Current location:Home > defender hub seal >

defender hub seal

2025-08-16 11:09

2025-08-16 10:53

2025-08-16 10:47

2025-08-16 10:26

2025-08-16 10:20

2025-08-16 10:18

2025-08-16 10:06

2025-08-16 09:08

2025-08-16 09:06

2025-08-16 09:02

Latest articles

In addition to their durability, metal oil seals are also highly effective at containing lubricants and preventing contamination. By creating a tight seal between stationary and moving components, these seals prevent oil from leaking out and debris from entering the system. This helps to maintain the cleanliness and efficiency of the machinery, reducing the risk of damage and downtime.

Moreover, custom made oil seals can be manufactured from a variety of materials to suit the specific needs of the application. Whether it is for high-temperature environments, high-pressure systems, or corrosive chemicals, custom-made seals can be designed with the appropriate material to withstand the demands of the operating conditions. This not only extends the durability of the seals but also enhances the overall efficiency and reliability of the equipment.

The primary function of these seal kits is to maintain system cleanliness and ensure leak-free operation. A damaged or worn seal can lead to significant issues such as reduced efficiency, increased maintenance costs, and potential environmental hazards due to hydraulic fluid spills A damaged or worn seal can lead to significant issues such as reduced efficiency, increased maintenance costs, and potential environmental hazards due to hydraulic fluid spills A damaged or worn seal can lead to significant issues such as reduced efficiency, increased maintenance costs, and potential environmental hazards due to hydraulic fluid spills A damaged or worn seal can lead to significant issues such as reduced efficiency, increased maintenance costs, and potential environmental hazards due to hydraulic fluid spills

A damaged or worn seal can lead to significant issues such as reduced efficiency, increased maintenance costs, and potential environmental hazards due to hydraulic fluid spills A damaged or worn seal can lead to significant issues such as reduced efficiency, increased maintenance costs, and potential environmental hazards due to hydraulic fluid spills hydraulic motor seal kit. Therefore, regular inspection and timely replacement of seals using a quality hydraulic motor seal kit are crucial for optimal performance.

hydraulic motor seal kit. Therefore, regular inspection and timely replacement of seals using a quality hydraulic motor seal kit are crucial for optimal performance.

A damaged or worn seal can lead to significant issues such as reduced efficiency, increased maintenance costs, and potential environmental hazards due to hydraulic fluid spills A damaged or worn seal can lead to significant issues such as reduced efficiency, increased maintenance costs, and potential environmental hazards due to hydraulic fluid spills

A damaged or worn seal can lead to significant issues such as reduced efficiency, increased maintenance costs, and potential environmental hazards due to hydraulic fluid spills A damaged or worn seal can lead to significant issues such as reduced efficiency, increased maintenance costs, and potential environmental hazards due to hydraulic fluid spills hydraulic motor seal kit. Therefore, regular inspection and timely replacement of seals using a quality hydraulic motor seal kit are crucial for optimal performance.

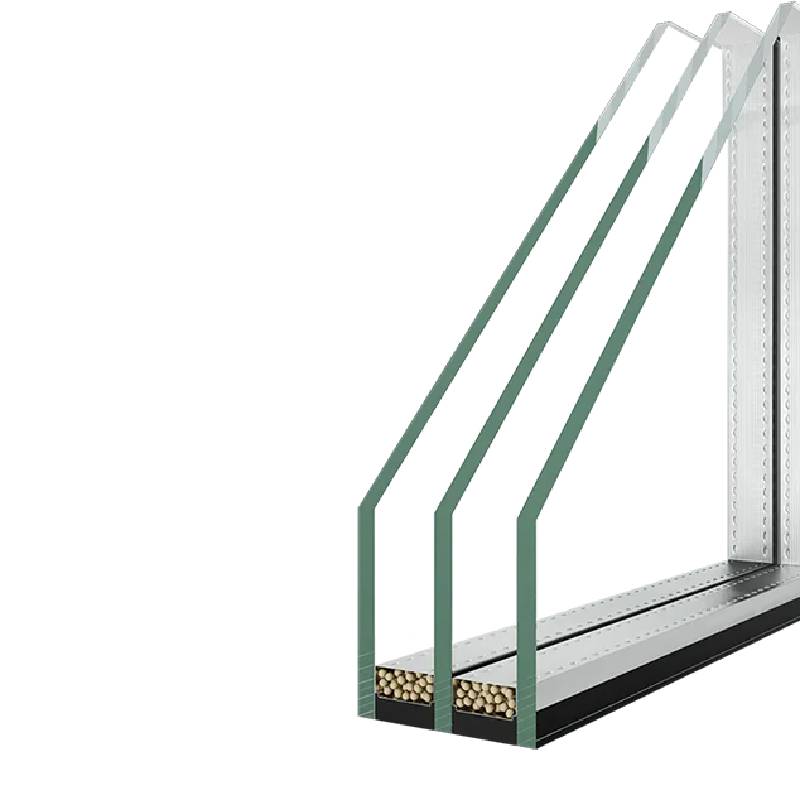

hydraulic motor seal kit. Therefore, regular inspection and timely replacement of seals using a quality hydraulic motor seal kit are crucial for optimal performance.Beveled low-e glass offers numerous advantages over traditional flat glassbeveled low e glass. For example, its beveled edges can help to reduce glare and improve privacy by making it more difficult for people outside to see inside a room . At the same time, the low-e coating helps to regulate indoor temperatures by reflecting infrared radiation from the sun back out into the atmosphere. This can lead to significant energy savings on heating and cooling bills over time.

. At the same time, the low-e coating helps to regulate indoor temperatures by reflecting infrared radiation from the sun back out into the atmosphere. This can lead to significant energy savings on heating and cooling bills over time.

. At the same time, the low-e coating helps to regulate indoor temperatures by reflecting infrared radiation from the sun back out into the atmosphere. This can lead to significant energy savings on heating and cooling bills over time.

. At the same time, the low-e coating helps to regulate indoor temperatures by reflecting infrared radiation from the sun back out into the atmosphere. This can lead to significant energy savings on heating and cooling bills over time.One of the main advantages of frosted glass is its versatility. It can be used in a variety of applications, including windows, doors, partitions, shower enclosures, and furniture. Frosted glass is a popular choice for bathroom windows and shower enclosures as it provides privacy while still allowing natural light to enter the space. In commercial settings, frosted glass is often used for office partitions to create a sense of privacy without sacrificing open space.

Mirror glass manufacturers must also take care to ensure that the mirror is free from defects, such as bubbles, scratches, or other imperfections. These defects can affect the quality of the reflection and make the mirror less effective. Manufacturers use quality control processes to identify and eliminate any defects before the mirror is shipped to customers

mirror glass manufacturers.

mirror glass manufacturers.