Current location:Home > Hebei Hankai tcv oil seal >

Hebei Hankai tcv oil seal

2025-08-14 08:11

In addition to its sealing capabilities, the front hub oil seal also plays a role in reducing noise and vibration in the vehicle front hub oil seal. As the seal rotates with the wheel hub, it creates a damping effect that helps to absorb and reduce vibrations and noise. This is particularly important in vehicles that are used for long distances or in harsh driving conditions, where noise and vibration can become a significant issue.

front hub oil seal. As the seal rotates with the wheel hub, it creates a damping effect that helps to absorb and reduce vibrations and noise. This is particularly important in vehicles that are used for long distances or in harsh driving conditions, where noise and vibration can become a significant issue.

front hub oil seal. As the seal rotates with the wheel hub, it creates a damping effect that helps to absorb and reduce vibrations and noise. This is particularly important in vehicles that are used for long distances or in harsh driving conditions, where noise and vibration can become a significant issue.

front hub oil seal. As the seal rotates with the wheel hub, it creates a damping effect that helps to absorb and reduce vibrations and noise. This is particularly important in vehicles that are used for long distances or in harsh driving conditions, where noise and vibration can become a significant issue.

...

2025-08-14 07:27

2025-08-14 07:22

2025-08-14 06:54

2025-08-14 06:41

2025-08-14 06:32

In addition to preventing leaks, oil seals also keep out dust, dirt, and other contaminants that could damage the components inside the equipment

20x35x7 oil seal. By sealing out these harmful particles, the oil seal helps to maintain the cleanliness and integrity of the mechanical system, prolonging its service life and reducing the need for costly repairs and replacements.

20x35x7 oil seal. By sealing out these harmful particles, the oil seal helps to maintain the cleanliness and integrity of the mechanical system, prolonging its service life and reducing the need for costly repairs and replacements.

...

2025-08-14 06:19

2025-08-14 06:16

2025-08-14 06:08

2025-08-14 05:37

Latest articles

Furthermore, dust lip seals also contribute to the overall efficiency and reliability of machinery

dust lip seal. By sealing off critical components from external contaminants, these seals help to reduce maintenance requirements and downtime, saving time and money in the long run. With a properly functioning dust lip seal in place, machinery operators can rest assured that their equipment is protected and operating at peak performance levels.

dust lip seal. By sealing off critical components from external contaminants, these seals help to reduce maintenance requirements and downtime, saving time and money in the long run. With a properly functioning dust lip seal in place, machinery operators can rest assured that their equipment is protected and operating at peak performance levels.

One innovative solution for dust sealing is the use of high-performance elastomeric seals, which provide a flexible barrier against dust ingress. These seals can withstand harsh conditions, resist degradation from chemicals and weathering, and maintain their effectiveness over time These seals can withstand harsh conditions, resist degradation from chemicals and weathering, and maintain their effectiveness over time These seals can withstand harsh conditions, resist degradation from chemicals and weathering, and maintain their effectiveness over time These seals can withstand harsh conditions, resist degradation from chemicals and weathering, and maintain their effectiveness over time

These seals can withstand harsh conditions, resist degradation from chemicals and weathering, and maintain their effectiveness over time These seals can withstand harsh conditions, resist degradation from chemicals and weathering, and maintain their effectiveness over time dust sealing. Another approach is the utilization of air curtains, which create a pressurized flow of air to prevent dust particles from entering or escaping an area.

dust sealing. Another approach is the utilization of air curtains, which create a pressurized flow of air to prevent dust particles from entering or escaping an area.

These seals can withstand harsh conditions, resist degradation from chemicals and weathering, and maintain their effectiveness over time These seals can withstand harsh conditions, resist degradation from chemicals and weathering, and maintain their effectiveness over time

These seals can withstand harsh conditions, resist degradation from chemicals and weathering, and maintain their effectiveness over time These seals can withstand harsh conditions, resist degradation from chemicals and weathering, and maintain their effectiveness over time dust sealing. Another approach is the utilization of air curtains, which create a pressurized flow of air to prevent dust particles from entering or escaping an area.

dust sealing. Another approach is the utilization of air curtains, which create a pressurized flow of air to prevent dust particles from entering or escaping an area.Proper installation of oil seals is essential for their effective performance. The seals must be installed with precision to ensure a tight and secure fit, preventing any gaps or leaks that could compromise the pump's operation

oil seal for pump. Regular maintenance and inspection of the oil seals are also crucial to identify any signs of wear or damage that may require replacement.

oil seal for pump. Regular maintenance and inspection of the oil seals are also crucial to identify any signs of wear or damage that may require replacement.

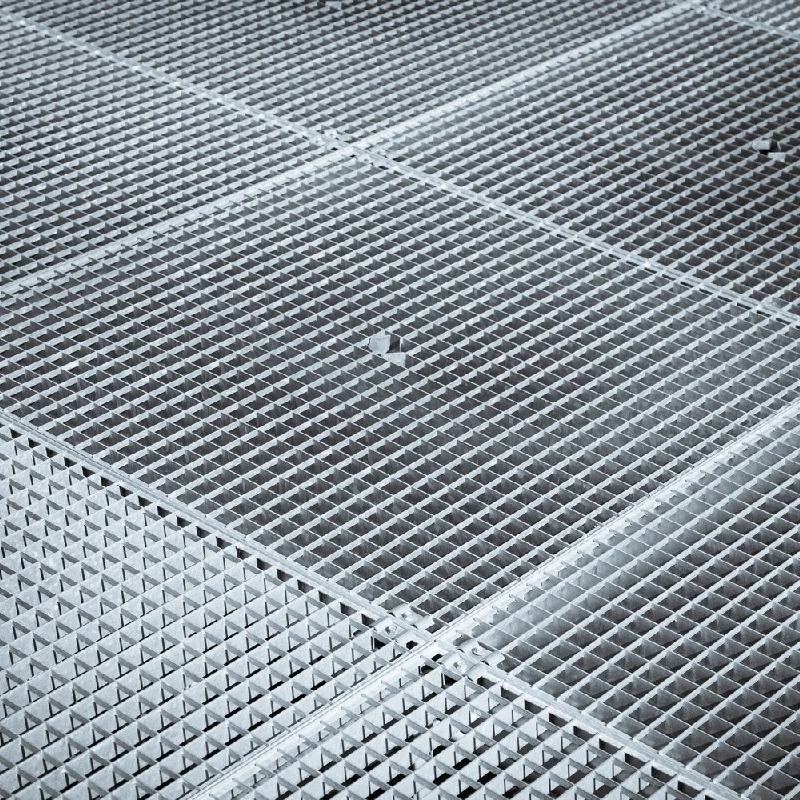

Safety is another key benefit of steel grating flooring. Its open design allows for quick drainage of water, oil, and other liquids, significantly reducing the risk of slips and falls in industrial settings. Furthermore, the grating's surface can be treated with anti-slip coatings or patterns, enhancing safety even further. This makes it an ideal choice for environments where safety is a top priority, such as chemical plants and food processing facilities.

steel grating flooring