Current location:Home > hub grease seal >

hub grease seal

2025-08-15 08:52

2025-08-15 08:24

2025-08-15 08:20

The sealing effectiveness of a high pressure lip seal is influenced by several factors, including the choice of elastomer, the design of the lip, the quality of the shaft surface, and the operating temperature. The elastomer must be resistant to the specific fluid or gas being sealed, while the lip design should allow for minimal friction and wear. The shaft surface must be smooth to prevent damage to the seal, and the operating temperature must fall within the acceptable range of the seal material The shaft surface must be smooth to prevent damage to the seal, and the operating temperature must fall within the acceptable range of the seal material The shaft surface must be smooth to prevent damage to the seal, and the operating temperature must fall within the acceptable range of the seal material The shaft surface must be smooth to prevent damage to the seal, and the operating temperature must fall within the acceptable range of the seal material

The shaft surface must be smooth to prevent damage to the seal, and the operating temperature must fall within the acceptable range of the seal material The shaft surface must be smooth to prevent damage to the seal, and the operating temperature must fall within the acceptable range of the seal material high pressure lip seal.

high pressure lip seal.

The shaft surface must be smooth to prevent damage to the seal, and the operating temperature must fall within the acceptable range of the seal material The shaft surface must be smooth to prevent damage to the seal, and the operating temperature must fall within the acceptable range of the seal material

The shaft surface must be smooth to prevent damage to the seal, and the operating temperature must fall within the acceptable range of the seal material The shaft surface must be smooth to prevent damage to the seal, and the operating temperature must fall within the acceptable range of the seal material high pressure lip seal.

high pressure lip seal.

...

2025-08-15 07:55

2025-08-15 07:34

4 pu oil seal. Marine Protecting boat engines and hydraulic systems from water and contaminants.

pu oil seal. Marine Protecting boat engines and hydraulic systems from water and contaminants.

pu oil seal. Marine Protecting boat engines and hydraulic systems from water and contaminants.

pu oil seal. Marine Protecting boat engines and hydraulic systems from water and contaminants.

...

2025-08-15 07:31

2025-08-15 07:24

2025-08-15 07:08

2025-08-15 06:36

2025-08-15 06:34

Latest articles

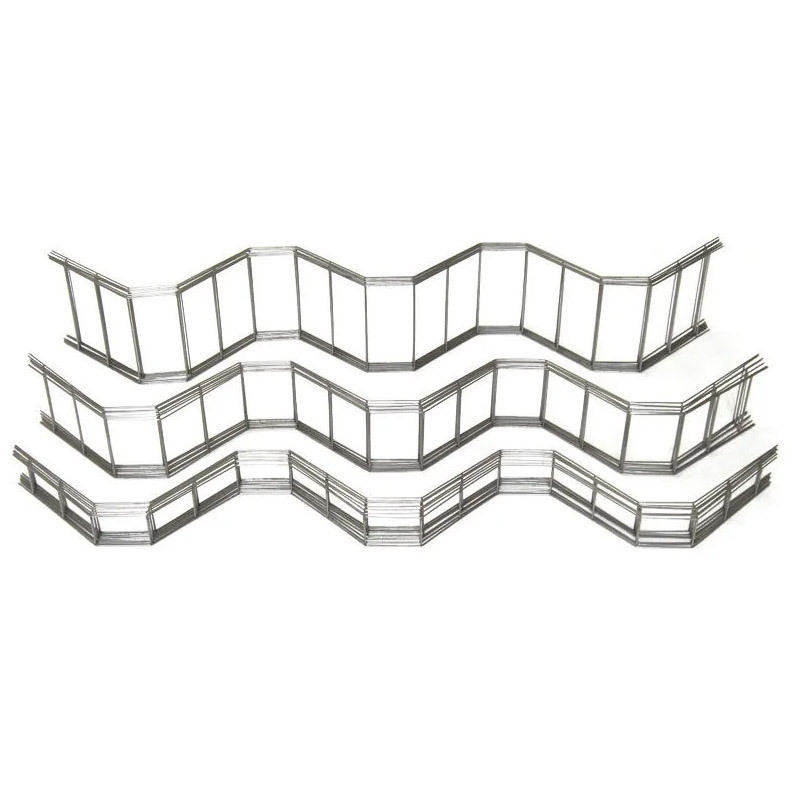

1 steel welded wire fabric. Improved Strength and Durability By distributing loads more effectively, steel welded wire fabric enhances the overall strength and durability of structures.

steel welded wire fabric. Improved Strength and Durability By distributing loads more effectively, steel welded wire fabric enhances the overall strength and durability of structures.

steel welded wire fabric. Improved Strength and Durability By distributing loads more effectively, steel welded wire fabric enhances the overall strength and durability of structures.

steel welded wire fabric. Improved Strength and Durability By distributing loads more effectively, steel welded wire fabric enhances the overall strength and durability of structures.In addition to its corrosion resistance, PVC galvanized wire is also known for its strength and durability. The combination of galvanizing and PVC coating enhances the wire's tensile strength, making it suitable for demanding applications that require a strong and long-lasting material. Whether used for building structures, securing livestock, or creating wire mesh, PVC galvanized wire can withstand heavy loads and remain intact over time.