Jan . 14, 2025 12:39 Back to list

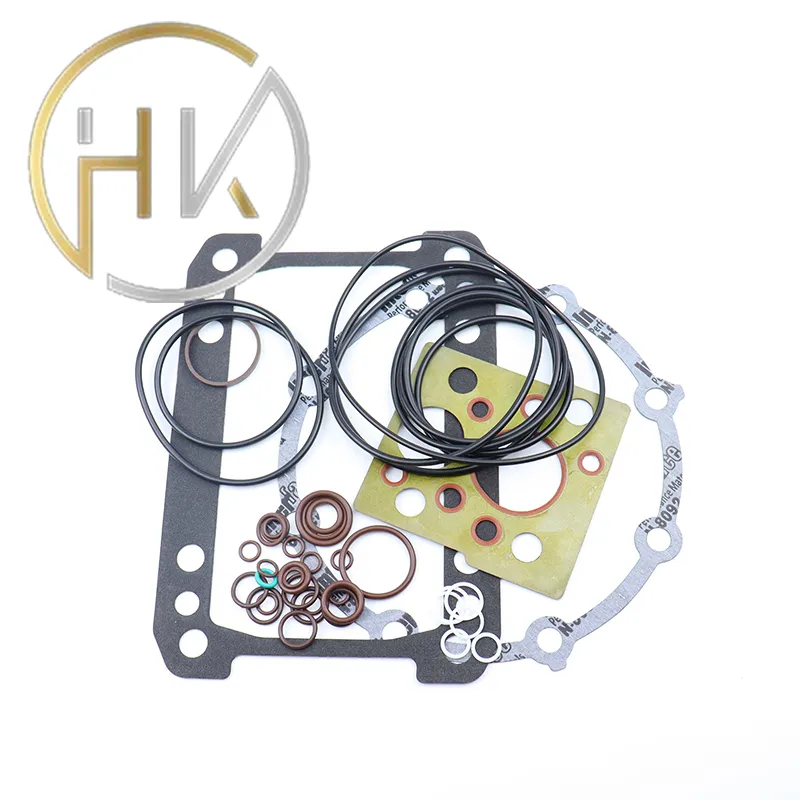

dkb seal

The voice of authority also reverberates through industry endorsements and compliance with rigorous testing standards. Reputable manufacturers subject their hub grease seals to an array of bench tests, endurance trials, and are manufactured adhering to ISO/TS standards. These seals aren't mere aftermarket components but are essential automotive parts crucial for maintaining vehicle integrity and are often crafted by companies with decades of industry trust and expertise. Building a narrative around trustworthiness also entails sharing real testimonials and grounded experiences. Vehicle owners consistently report enhanced performance and reduced maintenance woes when employing well-reviewed seal products. This anecdotal evidence, when combined with scientific validation, builds a robust case for understanding the worth of high-grade hub grease seals. In summation, the value of hub grease seals goes beyond their modest appearance. Their design reflects the pinnacle of expertise in materials science and automotive engineering, anchoring them as essential components in vehicle safety and performance. For those invested in maintaining automotive vitality, recognizing the importance of selecting superior grease seals isn't just advisable—it's imperative.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories