Des . 13, 2024 18:29 Back to list

Understanding Rotary Shaft Oil Seals for Enhanced Machinery Performance and Longevity

Understanding Rotary Shaft Oil Seals Function, Types, and Applications

Rotary shaft oil seals play a crucial role in modern machinery and automotive applications. Operating at the interface between stationary and rotating components, these seals are designed to prevent leakage of lubricants and entry of contaminants, thereby extending the lifespan of machinery and ensuring optimal performance. In this article, we will explore the function, types, and applications of rotary shaft oil seals to gain a better understanding of their significance.

Function of Rotary Shaft Oil Seals

The primary function of a rotary shaft oil seal, also known simply as an oil seal, is to retain the lubricating oil within a mechanical system while simultaneously preventing the ingress of dirt, dust, and other contaminants. These seals are critical in maintaining the pressure and functionality of the lubrication system, which is essential for reducing friction and wear between moving parts.

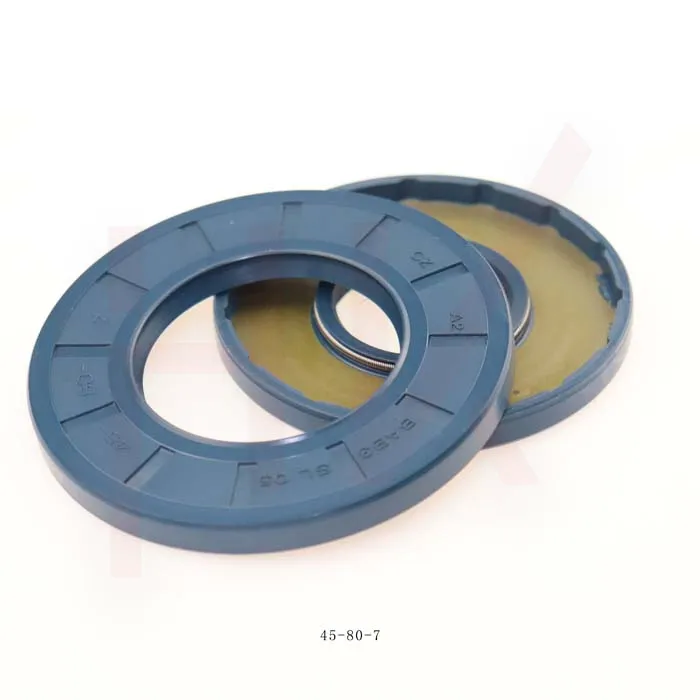

Oil seals are often made of flexible materials that can accommodate the axial movement and rotation of shafts. Typically, they consist of a rubber or elastomer sealing lip that presses against the shaft, forming a tight seal. This action minimizes the escape of oil and helps to keep harmful substances out, which can lead to premature failure of the machinery if allowed entry.

Types of Rotary Shaft Oil Seals

There are several types of rotary shaft oil seals, each designed to cater to specific applications and conditions. Here are some common types

1. Single Lip Seals These are the most basic type of oil seals, featuring a single sealing lip that presses against the shaft. They are commonly used in applications where the operating conditions are moderate, and there is no significant pressure differential.

2. Double Lip Seals These seals consist of two lips, providing an additional barrier against contamination. They are often used in more demanding applications where higher levels of dirt and water exposure are expected.

3. Spring-Loaded Seals These seals incorporate a spring that applies continuous pressure to the sealing lip, enhancing the effectiveness of the seal. They are particularly beneficial in high-speed applications, ensuring a tight fit and preventing oil leakage.

rotary shaft oil seals

4. PTFE Seals Made from polytetrafluoroethylene (PTFE), these seals are highly resistant to temperature extremes, chemical exposure, and wear. They are ideal for use in applications that require high performance under various environmental conditions.

Applications of Rotary Shaft Oil Seals

Rotary shaft oil seals find widespread use across different industries due to their vital functions. Here are some notable applications

1. Automotive In vehicles, oil seals are used in engine components, transmission systems, and differentials to prevent oil leakage and protect the internal parts from contamination. Their ability to maintain pressure in the lubrication system is essential for the smooth operation of engines.

2. Heavy Machinery Industrial equipment, such as excavators, bulldozers, and cranes, rely on oil seals to ensure that hydraulic fluids remain contained and that contaminants do not enter critical components, thereby preventing mechanical failure and extending service life.

3. Aerospace The aerospace industry demands high-performance seals that can withstand extreme pressures and temperature fluctuations. Oil seals are essential in helicopter transmissions, landing gear systems, and other critical components in aircraft.

4. Home Appliances Even everyday household appliances, such as washing machines and dishwashers, utilize rotary shaft oil seals to prevent leaks and ensure efficient operation.

Conclusion

Rotary shaft oil seals are fundamental components in a variety of mechanical systems. Their ability to effectively seal lubricants while blocking contaminants is crucial for maintaining the reliability and efficiency of equipment across numerous industries. As technology advances, the design and materials used in oil seals continue to evolve, leading to even greater performance and longevity. Understanding these seals helps engineers and technicians make informed choices in selecting the right type for their specific applications, ultimately leading to improved machinery performance and reduced maintenance costs.

-

Wiper Oil Seal: Our Commitment to Clean Hydraulics

NewsAug.13,2025

-

Hydraulic Oil Seal for Self Discharging Cars

NewsAug.13,2025

-

Hub Oil Seal for Agricultural Tractor Hubs

NewsAug.13,2025

-

Skeleton Oil Seal with NBR Material

NewsAug.13,2025

-

Rotary Lip Seal for High Pressure Applications

NewsAug.13,2025

-

Cylinder Seal Kits Our Legacy of Hydraulic Trust

NewsAug.13,2025

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

Products categories