Feb . 15, 2025 11:34 Back to list

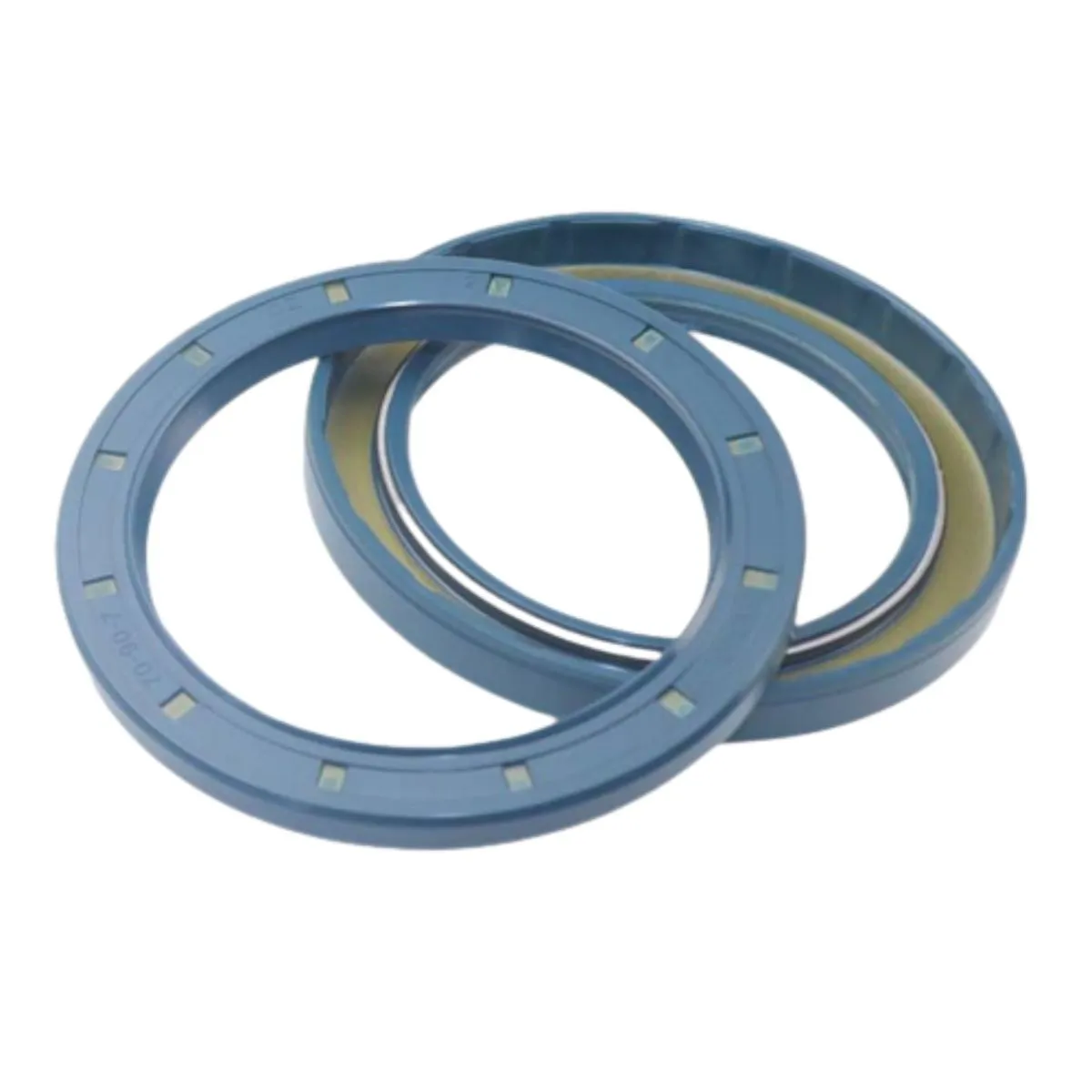

wheel hub grease seal

Trustworthiness in advising on or offering wheel hub maintenance solutions demands transparency and honesty about product efficacy. Engage with suppliers who exhibit a track record of quality assurance and offer comprehensive support, from installation guidance to after-sales service. Recommending the best seals involves not only addressing immediate requirements but also considering the long-term reliability and safety of the vehicle. To maximize the lifespan of wheel hub grease seals, maintaining optimal lubrication levels is crucial. Over-packing the bearings with grease should be avoided as it can increase friction and heat, potentially compromising the seal. Meanwhile, under-lubrication may lead to premature wear. Regular inspections help maintain equilibrium, ensuring that the seal and bearing function harmoniously. Moreover, proper installation is paramount. Mishandling during mounting can deform the seal, reducing its effectiveness. Utilise the appropriate tools and follow manufacturer guidelines to avoid inadvertently damaging the seal. Installing a seal requires precision, and any errors can lead to costly consequences down the line. In conclusion, while wheel hub grease seals may seem like a small component in the grand scheme of automotive maintenance, their role is crucial. By understanding their function, prioritizing quality in selection, and committing to proper maintenance practices, automobile professionals can ensure reliable vehicle performance and customer satisfaction. Investing time in mastering the intricacies of wheel hub components fundamentally contributes to establishing a reputation for excellence and reliability in the field of automotive repair and maintenance.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories