Current location:Home > 40 80 10 oil seal >

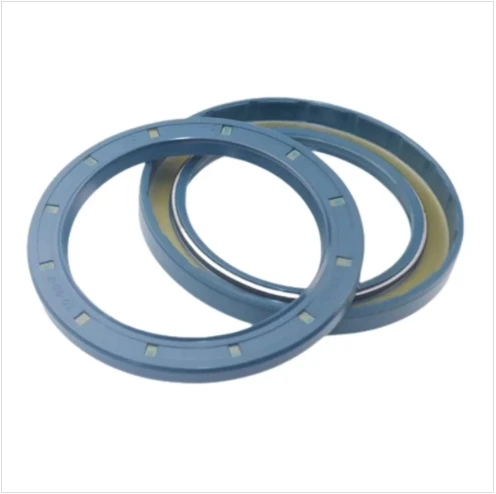

40 80 10 oil seal

2025-08-14 10:21

2025-08-14 10:08

2025-08-14 09:57

2025-08-14 09:35

2025-08-14 09:31

2025-08-14 09:16

2025-08-14 08:58

2025-08-14 08:36

2025-08-14 08:27

2025-08-14 08:04

Latest articles

Furthermore, the 32% attributed to operator skill highlights the human element in machine operation 20 32 6 oil seal. A skilled operator understands the value of regular checks and replacements of parts like oil seals. They recognize that these small components contribute to the larger goal of minimizing downtime and maximizing productivity. Their vigilance ensures that the machinery operates at peak condition, translating into cost savings and improved workflow efficiency.

20 32 6 oil seal. A skilled operator understands the value of regular checks and replacements of parts like oil seals. They recognize that these small components contribute to the larger goal of minimizing downtime and maximizing productivity. Their vigilance ensures that the machinery operates at peak condition, translating into cost savings and improved workflow efficiency.

20 32 6 oil seal. A skilled operator understands the value of regular checks and replacements of parts like oil seals. They recognize that these small components contribute to the larger goal of minimizing downtime and maximizing productivity. Their vigilance ensures that the machinery operates at peak condition, translating into cost savings and improved workflow efficiency.

20 32 6 oil seal. A skilled operator understands the value of regular checks and replacements of parts like oil seals. They recognize that these small components contribute to the larger goal of minimizing downtime and maximizing productivity. Their vigilance ensures that the machinery operates at peak condition, translating into cost savings and improved workflow efficiency.Once the type of seal has been identified, the next step is to remove the old seal from the system. This can be a delicate process, as care must be taken not to damage any other components of the hydraulic system. In some cases, specialized tools may be required to safely and effectively remove the seal.

The importance of oil seals in hydraulic systems cannot be overstated oil seal hydraulic. A faulty or worn-out seal can lead to fluid leaks, causing a drop in system pressure and reduced performance. Moreover, the ingress of contaminants can damage sensitive components, leading to costly repairs or even complete system failure. Therefore, regular inspection and timely replacement of oil seals are essential for maintaining the overall health and longevity of hydraulic systems.

oil seal hydraulic. A faulty or worn-out seal can lead to fluid leaks, causing a drop in system pressure and reduced performance. Moreover, the ingress of contaminants can damage sensitive components, leading to costly repairs or even complete system failure. Therefore, regular inspection and timely replacement of oil seals are essential for maintaining the overall health and longevity of hydraulic systems.

oil seal hydraulic. A faulty or worn-out seal can lead to fluid leaks, causing a drop in system pressure and reduced performance. Moreover, the ingress of contaminants can damage sensitive components, leading to costly repairs or even complete system failure. Therefore, regular inspection and timely replacement of oil seals are essential for maintaining the overall health and longevity of hydraulic systems.

oil seal hydraulic. A faulty or worn-out seal can lead to fluid leaks, causing a drop in system pressure and reduced performance. Moreover, the ingress of contaminants can damage sensitive components, leading to costly repairs or even complete system failure. Therefore, regular inspection and timely replacement of oil seals are essential for maintaining the overall health and longevity of hydraulic systems.3. Durability and Longevity Made from high-quality materials such as cast iron or composite materials, inset manhole lids are engineered to endure the wear and tear of urban environments. Their design can also help distribute weight more evenly than traditional lids, potentially extending their lifespan and reducing the frequency of replacements.