scraper seal hydraulic

wiper oil seal. If you notice any signs of oil leakage, such as oil spots or a strong smell of oil inside the vehicle, it is important to have the wiper oil seal checked and replaced if necessary.

Moreover, oil seal companies play a vital role in innovation and research to develop new materials and technologies that improve the performance and longevity of their seals. They invest in state-of-the-art manufacturing processes and quality control measures to ensure the reliability and efficiency of their products. Additionally, many companies offer technical support and consulting services to help their customers select the right seals for their applications and optimize their performance.

oil seal companies

combi oil seal. Made from high-quality materials and engineered to withstand the rigors of constant use, these seals can provide years of reliable service without requiring frequent replacement. This not only saves time and money but also minimizes downtime and disruption to production processes.

combi oil seal. Made from high-quality materials and engineered to withstand the rigors of constant use, these seals can provide years of reliable service without requiring frequent replacement. This not only saves time and money but also minimizes downtime and disruption to production processes. hydraulic pump oil seal. This includes periodic checks for signs of wear, such as cracks or softening of the material, as well as monitoring for any seepage around the seal. Should replacement be necessary, it is crucial to use a seal that matches the manufacturer's specifications to ensure compatibility with the pump's operating conditions.

hydraulic pump oil seal. This includes periodic checks for signs of wear, such as cracks or softening of the material, as well as monitoring for any seepage around the seal. Should replacement be necessary, it is crucial to use a seal that matches the manufacturer's specifications to ensure compatibility with the pump's operating conditions. Factors to consider include the operating conditions, such as temperature, pressure, and the type of fluid used Factors to consider include the operating conditions, such as temperature, pressure, and the type of fluid used

Factors to consider include the operating conditions, such as temperature, pressure, and the type of fluid used Factors to consider include the operating conditions, such as temperature, pressure, and the type of fluid used 5 inch hydraulic cylinder seal kit. Compatibility with the specific cylinder design and the quality of the seals are equally important. Always ensure that the seal kit you choose is from a reputable manufacturer and meets industry standards.

5 inch hydraulic cylinder seal kit. Compatibility with the specific cylinder design and the quality of the seals are equally important. Always ensure that the seal kit you choose is from a reputable manufacturer and meets industry standards.3. Pressure Maintenance In many applications, oil seals are designed to maintain pressure within a system. By preventing the exit of oil and the entrance of contaminants, they help in sustaining the necessary pressure levels for optimal operation. This function is especially important in hydraulic systems, where pressure plays a critical role in performance.

what is the function of oil seal

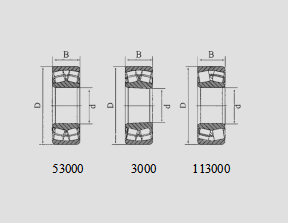

double row thrust ball bearing. The flat seat variant is suitable for applications with uniform load distribution, while the spherical seat type offers self-aligning capabilities, accommodating misalignments in the shaft and housing.

double row thrust ball bearing. The flat seat variant is suitable for applications with uniform load distribution, while the spherical seat type offers self-aligning capabilities, accommodating misalignments in the shaft and housing.