Feb . 13, 2025 19:25 Back to list

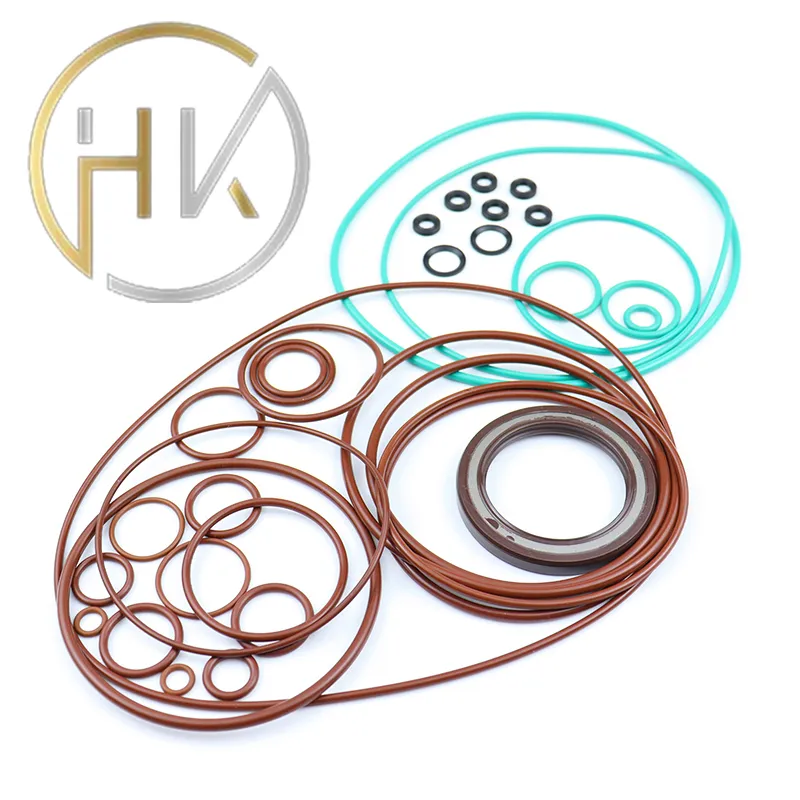

185*205*11 Rubber Oil Seal From Tcv NBR FKM High Pressure Oil Seal Tcv Oil Seal

One mustn't overlook the trustworthiness of brands that manufacture and supply these oil seals. A reputable supplier ensures that their products consistently meet quality standards, thus earning the trust of customers and professionals alike. These companies subject their products to rigorous testing procedures, guaranteeing that each seal is built to last and perform under specified conditions. As an industry expert, knowing which brands to trust can make all the difference in choosing components that deliver value over time. In the realm of aftermarket parts, the 22x35x7 oil seal has emerged as an indispensable asset, making it a highly sought-after component in repair and maintenance. Mechanics and engineers often stock these seals as part of their essential tools, appreciating their role in preemptive maintenance strategies. Given the potential downtime and repair costs associated with seal failures, using a reliable 22x35x7 oil seal is a preventive measure that pays off substantially over time. In practical scenarios, the usage of the 22x35x7 oil seal is diverse. From preventing oil leakage in a compact car engine to ensuring hydraulic cylinders in an industrial setting function smoothly, this oil seal holds its fort. Integration into any system offers peace of mind, knowing that a critical element of machinery is securely protected against the otherwise inevitable wear and degradation. As machinery and vehicles become increasingly sophisticated, the demand for precision parts that can keep up with advanced engineering continues to grow. The 22x35x7 oil seal fits seamlessly into this narrative, exemplifying how small components play a pivotal role in large mechanical ecosystems. To manufacturers, mechanics, and maintenance professionals, the assurance of a machine running at peak efficiency with minimal risk of oil seepage embodies the true value of investing in well-crafted oil seals. In conclusion, the 22x35x7 oil seal may seem minor in the grand scheme of mechanical components, yet its importance cannot be understated. With solid experience and expertise, these seals uphold authoritative roles across various industries, earning unmatched trust through consistently reliable performance. Investing in high-quality, reliable seals is synonymous with investing in the longevity and efficiency of machinery, underscoring the critical contribution of the 22x35x7 oil seal in today's fast-evolving technological landscape.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories