Feb . 18, 2025 06:40 Back to list

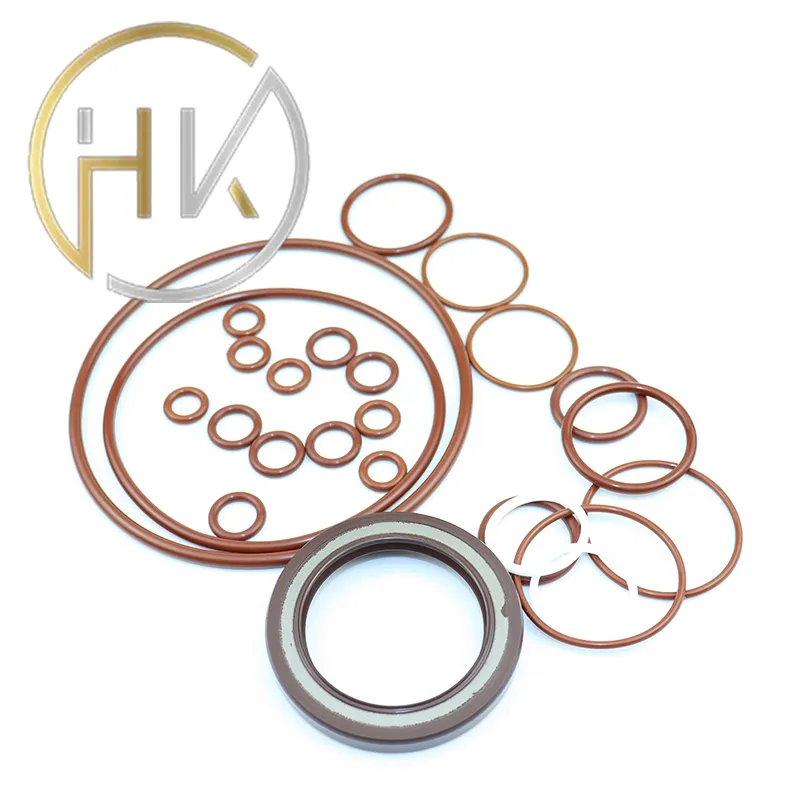

shaft oil seal

Selecting the right shaft wiper necessitates a nuanced understanding of these material properties and the specific operational conditions of the machinery. Furthermore, consulting with manufacturers or authorized distributors can provide valuable insights into customization options for specific industrial needs, ensuring optimal performance and maximum lifespan of the equipment. Establishing authoritativeness in the shaft wiper domain involves integrating technical knowledge with practical applications. Collaborating with seasoned engineers and conducting independent tests under real-world conditions enhances the authenticity of the information provided. Incorporating testimonials and reviews from notable industrial clients provides additional layers of credibility, showcasing how shaft wipers have consistently delivered on their promise of reliability and performance across various sectors. Equally important is trustworthiness, which underpins every aspect of product recommendation and integration. Transparency in communicating the limitations as well as the benefits of shaft wipers can greatly enhance the trust of potential buyers. Providing clear, concise installation guidelines and offering dedicated customer service ensure that end-users receive comprehensive support throughout the lifespan of the product. Moreover, sourcing shaft wipers from reputable manufacturers that adhere to stringent quality control and regulatory standards further reinforces trust, ensuring that the products meet consistent performance benchmarks. In sum, shaft wipers play a pivotal role in safeguarding machinery from premature wear and malfunctions. By fostering a deep understanding of their materials, applications, and benefits, businesses can optimize their machinery's performance and reliability. Through a commitment to experience, expertise, authoritativeness, and trustworthiness, we emphasize a holistic approach to selecting and utilizing shaft wipers, ensuring that industries across the board continue to operate smoothly and efficiently.

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

-

Unleash the Power of Your Hydraulic Systems with Our Premium Seal Kits

NewsAug.06,2025

-

Specialized Hydraulic Seal Kits for Breakers, Pistons, and Presses

NewsAug.06,2025

-

Revitalize Hydraulic Systems with Premium Repair and Seal Kits

NewsAug.06,2025

-

Fortify Your Cylinders with Premium Sealing Solutions

NewsAug.06,2025

-

Elevate Hydraulic System Reliability with Specialized Seal Kits

NewsAug.06,2025

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

Products categories