Current location:Home > hydraulic motor oil seal >

hydraulic motor oil seal

2025-08-16 07:55

2025-08-16 07:42

...

2025-08-16 07:37

2025-08-16 07:33

2025-08-16 07:25

2025-08-16 07:00

2025-08-16 06:30

2025-08-16 06:17

Without a properly functioning oil seal, hydraulic motors can experience leaks that can lead to a loss of hydraulic fluid. This not only reduces the efficiency of the system but can also cause damage to the motor itself. In severe cases, a leaky oil seal can result in a complete failure of the hydraulic motor, leading to costly repairs and downtime for the equipment

hydraulic motor oil seal.

hydraulic motor oil seal.

...

2025-08-16 05:52

2025-08-16 05:36

Latest articles

In addition to material selection, the design of high-speed rotary shaft seals is also critical to their performance. The seals must be carefully engineered to maintain a tight seal around the shaft while allowing for smooth rotation

high speed rotary shaft seals. This is achieved through precise machining and assembly processes that ensure the seals are properly installed and functioning correctly.

high speed rotary shaft seals. This is achieved through precise machining and assembly processes that ensure the seals are properly installed and functioning correctly.

To mitigate these issues, regular maintenance and inspection of the oil seals are essential hydraulic pump oil seal. This includes periodic checks for signs of wear, such as cracks or softening of the material, as well as monitoring for any seepage around the seal. Should replacement be necessary, it is crucial to use a seal that matches the manufacturer's specifications to ensure compatibility with the pump's operating conditions.

hydraulic pump oil seal. This includes periodic checks for signs of wear, such as cracks or softening of the material, as well as monitoring for any seepage around the seal. Should replacement be necessary, it is crucial to use a seal that matches the manufacturer's specifications to ensure compatibility with the pump's operating conditions.

hydraulic pump oil seal. This includes periodic checks for signs of wear, such as cracks or softening of the material, as well as monitoring for any seepage around the seal. Should replacement be necessary, it is crucial to use a seal that matches the manufacturer's specifications to ensure compatibility with the pump's operating conditions.

hydraulic pump oil seal. This includes periodic checks for signs of wear, such as cracks or softening of the material, as well as monitoring for any seepage around the seal. Should replacement be necessary, it is crucial to use a seal that matches the manufacturer's specifications to ensure compatibility with the pump's operating conditions.The material selection for hydraulic shaft seals is crucial, as it directly impacts the seal's durability and effectiveness. Materials like rubber, polyurethane, and PTFE (Teflon) are commonly used due to their resistance to chemicals, temperature fluctuations, and wear Materials like rubber, polyurethane, and PTFE (Teflon) are commonly used due to their resistance to chemicals, temperature fluctuations, and wear Materials like rubber, polyurethane, and PTFE (Teflon) are commonly used due to their resistance to chemicals, temperature fluctuations, and wear Materials like rubber, polyurethane, and PTFE (Teflon) are commonly used due to their resistance to chemicals, temperature fluctuations, and wear

Materials like rubber, polyurethane, and PTFE (Teflon) are commonly used due to their resistance to chemicals, temperature fluctuations, and wear Materials like rubber, polyurethane, and PTFE (Teflon) are commonly used due to their resistance to chemicals, temperature fluctuations, and wear hydraulic shaft seal. The choice of material depends on factors such as the type of fluid, operating pressure, and speed of the shaft.

hydraulic shaft seal. The choice of material depends on factors such as the type of fluid, operating pressure, and speed of the shaft.

Materials like rubber, polyurethane, and PTFE (Teflon) are commonly used due to their resistance to chemicals, temperature fluctuations, and wear Materials like rubber, polyurethane, and PTFE (Teflon) are commonly used due to their resistance to chemicals, temperature fluctuations, and wear

Materials like rubber, polyurethane, and PTFE (Teflon) are commonly used due to their resistance to chemicals, temperature fluctuations, and wear Materials like rubber, polyurethane, and PTFE (Teflon) are commonly used due to their resistance to chemicals, temperature fluctuations, and wear hydraulic shaft seal. The choice of material depends on factors such as the type of fluid, operating pressure, and speed of the shaft.

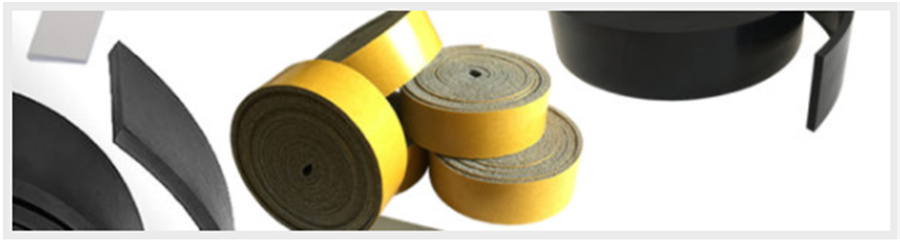

hydraulic shaft seal. The choice of material depends on factors such as the type of fluid, operating pressure, and speed of the shaft.5. Durability and Longevity Typically made from materials like silicone, foam, or rubber, 4-inch weather stripping is designed to withstand various weather conditions. Its durability ensures that it maintains its shape and effectiveness over time, providing long-term benefits.

4 inch weather stripping

In addition to protecting the interior of your car, the weather seal car also helps to reduce noise levels while driving. It creates a tight seal that minimizes wind noise and vibrations, providing a quieter and more enjoyable driving experience

weather seal car. This is especially important for long road trips or daily commutes, where comfort and noise levels play a significant role in your overall driving experience.

weather seal car. This is especially important for long road trips or daily commutes, where comfort and noise levels play a significant role in your overall driving experience.