Des . 07, 2024 07:20 Back to list

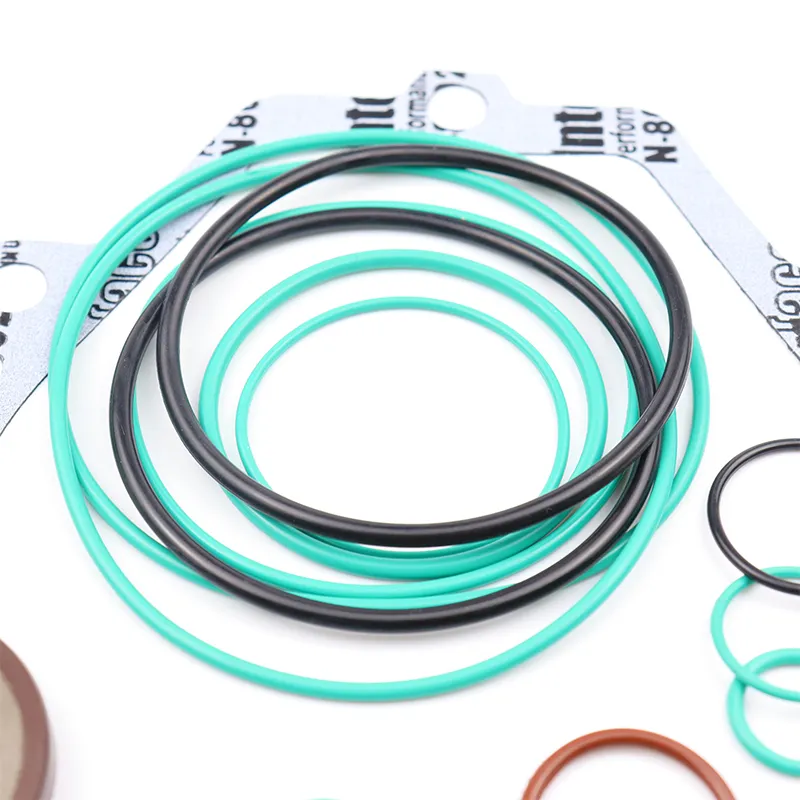

32 47 7 oil seal

Understanding the Importance of the 32% 2047% 7% Oil Seal

In the world of mechanical engineering, the importance of seals cannot be overstated. Among various types of seals used in machinery, the oil seal stands out due to its crucial role in maintaining operational efficiency and ensuring the longevity of equipment. A specific type, identified as the 32% 2047% 7% oil seal, offers unique features that make it particularly effective in various applications.

What is an Oil Seal?

An oil seal, also known as a rotary shaft seal, is a device that helps contain lubrication within machinery while preventing the ingress of contaminants such as dirt and water. Oil seals are vital in applications where rotating shafts need to maintain a lubricated environment. They are often found in engines, gearboxes, and other machinery where fluid containment is essential.

Composition and Design

The composition of an oil seal typically consists of a rubber or elastomer material that forms a flexible lip. This lip creates a tight seal against the shaft, and the design of the seal is crucial for its effectiveness. The dimensions specified as 32%, 2047%, and 7% may refer to the ratio of material to oil viscosity, design characteristics, or manufacturing tolerances which enhance the seal's performance.

1. 32% This could denote the optimal balance of polymer composition within the seal for ensuring flexibility while maintaining durability. A well-balanced material composition allows the seal to adapt to varying temperatures and pressures, which is particularly important in dynamic environments. 2. 2047% This percentage likely refers to the enhancement or capacity of the seal to withstand internal pressures and provide a robust barrier against leakage. A high-pressure rating ensures that the oil remains contained under the demands of machinery operation, driving the efficiency and reliability of the system.

3. 7% This may indicate a critical threshold for maintaining the operational efficiency of the seal, such as tolerances related to temperature variations or the ability to resist wear and tear over time.

32 47 7 oil seal

Applications

The 32% 2047% 7% oil seal is designed for a variety of applications in different industries. Here are a few critical areas where such seals prove effective

1. Automotive Applications In engines and gearboxes, oil seals help contain engine oil, preventing leakage while ensuring that the lubrication remains intact. This is essential for the optimal performance of automotive systems and for increasing the lifespan of the engine.

2. Industrial Machinery In manufacturing plants where machinery operates under heavy loads, the need for high-performance oil seals becomes paramount. Machinery using the 32% 2047% 7% oil seal can operate efficiently without the risks of oil spillage or contamination.

3. Marine Equipment When dealing with marine applications, exposure to corrosive elements is a significant concern. Oil seals designed to withstand harsh marine environments while ensuring fluid retention are essential for the durability of such equipment.

4. Aerospace In the aerospace industry, equipment requires seals that can endure extreme conditions. The ability of the 32% 2047% 7% oil seal to maintain integrity under varied temperature and pressure conditions makes it ideal for such applications.

Conclusion

The significance of the 32% 2047% 7% oil seal goes beyond its simple function of sealing. It embodies advanced engineering solutions aimed at enhancing the performance, efficiency, and longevity of machinery across various sectors. By understanding the composition and appropriate applications of such seals, industries can make informed decisions about their machinery maintenance and operational strategies. As technology continues to evolve, so too will the designs and materials of oil seals, promising even greater capabilities for the future.

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

-

Unleash the Power of Your Hydraulic Systems with Our Premium Seal Kits

NewsAug.06,2025

-

Specialized Hydraulic Seal Kits for Breakers, Pistons, and Presses

NewsAug.06,2025

-

Revitalize Hydraulic Systems with Premium Repair and Seal Kits

NewsAug.06,2025

-

Fortify Your Cylinders with Premium Sealing Solutions

NewsAug.06,2025

-

Elevate Hydraulic System Reliability with Specialized Seal Kits

NewsAug.06,2025

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

Products categories