beverage In this industry, maintaining hygiene is paramount. Mechanical seals help in preventing contamination while complying with regulatory standards.

- Pharmaceuticals Similar to the food and beverage sector, they ensure the integrity of products by preventing contamination and ensuring adherence to safety standards.

Conclusion

Investing in a mechanical seal kit is essential for businesses that rely on equipment capable of managing fluid dynamics. Proper selection and maintenance of mechanical seals not only enhance efficiency but also safeguard the operational integrity of machinery. Regular inspection and timely replacement of seals can save companies from costly downtimes and environmental risks. As industries continue to evolve, the demand for reliable sealing solutions will only increase, making mechanical seal kits a critical component of modern engineering and maintenance practices.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories