dust sealing

The mention of 55%, 80%, and 10% in relation to oil seals might reflect various metrics or considerations concerning their performance and application. For example, in many mechanical systems, seals can be categorized based on their efficiency, effectiveness in preventing leakage, and their material composition. A 55% rating might refer to a baseline performance measure for standard oil seals, whereas an 80% rating could indicate high-performance seals designed for rigorous applications. On the other hand, a 10% figure could relate to the failure rate or the operating conditions under which these seals can be compromised.

55 80 10 oil seal

It can be used for personal identification, as a signature on official documents, or even as an artistic embellishment on letters and packages It can be used for personal identification, as a signature on official documents, or even as an artistic embellishment on letters and packages

It can be used for personal identification, as a signature on official documents, or even as an artistic embellishment on letters and packages It can be used for personal identification, as a signature on official documents, or even as an artistic embellishment on letters and packages 35 52 8 seal. Its versatility makes it a popular choice among artists, writers, and professionals alike.

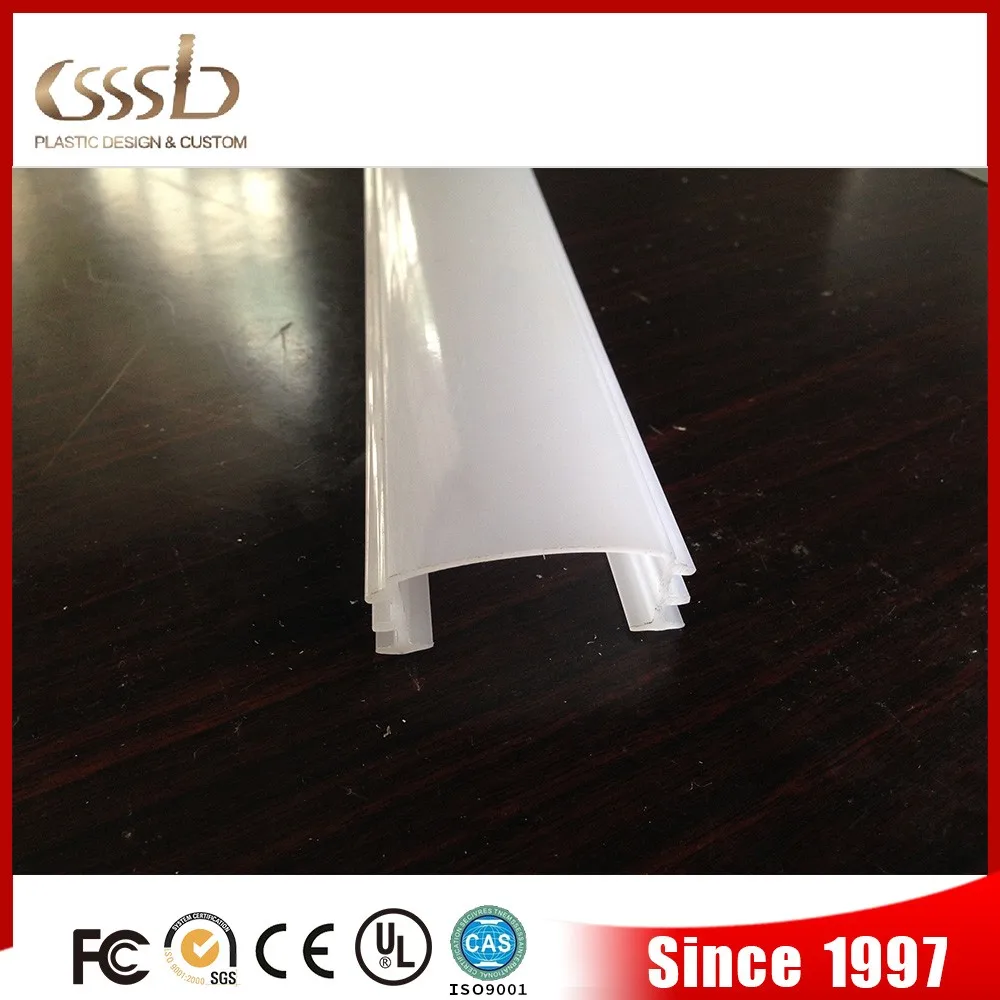

35 52 8 seal. Its versatility makes it a popular choice among artists, writers, and professionals alike.5. Cutting and Packaging Once the strips are complete, they are cut to size based on customer requirements. Quality control measures are typically implemented during this phase to ensure that the strips meet the specified dimensions and performance criteria. Finally, products are packaged carefully to protect them during transportation.

self adhesive sealing strip factory

Obtaining CE certification offers several advantages to manufacturers of flat aluminum coils. Firstly, it increases market access within the European Union. Many European countries require CE marking for construction materials and components, particularly those used in structural applications. By showcasing CE certification, manufacturers can demonstrate their commitment to quality and significantly enhance their competitiveness in the European market.

ce cetification flat aluminum coil