ኅዳር . 15, 2024 17:05 Back to list

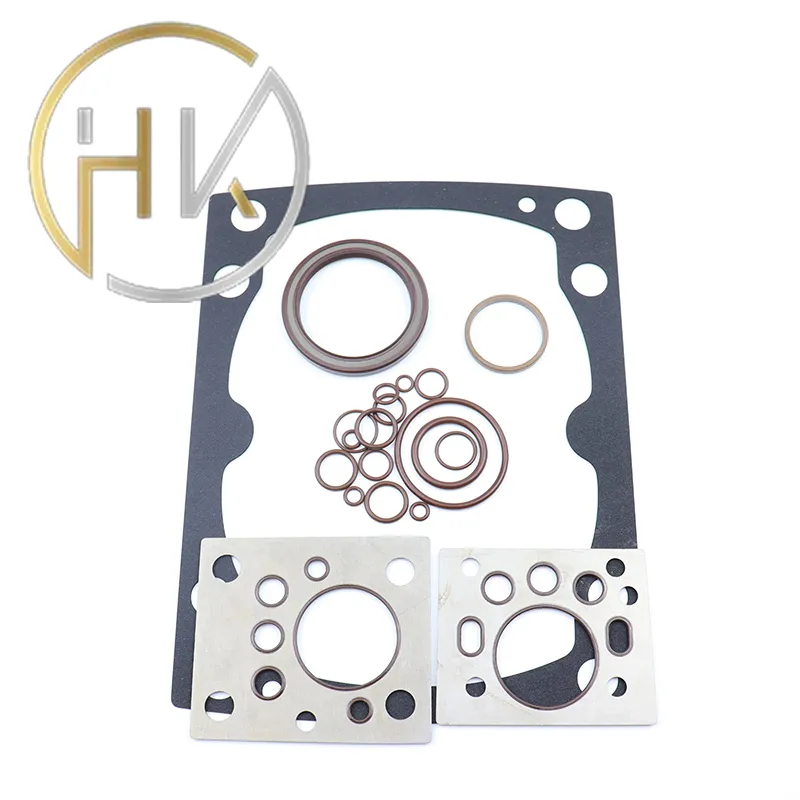

gear pump seal kit

Understanding Gear Pump Seal Kits Importance and Functionality

Gear pumps are widely utilized in various industrial applications due to their efficient fluid transfer capabilities. These pumps operate by using gears to move fluids, making them suitable for handling viscous materials. One crucial component that ensures the reliability and efficiency of gear pumps is the seal kit. In this article, we will explore the significance of gear pump seal kits, their components, maintenance needs, and their role in extending the service life of gear pumps.

What is a Gear Pump Seal Kit?

A gear pump seal kit is an assembly of seals, O-rings, gaskets, and other components designed to prevent fluid leaks from the pump housing. These kits are specifically engineered for gear pumps, taking into account the unique pressures and movements within the pump. The performance of a gear pump is heavily dependent on the integrity of its seals, as leaks can lead to inefficiencies, contamination of fluids, and ultimately, mechanical failures.

Components of a Seal Kit

1. Seals The primary function of seals is to create a barrier between moving parts and protect against fluid leaks. Common types of seals used in gear pumps include lip seals and mechanical seals. Lip seals typically consist of a flexible material that conforms to the shaft, ensuring a snug fit, while mechanical seals involve multiple components that provide greater resistance to high pressures and temperatures.

2. O-Rings These circular rings are crucial for locking in fluid and preventing leaks. They are often placed at various junctures within the gear pump assembly. O-rings can be made from different materials, such as rubber and silicone, depending on the fluid being pumped and the operating conditions.

3. Gaskets Gaskets are used to fill the spaces between two mating surfaces, preventing leaks. They are often found in pump covers and end plates. Like O-rings, gaskets need to be made from materials compatible with the fluids and environmental conditions.

4. Retaining Rings These components help to secure seals in place and ensure they remain effective throughout the pump’s operation.

Importance of Seal Kits

The role of gear pump seal kits cannot be overstated. Here are some key reasons why they are essential

1. Prevent Fluid Leaks The primary purpose of seal kits is to ensure that fluids do not leak from the pump. Even minor leaks can lead to significant fluid loss, which can affect production processes and lead to costly downtimes.

gear pump seal kit

2. Maintain Operational Efficiency By preventing leaks, seal kits help maintain the pressure within the system, thus ensuring that the pump operates efficiently. Efficient operation translates to optimal performance and reduced energy consumption.

3. Extend Pump Life Regular replacement of worn-out seals and components helps avoid catastrophic failures that could lead to costly repairs or replacements of the entire pump.

4. Prevent Contamination In many applications, especially those involving food-grade or pharmaceutical fluids, leakage can lead to contamination of the product. Seal kits help to ensure that the fluids remain pure and uncontaminated.

Maintenance of Seal Kits

To get the most out of gear pump seal kits, regular maintenance and checks are necessary. Here are some tips

- Routine Inspections Periodically inspect seal kits for wear and tear. Check for visible signs of leaks or damage to the seals and O-rings.

- Replace Worn Components If any components of the seal kit are found to be worn or damaged, they should be replaced immediately to prevent further issues.

- Proper Installation When replacing seals, ensure that they are installed correctly to avoid improper sealing, which can lead to leaks.

- Use the Correct Materials Always use seal kits designed for specific gear pumps and compatible with the fluids being handled to ensure maximum efficiency.

Conclusion

Gear pump seal kits are vital components that ensure the efficient operation of gear pumps, preventing leaks, maintaining pressure, and extending the pump's service life. By understanding the components and importance of seal kits, along with the best practices for their maintenance, industries can ensure their gear pumps operate smoothly and reliably. Regular attention to seal kits will lead to enhanced performance and reduced operational costs, making them a crucial part of any maintenance strategy for gear pumps.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories