Current location:Home > Hebei Hankai hub oil seal >

Hebei Hankai hub oil seal

2025-08-14 19:01

When it comes to replacing the seals in a hydraulic cylinder, it is important to follow the manufacturer's guidelines and use the correct seal kit for the specific cylinder

. Using the wrong seals can result in leaks, reduced performance, or even damage to the cylinder itself.3 inch bore hydraulic cylinder seal kit

...

2025-08-14 18:19

2025-08-14 18:15

2025-08-14 17:58

2025-08-14 17:26

2025-08-14 17:23

2025-08-14 17:21

2025-08-14 17:14

Another benefit of PU oil seals is their resistance to a wide range of operating conditions. They can withstand high temperatures, high pressures, and harsh chemical environments without losing their sealing properties. This makes them ideal for use in demanding applications where other seals may fail.

...

2025-08-14 17:12

2025-08-14 17:04

Latest articles

The 20x30x7 oil seal is typically made from high-quality materials such as Nitrile Butadiene Rubber (NBR), a popular choice due to its excellent resistance to oils and fuels 20x30x7 oil seal. The design incorporates a metal case for added strength and stability, ensuring the seal can withstand the pressures and temperatures encountered in various industrial environments.

20x30x7 oil seal. The design incorporates a metal case for added strength and stability, ensuring the seal can withstand the pressures and temperatures encountered in various industrial environments.

20x30x7 oil seal. The design incorporates a metal case for added strength and stability, ensuring the seal can withstand the pressures and temperatures encountered in various industrial environments.

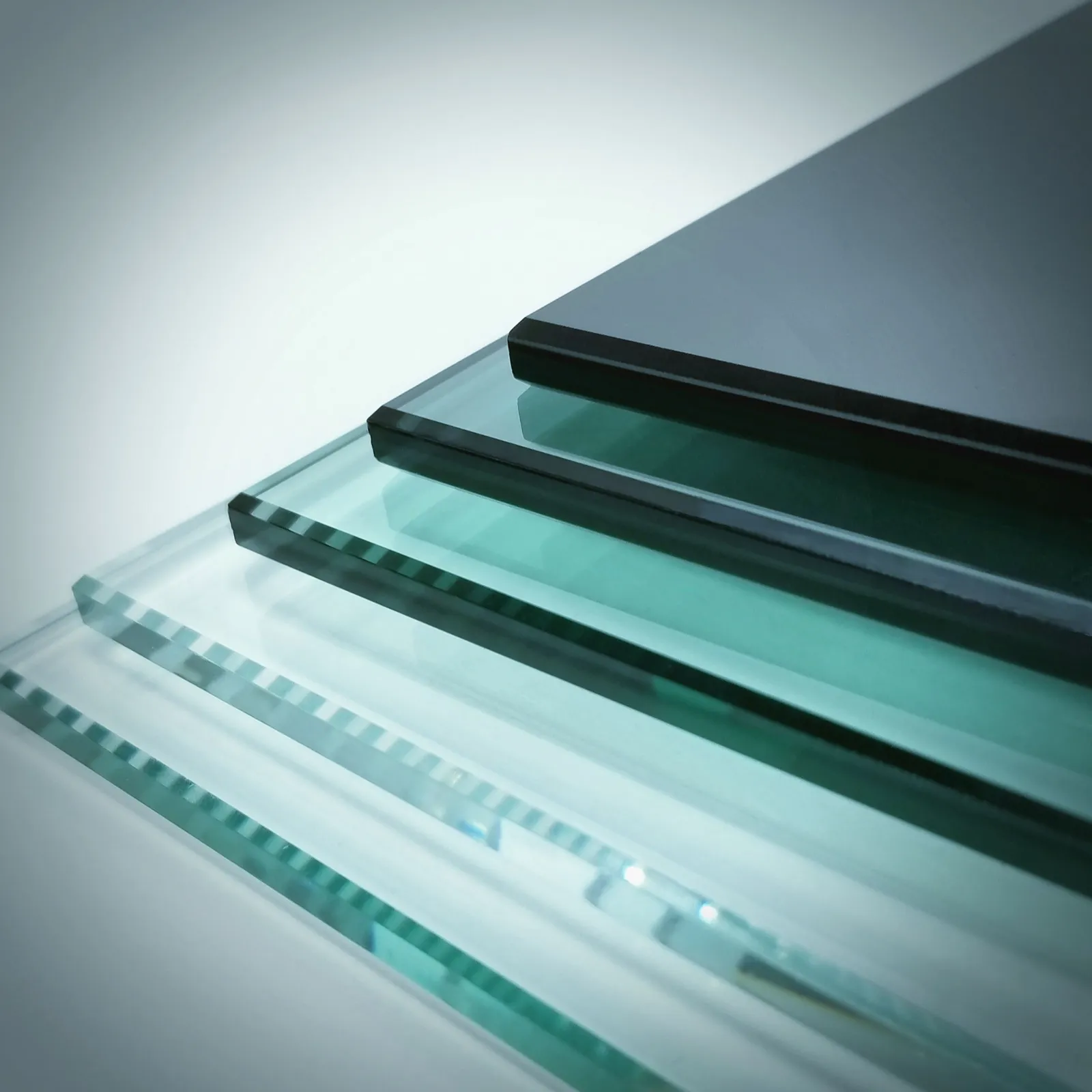

20x30x7 oil seal. The design incorporates a metal case for added strength and stability, ensuring the seal can withstand the pressures and temperatures encountered in various industrial environments.Moreover, reputable suppliers of 2mm float glass pride themselves on maintaining a consistently high product quality. They understand that the thinness of the glass demands a meticulous production process to prevent breakage and flaws They understand that the thinness of the glass demands a meticulous production process to prevent breakage and flaws They understand that the thinness of the glass demands a meticulous production process to prevent breakage and flaws They understand that the thinness of the glass demands a meticulous production process to prevent breakage and flaws

They understand that the thinness of the glass demands a meticulous production process to prevent breakage and flaws They understand that the thinness of the glass demands a meticulous production process to prevent breakage and flaws 2mm float glass supplier. As such, they employ stringent quality control measures from the melting phase to the packing stage, ensuring each sheet delivered to clients is free from waves, bubbles, and distortions.

2mm float glass supplier. As such, they employ stringent quality control measures from the melting phase to the packing stage, ensuring each sheet delivered to clients is free from waves, bubbles, and distortions.

They understand that the thinness of the glass demands a meticulous production process to prevent breakage and flaws They understand that the thinness of the glass demands a meticulous production process to prevent breakage and flaws

They understand that the thinness of the glass demands a meticulous production process to prevent breakage and flaws They understand that the thinness of the glass demands a meticulous production process to prevent breakage and flaws 2mm float glass supplier. As such, they employ stringent quality control measures from the melting phase to the packing stage, ensuring each sheet delivered to clients is free from waves, bubbles, and distortions.

2mm float glass supplier. As such, they employ stringent quality control measures from the melting phase to the packing stage, ensuring each sheet delivered to clients is free from waves, bubbles, and distortions.The float glass production process begins with the melting of raw materials, including silica sand, soda ash, and limestone, at high temperatures. This molten mixture is then floated on top of molten tin, allowing the glass to spread evenly and form a continuous sheet. As the glass moves through the annealing lehr—a controlled cooling chamber—it gradually solidifies and is cut into standardized sheet sizes.

float glass sheets